ACL Collider Best sheet metal bending dies manufacturer. These machines are critical for machining metal with high precision. That means they can cut precisely, even through thick pieces of metal. These machines are also powered with advanced technology that helps them perform functions that are usually not possible with other machines. Therefore, they are increasing their representation in many metal working sectors.

In laser cutting machines laser beam strikes the metal with lots of power. A super intense laser beam sliced through steel in very little time and with precision. These machines are incredibly efficient because of this speed and accuracy. This saves businesses considerable time and costs if they require cutting metal for their products. While etching with conventional methods can take hours and even days, laser machines can complete work in a fraction of the time.

The best example of how press brakes are revolutionizing metal product manufacturing worldwide. Cutting of metal was a challenge for a long time and in accurately makes a metal products was a long process. But in these days of magical laser machines metal gets cut quickly and precisely. This allows metal items to be produced at a significantly faster rate and under a more budget-friendly cost, both of which encourage business growth and development.

The metal laser cutting machines are one of the fastest machines. They can slice metal in a fraction of the time as with other species of engines. Such speedy productivity allows businesses to create more products per unit of time, which can drive higher profit margins. The cuts using laser machines are very clean as well, in addition to being quick. Laser cut thick metal without causing rough edges or any type of defect. This results in much higher quality metal products as compared to traditional machines.

Laser technology is quite adaptable, capable of cutting various metals. It is fully capable of slicing through stainless steel, aluminum, copper, brass, and so on. This diversity is granted because companies can generate diverse metal products to suit differential needs. For example, a company that needs to make parts for cars, tooling, or make artwork can all be done with laser machines.

Laser devices are as well extremely precise. Many industries require this precision, and aerospace is one of the most crucial. Aerospace manufacturers require highly precise parts for their airplanes and rockets, because even the smallest deviation can cause major issues. These machines are used to mill these parts very precisely, so they are the ideal choice for this critical field.

Metal laser cutting machines will only get better as laser technology continuously improves. Metal 3D printing: Paving the way for newer designs and fabrication possibilities That means that chainmail will be able to take even more complex shapes and designs that are now not possible. Metal laser cutting machines are already changing the way we design our metal pieces, and in the future they will have an even greater impact on the industry.

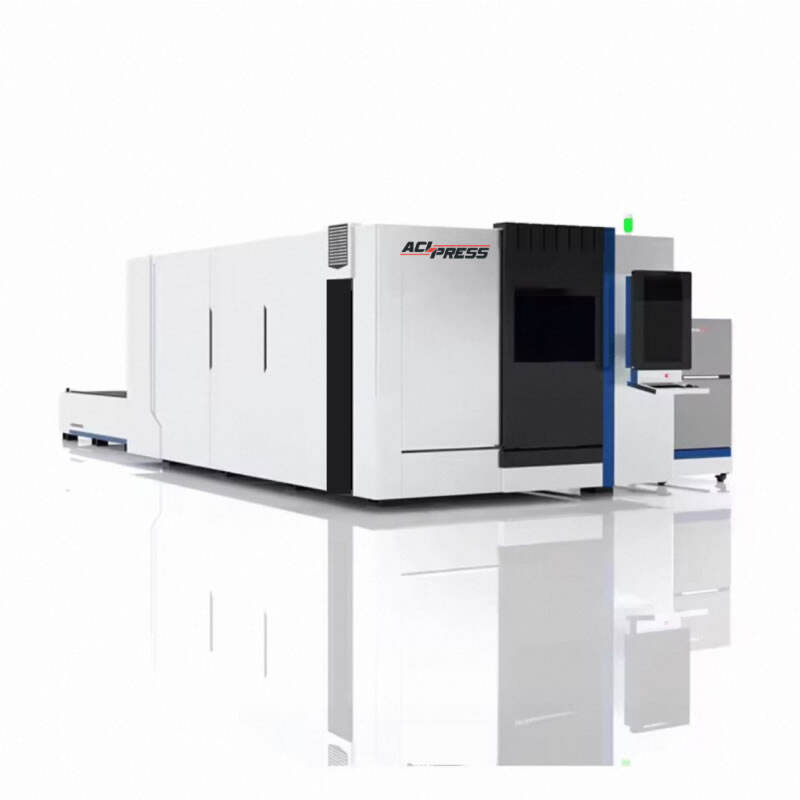

ACLPRESS boasts a significant production capacity due to its CNC machines like a CNC Gantry Machine CNC 4-axis machines and CNC precision grinders It also operates the heat treatment workshop which can process metal laser cutting machine fast and precisely In addition it houses a debugging centre is specifically designed to ensure prompt completion of customer orders and the exact fulfillment of their needs.

ACLPRESS is actively involved in the field of steel bending for over 20 years. With metal laser cutting machine and sales knowledge, we can help our customers in resolving problems in a range of applications for our products. Furthermore, our technical staff provides 24/7 technical support, seven days a week, ensuring prompt and high-quality support to our customers.

ACLPRESS is an expert for processing and customizing products. ACLPRESS is very familiar with the specifics of sheet-metal bent, which allows it to provide customers with optimal solutions metal laser cutting machine on their production drawings demands, requirements, and other specifications.

ACLPRESS offers not just the most extensive selection of precision equipment for the processing of press brakes but also numerous precision inspecting tools to spot issues with products, metal laser cutting machine durability and reliability. In addition, we provide comprehensive after-sales service.