As most people working in metal fabrication will know, press brake are essential devices. The people who do this to metal with the tools they used are called metalworking and fabricating, which I read about, like you would need to bend metal for your project into a machine part, or to make a metal sculpture, but you have a needle which will help you to make this project, If I can to help you blow metal very good. ACL is a good-quality press brake die manufacturer that you can rely on to accomplish the task.

To get the right press brake die for your project, you should choose wisely when it comes to metal work. You need different dies from those if you're doing a different kind of metal, or different shapes you would want to make. If you end up with the wrong die, it can cause damage to your metal or even potentially misshape it completely. But this will not only waste your time but also money, and that's-Not what you are looking for! Fortunately, there are a variety of dies available from ACL to help you find the one that suits you.

There are two different materials used when constructing press brake dies — steel or carbide. Steel dies can be cheaper and make sense depending on the project. Carbide dies, on the other hand, are way stronger and last a lot longer, which often doesnt matter, but if you have a job that requires a lot of bending theyll pay off big time. If you keep casting the same die multiple times, it can wear out early. Well, investing in carbide dies may be a good option. This way, you don’t need to replace them as often, so you can spend your time working instead. ACL provides both types of dies, so you can select the one that suits your requirements.

Press brake dies are one of those excitingists because There are tons of different shapes and designs to choose from. This means you don’t have to be confined to one choice! You can even create custom dies for your own project or design. This alteration allows you to mold metal into any form you desire, be it a slight arc or an intricate pattern. ACL carries dies of all one-of-a-kind shapes and designs, so you are sure to find precisely what you are looking for to complete your metalworking projects.

It is very important for us to be able to take good care of your press brake dies so you make the most of them. You should clean them after every use to maintain their good condition. They should also be stored in a dry space to avoid rusting and damage. Besides, the dies should be inspected frequently for signs of wear and tear, such as chipping or cracking. If you see any errors, then it will be better to change them instantly otherwise you would face a lot of issues while doing your work. ACL can assist you with any care or repair needs, ensuring that your tools are in working order.

If your press brake dies are high quality, you will save money and time down the track. So high-quality dies are made to last longer and give better performance than low-grade dies. And that means you will need to replace them less frequently, and you can have confidence that they will produce the shapes you want every time you use them. While there are several reasons why metalworking businesses trust ACL, one of the leading ones is that ACL produces a variety of press brake dies that are durable and efficient.

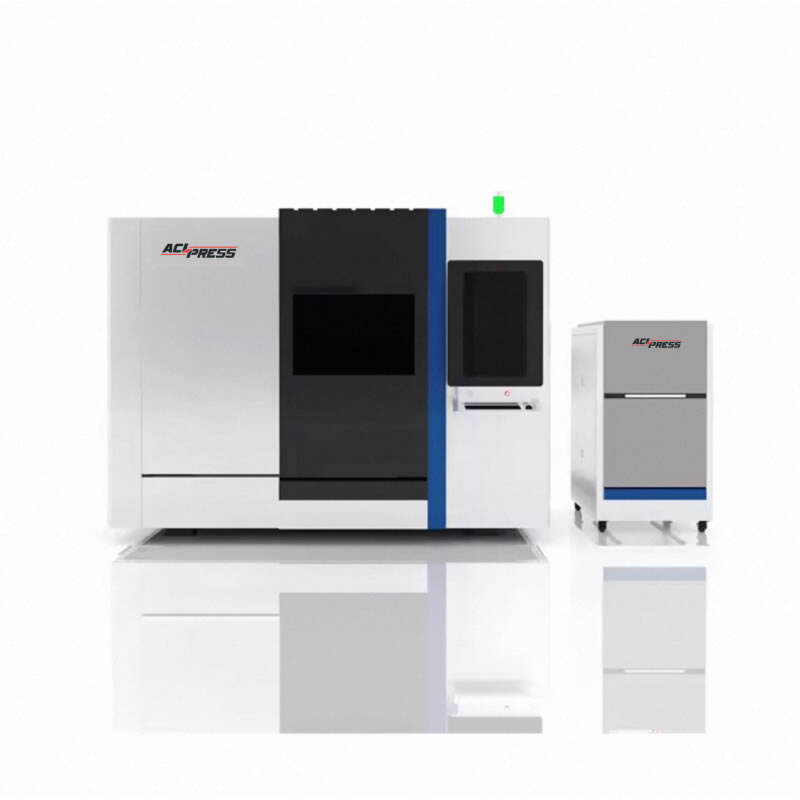

ACLPRESS is not just home to the press brake dies of precision equipment for the processing of press brakes but also various precision inspecting tools to spot defects in the product, and ensure reliability and stability. We also offer a comprehensive after-sales support.

ACLPRESS boasts a robust production capacity includes numerous CNC machine tools including a CNC Gantry machining centre CNC 4 axis machining centers and CNC precise grinding machines. Additionally it a heat treatment workshop to handle various spare parts swiftly and precisely. It also houses a press brake dies center makes sure orders from customers are processed in time and accurately.

ACLPRESS is an expert for processing and customizing products. ACLPRESS is very familiar with the specifics of sheet-metal bent, which allows it to provide customers with optimal solutions press brake dies on their production drawings demands, requirements, and other specifications.

ACLPRESS is press brake dies involved in the steel metal bending industry for more than 20 years. With a wealth of sales and production expertise, we are able to assist customers in addressing and resolving issues across a wide range of products. Our technical staff is available all-hours technical support to ensure prompt and efficient service delivery.