Brake press dies are used in a special tool, referred to as a brake press, designed to bend the metal sheets into shapes. The system begins with a flat metal sheet set on the die. Next, a hydraulic press over a brake press comes down hard on to the metal. It creates a bend or fold in the metal, modifying its shape. The die is quite an important component in this operation because it determines precisely what shape and what angle the bend will take. There are several types of dies; each type can be used for different shapes and bending requirements.

When it comes to selecting press brake, it is best to give a second thought to a few factors. Four, how thick, and what strength is the metal sheet. Metals of different thickness may require different types of dies. Angle of the die, as well as its width and height must also be considered. Choosing the correct die is crucial, as it will help with providing metal bending accuracy and simplicity. The right die lines up with the exact shape you want to receive, which is important for any project.

Be sure to care for your brake press dies well, and they should last a long time. Regular maintenance is key. Make sure you keep the dies clean and dirt free. This prevents any damage when you are using them You should also oil the moving parts of the dies to ensure that they continue to function properly. You'll also want to check for wear and tear — if anything looks damaged, it’s best to repair it as soon as possible. Finally, storage is key, of course. Be sure to put the dies away, so they will not get broken or lost. If you follow these steps your dies should last you much longer.

Custom brake press dies are custom-made for special needs which are actually not able to met by regular dies. Occasionally, particular jobs need certain sizes, shapes, or angles that standard sizes can't supply. Custom dies can be cut to exactly what you need, which may prove useful for your project. The best thing you could do is to purchase high quality custom dies because this will help make your process smoother and it will save you time as well as energy. This makes you more efficient, which is always a good thing.

Brake press dies can be prone to certain mistakes which may cause issues. The biggest mistake is using too much pressure when you push down on the metal. It can also result in material loss due to crushing and abrasion of the bent metal sheet and the die. Just be sure to follow the manufacturer’s instructions closely. it is also important to apply the right die for the bending angle desired. There are also other errors like failing to align the die and metal sheet on the same plane or bending in the wrong plane. If not, the dies may cause you problems as well. Being aware of these common mistakes helps the user in getting better results while dealing with brake press dies.

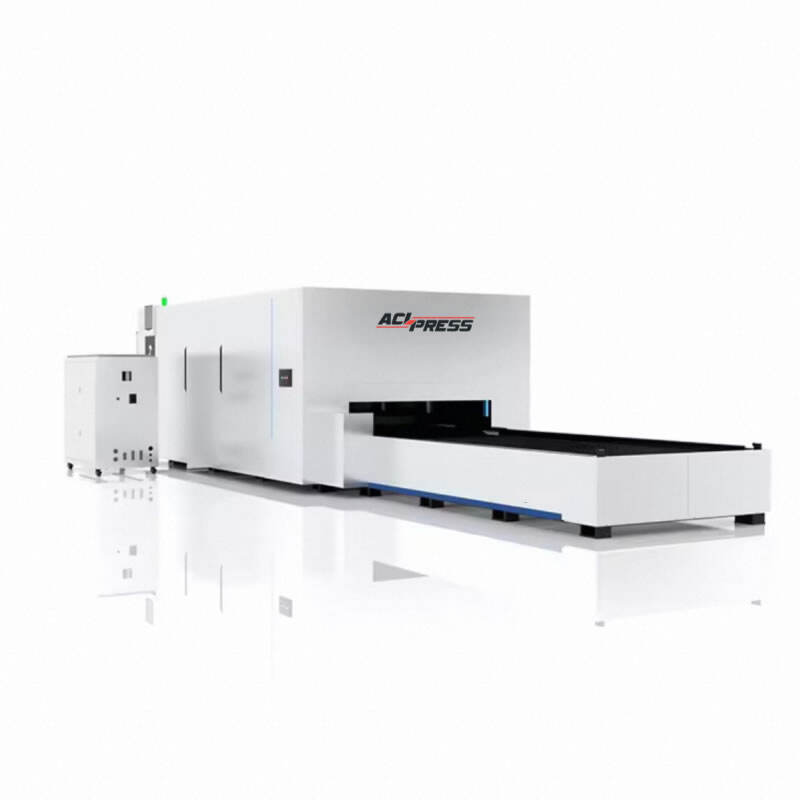

ACLPRESS boasts a large production capacity with numerous CNC machine tools including a CNC Gantry machining center CNC four-axis machining centers and CNC precise grinding machines. Additionally it a brake press dies workshop to treat various spare parts quickly and accurately. Furthermore it houses a debugging centre is specifically designed to ensure fulfillment of orders from customers and the precise fulfillment of their requirements.

brake press dies is actively involved in the steel bending business since more than 20 years. With a wealth of sales and production experience, we can aid clients in addressing issues across a wide range of products. Our dedicated technical team provides 24/7 technical support to ensure timely and efficient service delivery.

ACLPRESS has a large range of high-precision equipment that can process brake press dies, as well with a range of inspection tools that find problems with the product and ensure its reliability. Additionally, we offer comprehensive after-sales support.

ACLPRESS is a leader for processing and customizing products. It is proficient in the specifics of the bending of sheet metal and can offer customers the most efficient solutions, built on production drawings as well as requirements and conditions to assist them in reaching their brake press dies.