Press brakes are big machines used to bend large sheets of metal, also the ACL's product such as bending dies for hydraulic press. They are critical industrial tools that we use in factories and construction sites. You might find it useful to understand how press brake price is determined if you want to purchase one. The cost of a press brake is determined by a number of different factors.

The size of the press brake is one thing that will have an effect on the price. Larger press brakes, which can bend larger metal sheets, cost more than smaller ones. The specifications of the machine are also important. As with all equipment, press brakes packed with special features and advanced technology will be more expensive than simpler models.

One more factor to consider is the press brake brand. Some companies are known for a better quality of goods, which can raise the price. But there are also smaller brands with decent quality for a lower price. Before you buy, you need to know about different brands, and how people view them.

Hydraulic press brakes are preferred for their great accuracy and high power, identical to stainless steel tube bender built by ACL. They use pneumatic fluid, which they pass on to the metal, allowing for precise results. Hydraulic press brakes can, however, always be more expensive than mechanical press brakes used.

When considering press brake prices, consider your needs and your budget, the same as ACL's laser machine supplier. If you are running some small jobs, a simple mechanical press brake may do the trick. However, If the high precision is required for a big project, you will probably want to invest more into a hydraulic press brake.

One more affordable option is discovering basic press brakes which are much cheaper and only offer their fundamental features, along with the cnc laser created by ACL. While these machines may be pared down compared to pricier models without all the bells and whistles, they can still do the job quite nicely on small projects.

In short, purchasing a press brake is a smart move for any business needing to bend metal, as well as the ACL's press tool types. Learning what goes into press brake prices, how they compare against one another, and what you might be willing to pay in the interest of budget allows you to make an informed decision that benefits your business for years to come.

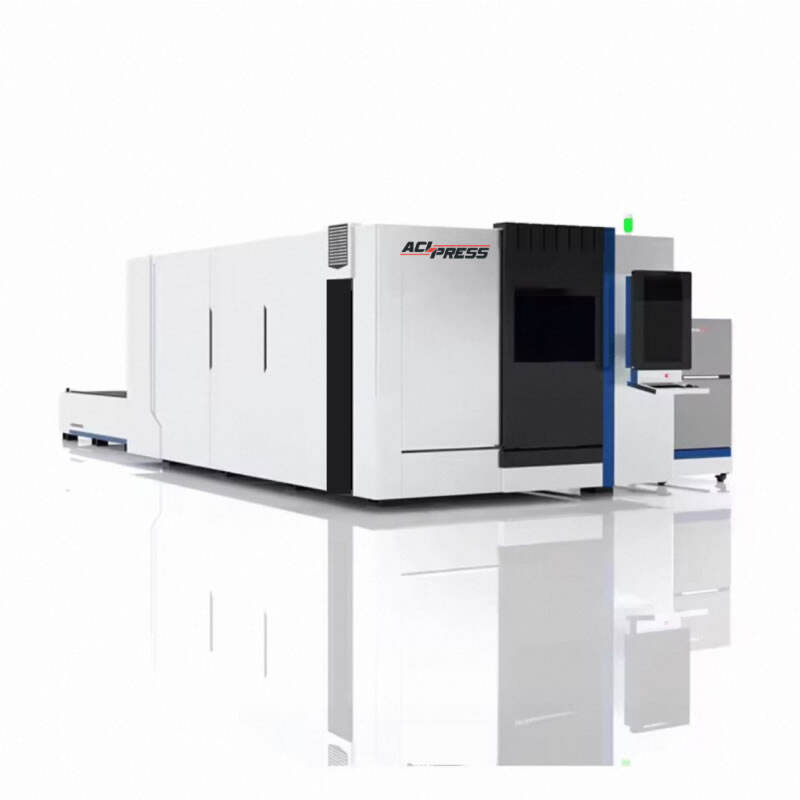

Press brake price offers exceptional processing and product customization capabilities. ACLPRESS is highly knowledgeable of the specifics of sheet metal bending, which allows it to provide customers with the most efficient solutions based on their production drawings, needs, and conditions.

ACLPRESS Press brake price a robust production capacity with numerous CNC machines which include a CNC Gantry machining centre CNC four-axis machining centers and CNC precise grinding machines. It also operates a heat treatment workshop treats various spare parts swiftly and precisely. It also a debugging centre to ensure the orders of customers are fulfilled punctually and accurately.

ACLPRESS is not just home to the Press brake price of precision equipment for the processing of press brakes but also various precision inspecting tools to spot defects in the product, and ensure reliability and stability. We also offer a comprehensive after-sales support.

ACLPRESS is Press brake price involved in the steel metal bending industry for more than 20 years. With a wealth of sales and production expertise, we are able to assist customers in addressing and resolving issues across a wide range of products. Our technical staff is available all-hours technical support to ensure prompt and efficient service delivery.