For example, have you ever wanted to create your own unique prints on shirts, bags, or paper? If so, you’re in luck! With a little practice, using stamps and presses are a process that can enable you to create those designs you fantasize about. You can do lots of creative things with these cool techniques to make your own personalized unique designs on any surface, so you can be creative in different ways.

For press brake, one of the most popular surfaces is fabric. Plain t-shirts, bags, or hats can sometimes be bought at craft stores and are just waiting for your magic touch. After collecting all your supplies, use a variety of stamps/pressing methods to transform those ordinary items into a tailored gift made especially for you. Special fabric ink can also be used to make your designs even more vibrant! This style of ink dries bright and colorful, as well as ensuring your designs last a long time, even after being washed.

Here’s compressed what we had to say about compression. Unlike heat transfer, which is a method of using heat and pressure to transfer the desired design or picture into the surface. This neat trick is used a lot across various industries, like printing and embroidery.

This means when you’re pressing your design onto the fabric, it ensures that it remains on there for the long term. This means you no longer need to worry about your design fading or rubbing off easily. Plus, pressing is a fast, easy way to produce many designs at one time. This means it can work great with big projects, such as creating t-shirts for a team or bags for an event!

If you are new to brake press, it can be a little bit tricky at first. But don’t worry! Getting started is so easily doable, actually. We’ve put together a few easy steps that will assist you in designing your creations:

Choose your stamp: Browse the stamps at a craft store and decide what you want to use. There are so many options to choose from, so take your time and find the logo that you think best represents you or what you are trying to say.

Make sure you use good quality ink: The kind of ink you use to fill your outlines can make a huge difference to your final design. It makes a lot of sense to spend your money on quality ink that will make your designs appear more stunning and last a long time.

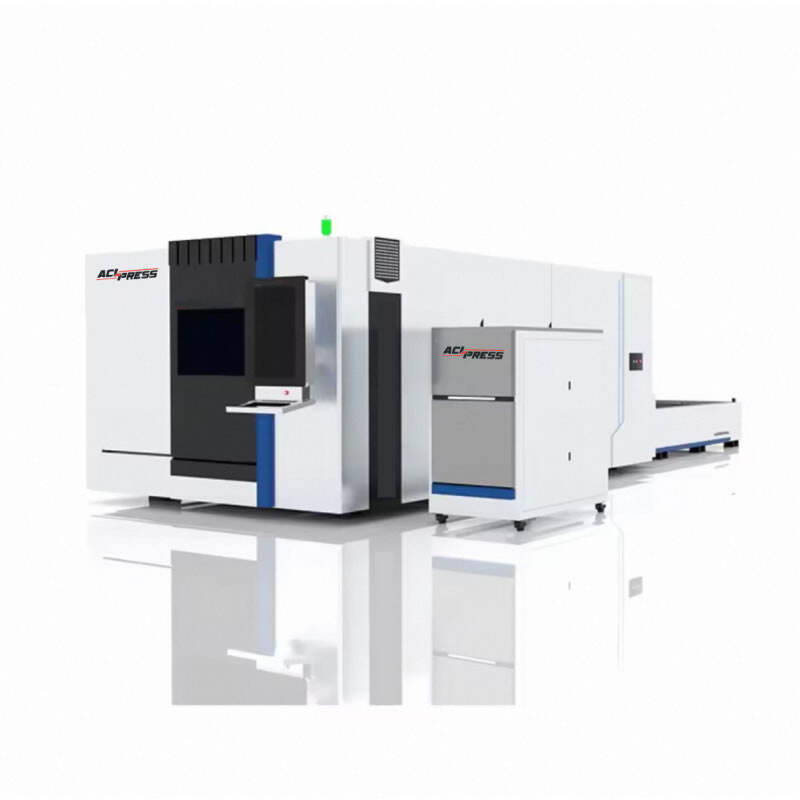

ACLPRESS possesses exceptional processing and the ability to customize products. It is proficient in the specifics of the stamping and pressing that allows it to offer customers optimal solutions built on production drawings or specifications as well as actual conditions to help them achieve meeting their goals in business.

ACLPRESS boasts a robust production capacity includes numerous CNC machine tools including a CNC Gantry machining centre CNC 4 axis machining centers and CNC precise grinding machines. Additionally it a heat treatment workshop to handle various spare parts swiftly and precisely. It also houses a stamping and pressing center makes sure orders from customers are processed in time and accurately.

ACLPRESS possesses not only the most extensive selection of precision equipment for processing presses but also numerous precision inspecting tools to spot product issues, ensuring stamping and pressing and stability. In addition, we provide comprehensive service after-sales.

stamping and pressing is actively involved in the steel bending business since more than 20 years. With a wealth of sales and production experience, we can aid clients in addressing issues across a wide range of products. Our dedicated technical team provides 24/7 technical support to ensure timely and efficient service delivery.