Factory press brake are like special shapes for metals that are flat which are changed into different shapes. These tools are actually super important as they are used to create many types of products that we use on a daily basis. At ACL, we recognize how essential these bending dies are to manufacturing. This is why we also strive to develop products that are solid, reliable, and our customers can depend upon. We want to enable companies to produce precisely the products they desire with our superior bending dies.

They are used to bend sheet metal, in a predetermined direction or angle to give the sheet metal the desired shape. Bending is also referred to as forming. A bending die consists of two main components: the punch and the die block. To begin, the flat slab of metal goes between these two parts. Then pressure is exerted to form the metal into the configuration we desire.

The punch has a custom-shaped end and is made of extremely hard steel. This end is shaped to be the form we want the metal to take. On the contrary, the die block is also formed of hard steel which has a space or cavity coinciding to the shape of the punch. Under pressure, the metal flows into this cavity, which forms the intended shape. Imagine making cookies with a cookie cutter; the punch cuts the metal in the correct shape!

Not only are they efficient, but bending dies offer manufacturers the ability to form a vast range of shapes and sizes. This flexibility is crucial for a wide range of sectors that need bespoke metal solutions. For instance, an automotive manufacturer requires unique components to be manufactured in very snug tolerances, bending dies doaccomplish that quite very effectively.

One of the great aspects about sheet metal bending dies is the wide variety of shapes and sizes that they come in. This makes them applicable in a diverse range of applications. When some simple shapes are required, such as a straight bend, some bending die are devised, for more complex ones that require multiple bends — another type of die is employed. Automotive, aerospace, electronics and construction sectors are some of the industries that utilize these tools.

Bending dies can create a range of products, from brackets and clips to frames and supports; this versatility means they're used in aerospace, construction, automotive, and many other industries. This versatility has enabled them to become an integral component for manufacturing industries where both accuracy and speedy production are essential to success.

Here are a few things to consider when selecting sheet metal bending dies for your production. Type of Reinforcing Material When we talk about the opposite which is the separate types, you will just need to consider the material that the separate type must have. In addition, the thickness of the sheet metal is also important as thicker sheets would require larger pressure to bend properly. There is also a need to consider the bending angle so that the final product has specifications that are acceptable.

ACLPRESS is sheet metal bending dies involved in the steel metal bending industry for more than 20 years. With a wealth of sales and production expertise, we are able to assist customers in addressing and resolving issues across a wide range of products. Our technical staff is available all-hours technical support to ensure prompt and efficient service delivery.

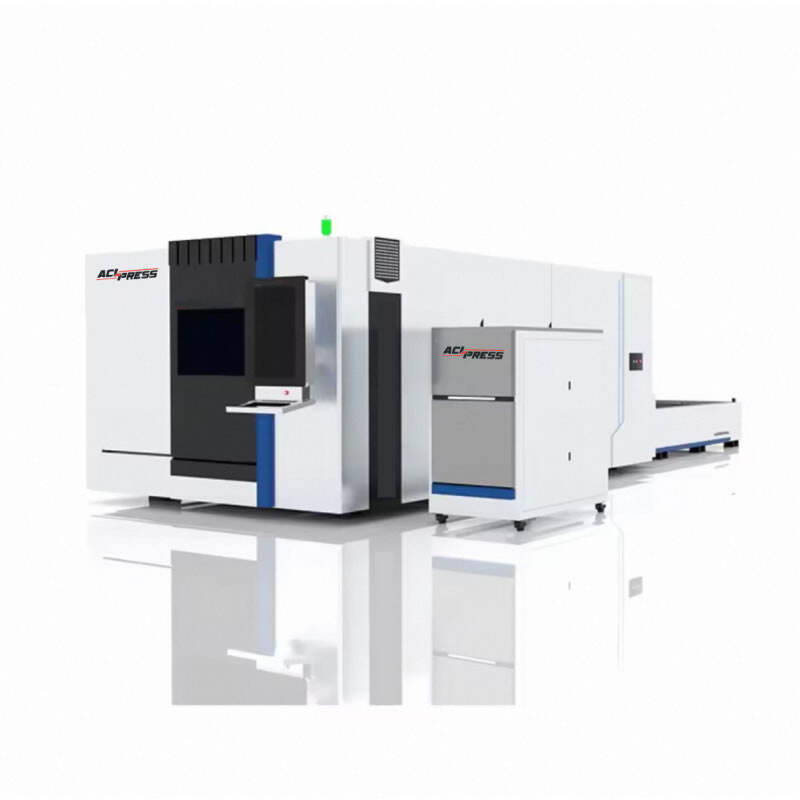

ACLPRESS offers a wide range of equipment with precision to process press brakes as well as a variety of inspection tools that can sheet metal bending dies in the product and assure its dependability. We also provide a full after-sales service.

ACLPRESS has an exceptional capability in the processing of products and modifying them. It is sheet metal bending dies in the particulars of the sheet metal bending sector, enabling it to offer customers the most efficient solutions, based on production drawings or specifications as well as actual circumstances to help them in meeting their goals in business.

ACLPRESS boasts a large production capacity with numerous CNC machine tools including a CNC Gantry machining center CNC four-axis machining centers and CNC precise grinding machines. Additionally it a sheet metal bending dies workshop to treat various spare parts quickly and accurately. Furthermore it houses a debugging centre is specifically designed to ensure fulfillment of orders from customers and the precise fulfillment of their requirements.