A brake press is a special machine that helps working people shape metal. It is like a giant muscular helper that can reshape metal as you want. Think of a huge hand that can delicately squeeze and draw metal to form awesome items like parts for vehicles or parts for airplanes! It is a very important machine at the factories where human-made various metal items.

A long time ago, metal was bent by the hammering of workers. This was low-hanging fruit and quite time intensive. They would strike metal in a thousand different ways for hours and hours, trying to make it fit the product. Their hands would tire, and sometimes the metal wouldn’t bend the way they hoped. Now, everything is easy with the press brakes! These machines bend the metal fast, without getting hurt.

Strong pressure is used for pushing and shaping metals using press brakes. It’s kind of like the machine gives the metal a big, gentle hug. Factories are capable of producing more products, at a greater speed, than any factory has ever produced. Now, instead of spending hours on a single piece of metal, workers can make dozens of them in minutes!

They are great and make a lot of different things. They can shape metal into all kinds of forms. Some press brakes are large, some are small. But they all perform the same vital function — enabling workers to make parts out of metal. These machines can create everything from parts for cars and airplanes to computers and many other products we use daily.

There are even better press brakes to keep the workers safe. It’s safer than the old tools that might hurt people’s hands.” It produces metal parts that are just right — neither too bent and neither too straight. Press brakes are the most preferred machines in factories; As they do the correct metal pieces in a short span of time.

Say you have small jobs and big jobs, you have press brakes for big jobs, you have press brakes for small jobs. Some can create giant parts for heavy machinery, while others can create tiny parts for small devices. Whatever the need of a factory, there is a press brake that helps!

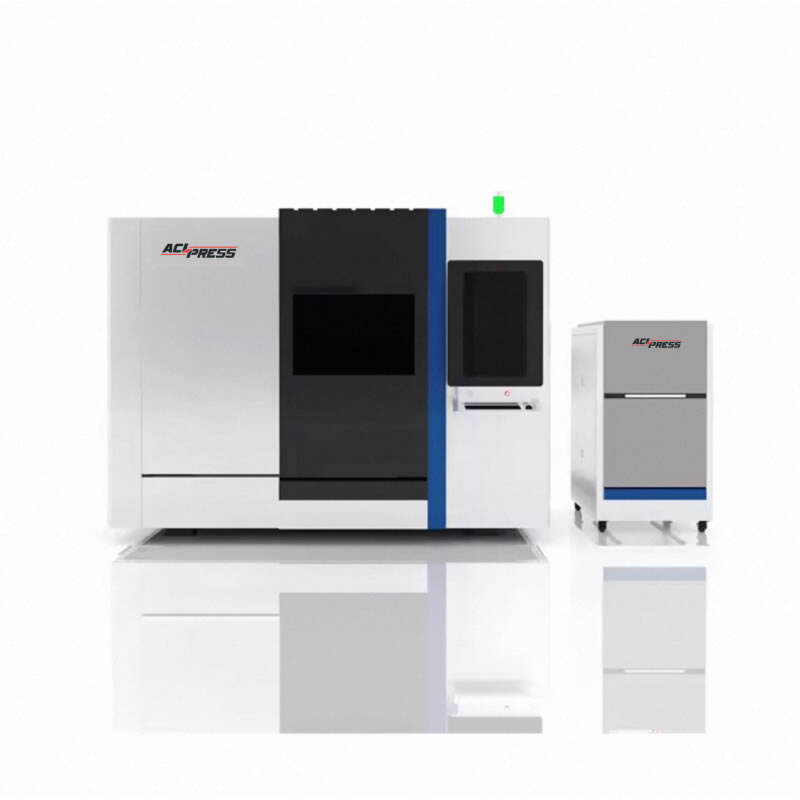

ACL, among other companies, manufactures really nice press brakes. They do everything they can to build machines that are safe and simple to use. So you know, these companies do not spend every minute of the day thinking up ways to slightly improve press brakes. They aim to assist laborers in rapidly and thoroughly mold metal aspects.

ACLPRESS press brake exceptional processing and capability to customise products. It is well-versed in the specifics of the bending of sheet metal which allows it to provide customers optimal solutions built on production drawings specifications, needs, and current conditions to help them achieve meeting their goals in business.

ACLPRESS is actively involved in the steel metal bending industry for more than press brake. With a wealth of sales and production experience, we can aid customers with resolving problems across a variety of product applications. Our team of experts provides 24 hours of technical assistance to ensure quick and high quality service delivery.

ACLPRESS offers not just the most extensive selection of precision equipment for the processing of press brakes but also numerous precision inspecting tools to spot issues with products, press brake durability and reliability. In addition, we provide comprehensive after-sales service.

ACLPRESS boasts a significant production capacity due to its CNC machines like a CNC Gantry Machine press brake and CNC precision grinders. The company also an industrial heat treatment facility processes various spare parts quickly and precisely. The facility also houses a debugging center to ensure customer orders are completed promptly and precisely.