One important tool in the manufacturing process is the press brake. They help mold metal into the ideal shape to manufacture products. Press break dies are vital to making sure that the products we use every day are made well and work right—even if most people never see them. This article will cover the importance of having a properly designed press brake die, how press brake dies operate, how to select the right press brake die for your application, the benefits of using a high-quality press brake die, and how a quality press brake die can enhance your manufacturing process. As a manufacturing solution provider, we know well at ACL that there is a compelling need for high-quality press break dies.

It is the press break die that shapes the metal. They are used to make bends and angles needed in the finished product. High precision press break die is very important, no matter how expensive your press break machine is, the bends of the metal that you have are accurate or not will decide the quality of the metal product that you have. This can lead to badly manufactured products if the die is of bad quality. Which can waste time and money leading to costly mistakes that must then be corrected. The use of quality press break dies can boost the production process as well. The work can therefore be completed faster and more seamlessly, resulting in superior products and reduced downtime.

The press break die's first role is to develop the necessary angles and shapes of the metal. Therefore choosing the right press break die based on the material of the metal is very crucial. Press break dies come in a variety of sizes, shapes, thicknesses and materials. Selecting the best press break die for your project can greatly impact the quality of your finished work. ACL holds variety of press break dies that cater to metalworking needs. This means that you are bound to find a tool that fits your job.

Selecting the appropriate press break die is of utmost importance in creating quality products and maximizing production times. It can also save the construction materials and lower the overall construction cost, especially when you find a suitable die. By and large, there are a few factors you want to consider when selecting a press break pass on. Such as you should consider about how thick the material is or what sort of metal you might be doing. Furthermore, the final shape and angle of the part must be taken into consideration to identify the most suitable type of press break die that should be used. Our experts at ACL will help you determine the correct press break die depending on your manufacturing requirements. We want you to receive the best possible results.

Benefits of investing in a high-performance and high-quality press break die. The major advantage is that with these dies, the accuracy of the shaping is quite high, so the product quality is the best. They can also reduce production times that therefore make the whole process more efficient. In addition to that, high-performance dies ensure safety in the workplace. Also, they can make thinner shapes, and they usually don't break as easily as their low-quality counterparts, which is extremely difficult to find. They are in the well-suited material of CNC-ground tool steel and hardened tooling steel, suitable for enduring constraint for a long time. They are also tough, so you can expect accurate and consistent results for decades to come. Founded in Tokyo, Japan, ACL manufactures high-Performance press break dies to enable you to extract the utmost from your own manufacture process.

The use of the correctly designed press break die significantly enhances the production process along with the correct tooling. An accurate and well-engineered press break die can not only speed up the entire production line but also maximize your profits and product quality. Giving workers the right tools and knowledge to do the job not only enables them to get the perfect result but allows them to do so whilst taking care of other crucial responsibilities. This not only increases production but assisting in a more effective working surrounding.

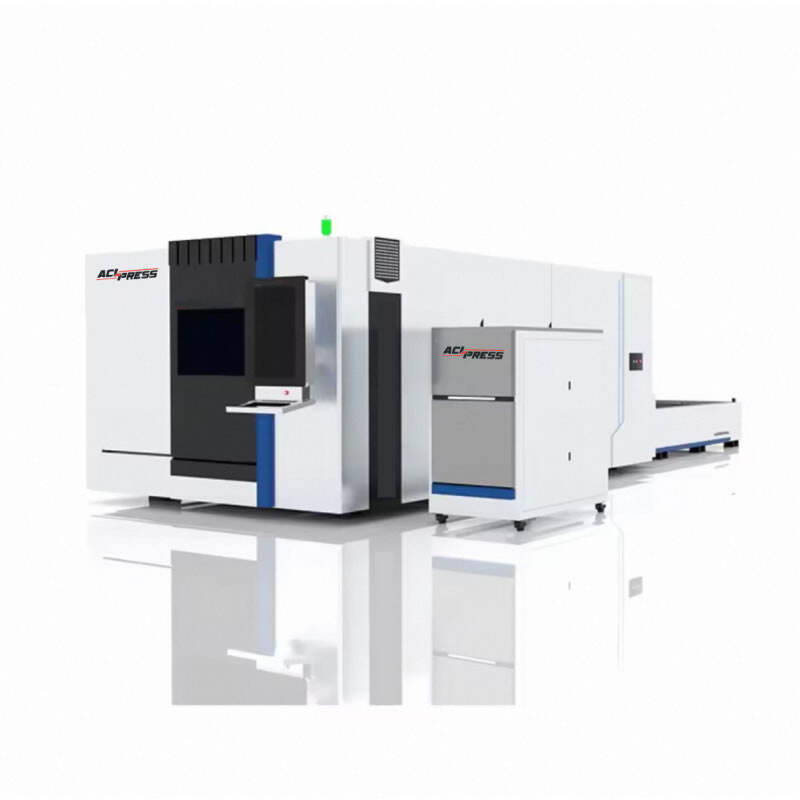

ACLPRESS has a large range of high-precision equipment that can process press brakes, as as a variety of inspection tools that detect problems in the product and assure its durability. Furthermore, we provide an extensive press break die.

ACLPRESS press break die exceptional processing and capability to customise products. It is well-versed in the specifics of the bending of sheet metal which allows it to provide customers optimal solutions built on production drawings specifications, needs, and current conditions to help them achieve meeting their goals in business.

ACLPRESS a substantial production capacity due to its press break die which include a CNC gantry machine CNC 4-axis machines and CNC precision grinders. Additionally it a heat treatment workshop which handles various spare parts efficiently and accurately. The facility also houses a debugging centre ensures orders placed by customers are delivered on time and precisely.

ACLPRESS is actively involved in the steel bending business for more than 20 years. With extensive production and sales knowledge, we can help clients in addressing issues in a broad range of product applications. Our press break die provides round-the-clock technical assistance, 24 hours a day providing prompt and top-quality service to our customers.