Today we will be learning all about a special machine, called a brake press. Brake press machine are employed in many industries to dig metal in various products. These are powerful machines that must be operated in a manner that is safe for all involved.

The working of a ACL tools press brake is done via the hydraulic system. This pump applies pressure to a metal strip to form or shape it into the desired shape. They are commonly used to create metal parts in manufacturing, construction, and also in the process of car making. They are the ones that help make everything from simple brackets to complicated pieces of machines.

Safety Rules While Using press brake bending Wear protective equipment such as gloves and goggles to protect yourself. But before you bend that metal, make sure you have the metal piece in the correct location. Note the pressure and speed settings on the machine so you get the correct bend without damaging the metal.

Because you have to follow strict safety rules when you use a brake bending tool at work. To ensure everyone's safety, the machine must be used only by trained individuals rather than by the public. Additionally, the machine should regularly check the machine, and take care of it. Accidentally making the space untidy when working leads to either slips or falls.

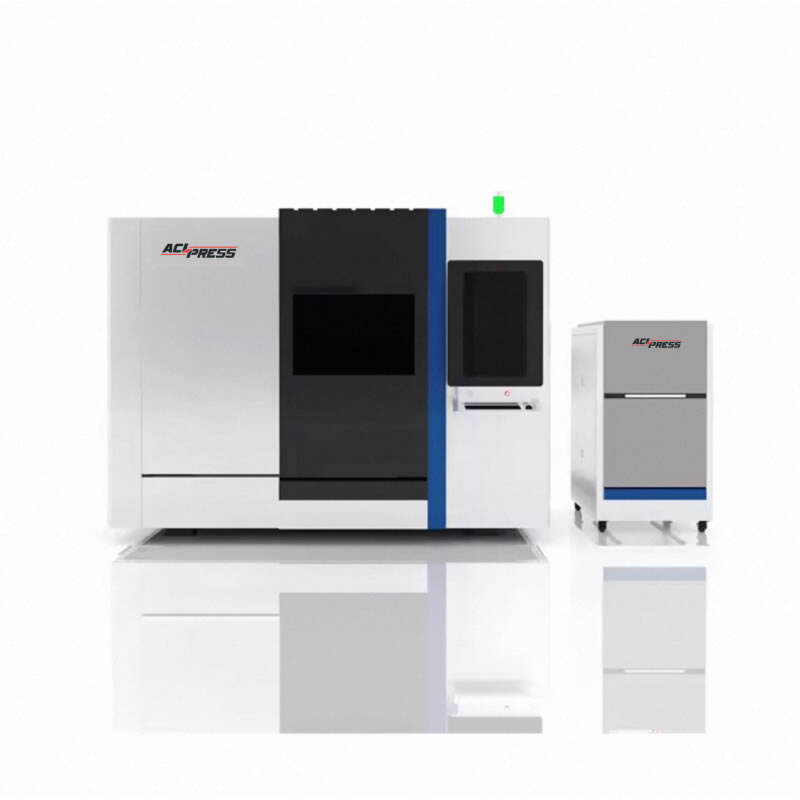

Consider the size of the metal parts you will be bending, the thickness of the metal and how precise you want to be when choosing a brake press machine. ACL has several press types with different capabilities available to suit your needs. Consult our specialists to choose the right machine for your needs.

Over the years, brake press machines have evolved with new features and technology. New machines have computerized controls for more precise bending and shaping of metal. Some machines include automated tool changers and robotic arms to help them work more quickly. ACL is constantly innovating press brake tool for our customers to have the best tools for the job.

ACLPRESS boasts a significant production capacity due to its CNC machines like a CNC Gantry Machine CNC 4-axis machines and CNC precision grinders It also operates the heat treatment workshop which can process various spare parts fast and precisely In addition it houses a debugging centre that is specifically designed to ensure prompt completion of customer orders and the Brake press machine of their needs

ACLPRESS possesses exceptional processing and the ability to customize products. It is proficient in the specifics of the Brake press machine that allows it to offer customers optimal solutions built on production drawings or specifications as well as actual conditions to help them achieve meeting their goals in business.

ACLPRESS has been actively involved in the Brake press machine industry for more than 20 years. We have a wealth of experience in sales and production, and can help customers address and resolve problems for a variety of product applications. Our dedicated technical team provides all-hours technical support to ensure speedy and quality service delivery.

ACLPRESS offers not just the most extensive selection of precision equipment for the processing of press brakes but also numerous precision inspecting tools to spot issues with products, Brake press machine durability and reliability. In addition, we provide comprehensive after-sales service.