Shearing Sheep is a Job is a Kids Book about the very important job helping keep the sheep comfortable and healthy. Shearing sheep removes their wool and helps them keep cool and clean. Shearing sheep by hand was once the way to go. This was a huge work that required a lot of time and effort. Farmers had to do it very carefully. They would use scissors or hand shears, so the job was slow and sometimes difficult. Now, with a new machine, sheep can be shorn much faster and much, much easier. Today, we find out why more farmers and ranchers are adding hydraulic press brake machine to their operations.

In the years since, sheep shearing machines have gained tremendous popularity. This is primarily because they enable the work to be done faster and easier. So these machines shear a whole lot of sheep at once, which is useful to farmers who may have many sheep to shear. Machines can shear several sheep in a matter of minutes, instead of spending hours working on one. Well, this means farmers would take very quickly to complete their work and can shift their focus on some other main work in their farms. Due to these benefits, machine shearing is the most preferred option among farmers who have comparatively larger flocks of sheep.

Machine shearing works much faster, one of its great advantages. When farmers shear sheep by hand, the process can be slow — sometimes taking hours just to shear one sheep. But with a machine, a farmer is able to shear a sheep within a couple of minutes! That enables farmers to shear far more sheep in a shorter time. This is a huge factor in determining how profitable the farm will be, and by cutting down on the labor force needed, it saves a lot of money.

Machine shearing is also a lot more convenient than hand shearing. Shearing is easier and faster with a machine, and does not require as much physical effort. Farmers and ranchers become less tired and can conserve their energy for other essential work on the farm. For instance, making sure that the sheep are cared for after shearing, or feeding them or doing repairs on the farm. Being able to use machines to help them quickly finish shearing gives them more time for those other jobs.

Moreover, press brake is far safer than shearing by hand. It helps protect against injuries to the sheep and to the shearers. Hand shearing sheep can also cause accidental harm to both sheep and farmers themselves. They are safer and efficient, which minimizes the risk of accidents. This is necessary to ensure the safety and health of both the sheep and the people who work with them.

Machine shearing is also a lot more convenient than hand shearing. Using machines is easier and helps save the farmers in energy and time seeking and into the field. With a reduced shear time, farmers are less tired post shearing and are able to carry out other jobs that need to be completed on the farm. It could mean feeding animals, planting crops or repairing fences.

Having machines on hand also saves the sheep from injury. When sheep are sheared by hand, there is a possibility that small cuts or nicks can be made on their skin that is painful and can develop infections. A machine is built to shear sheep more gently and carefully, reducing the likelihood of these types of injuries. This is extremely vital for the sheep’s health and well-being.

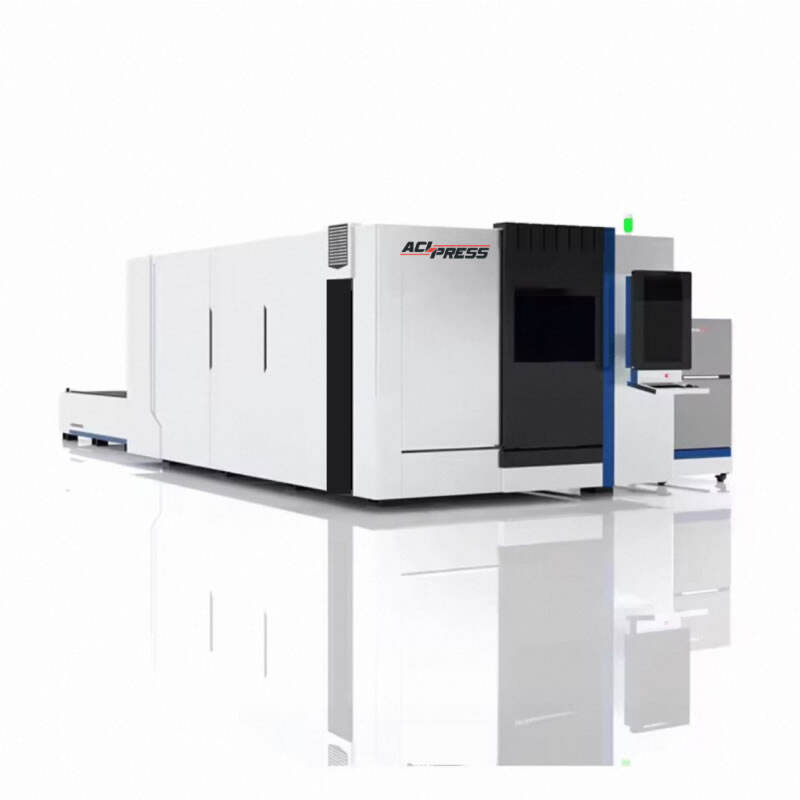

ACLPRESS possesses exceptional processing and the ability to customize products. It is proficient in the specifics of the machine shearing that allows it to offer customers optimal solutions built on production drawings or specifications as well as actual conditions to help them achieve meeting their goals in business.

ACLPRESS boasts a large production capacity with numerous CNC machine tools including a CNC Gantry machining center CNC four-axis machining centers and CNC precise grinding machines. Additionally it a machine shearing workshop to treat various spare parts quickly and accurately. Furthermore it houses a debugging centre is specifically designed to ensure fulfillment of orders from customers and the precise fulfillment of their requirements.

ACLPRESS is not just home to the machine shearing of precision equipment for the processing of press brakes but also various precision inspecting tools to spot defects in the product, and ensure reliability and stability. We also offer a comprehensive after-sales support.

ACLPRESS is actively involved in the steel bending business for more than 20 years. With extensive production and sales knowledge, we can help clients in addressing issues in a broad range of product applications. Our machine shearing provides round-the-clock technical assistance, 24 hours a day providing prompt and top-quality service to our customers.