Have you ever wondered how toy cars or even your bicycle is made? The above items are made with tools and machines! Machines are heavily involved in how we create a large portion of the things we utilize every day. They guide us in making products that are fun, useful, and in some cases essential to our lives.

Since ancient time machines have been used. The earliest machines date all the way back to the 1700s! These early machines were very rudimentary. It could only transform into simple shapes, and was not particularly powerful. But even these are simple machines that I started the process of making easier and faster.

Eventually, people learned increasingly about improving machines. They discovered ways to improve them, to make them stronger and more useful. They made tools that could work faster and be more accurate by applying electricity and new machine tools. This meant that they were able to create visually matching parts that mated well.

Big difference is making products fuller time. Efficiency is making things fast and pedestrian. That's efficiency—it's like the superhero of getting shit done! With machine assistance, factories can produce more products in less time. This is vital because it assists in getting products to individuals as and when needed.

Robots are a special type of machines that can perform numbers of tasks. They do tasks such as welding, which is the process of joining metal parts together, and painting objects with accuracy. Robots are also very useful for dangerous work for people to do, such as working with bad chemicals or heavy things. With robots, factories can protect workers and get work done.

For instance, some machines can produce airliner components in a fraction of the time and with remarkable precision. This matters, because airplane parts must fit together precisely to be safe. Though there are machines capable of cutting and shaping metal and wood with extreme accuracy. Working with wood or metal, these machines help blossom in beautiful furniture or worn building material.

Factories can produce highly accurate products that function well with the aid of machines. For example, they can create the engine of a freshwater vehicle to work with smoothness and optimal performance. It means cars can drive better while using less fuel. They can also build medical devices that are safe and accurate — a must for aiding doctors and patients.

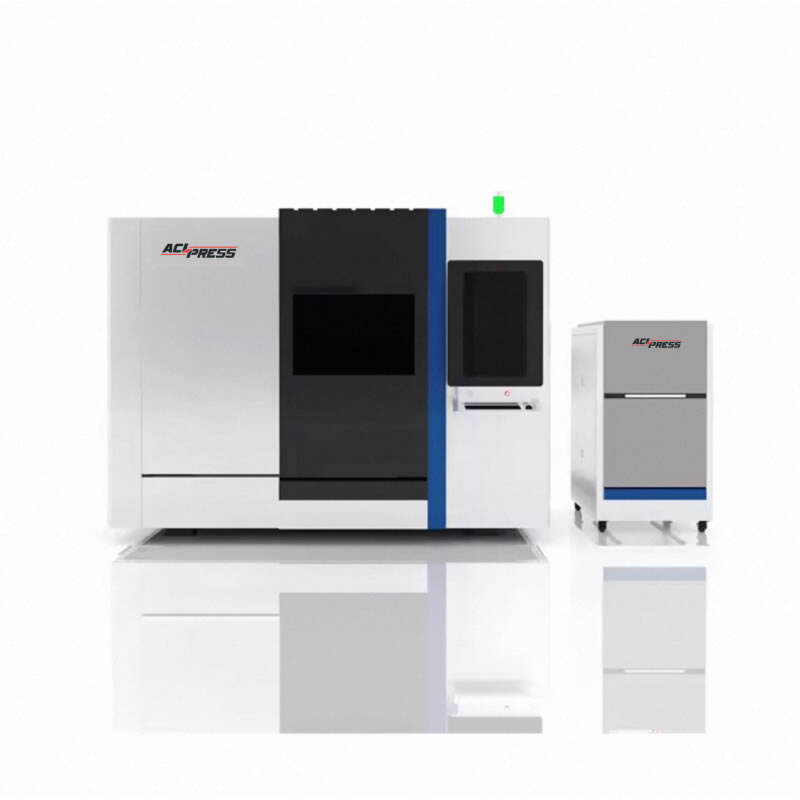

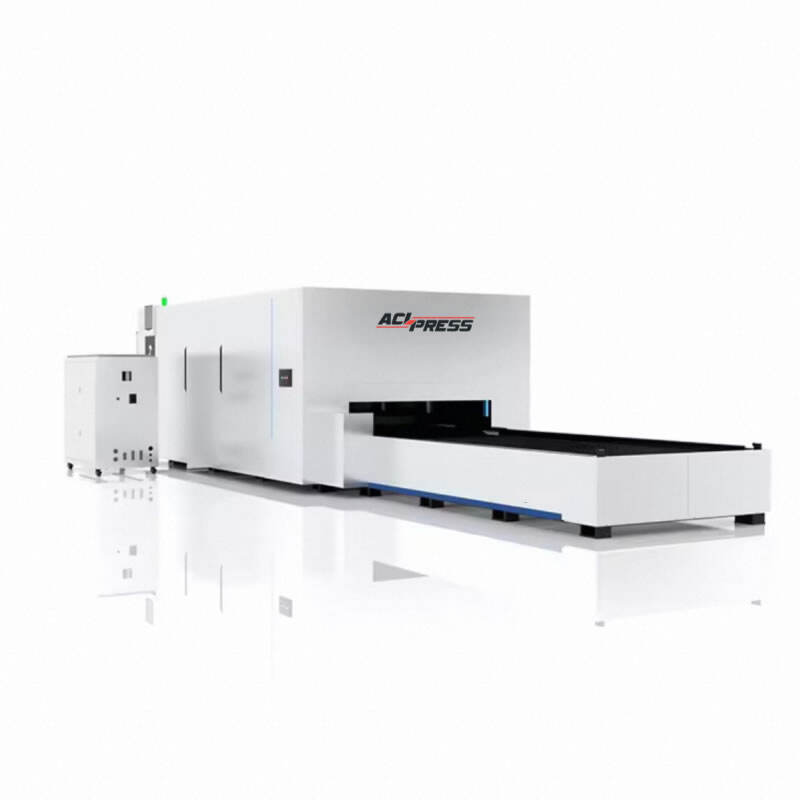

ACLPRESS machine and machine tools a broad range of precision equipment to process press brakes, as as a variety of inspection tools to detect problems with the product, and help ensure its dependability. Furthermore, we provide an extensive service after-sales.

ACLPRESS is actively involved in the field of steel bending for over 20 years. With machine and machine tools and sales knowledge, we can help our customers in resolving problems in a range of applications for our products. Furthermore, our technical staff provides 24/7 technical support, seven days a week, ensuring prompt and high-quality support to our customers.

ACLPRESS has an exceptional capability in the processing of products and modifying them. It is machine and machine tools in the particulars of the sheet metal bending sector, enabling it to offer customers the most efficient solutions, based on production drawings or specifications as well as actual circumstances to help them in meeting their goals in business.

ACLPRESS boasts a large production capacity with numerous CNC machine tools including a CNC Gantry machining center CNC four-axis machining centers and CNC precise grinding machines. Additionally it a machine and machine tools workshop to treat various spare parts quickly and accurately. Furthermore it houses a debugging centre is specifically designed to ensure fulfillment of orders from customers and the precise fulfillment of their requirements.