Machine design is an exciting experience where we create and design tools to aid our work so that we can accomplish our daily jobs faster and more efficiently. Today, machines are plenty of in lots of fields from agriculture to construction, manufacturing, and so on. Farmers use machines to plant and harvest, builders use machines to lift heavy materials, and factories use machines to create products faster. The individuals who stock these machines put considerable effort into ensuring their creations function as intended. This article will provide insights on how machines are designed and what distinguishes an effective, useful machine design from others.

Machine design has also very important safety aspect. Designers have a responsibility to make sure that the machines they design for people to use actually do not hurt the environment. For instance, they may consider literally how to create a machine that minimizes waste or uses energy sustainably. Coverage should be designed to work well, AND with a price point, AND it must fit the process.

Designers simply have to be creative innovative. They have to tread the cutting edge of technology in the quest for machines that are ever faster, lighter, more efficient. Advancements in new technologies such as AI and IoT can help enhance the design of machines significantly. AI, for example, is able to enable machines to learn from their experiences and IoT allows machines to communicate between each other and share data in real-time.

The purpose of a machine design is also important. Machines should do what they are supposed to do: reliably and efficiently! So the design has to represent what the machine is there for while making sure that it is safe and easy to use. Finding an ideal balance between them can prove to be quite challenging, but through adequate research and experimentation, designers can make machines that are attractive yet also functional.

There are always designer searching for better way of machine design to produce and design new and better products. The machine design landscape: What are the emerging technologies? Designers are eager to apply these new tools to their work, to make machines smarter and more efficient, and to help them connect better to their environment.

Machine design is heavily dependant on automation. >It looks very easy, but behind this scenario, designers are designing such automation systems that can make industries more effective and productive. Automation machines enable workers to do tasks faster, and cheaper. They also minimize the risk of human error, making them more trustworthy for complicated jobs.

Designing machines is a specialisation that requires a cocktail of expertise, creativity, and out-of-the-box thinking. In the field of machine design, we want our machines to be safe, simple, and practical. Designers have to take notice of what users are requiring, and at the same time, applying new technologies themselves to enhance their designs.

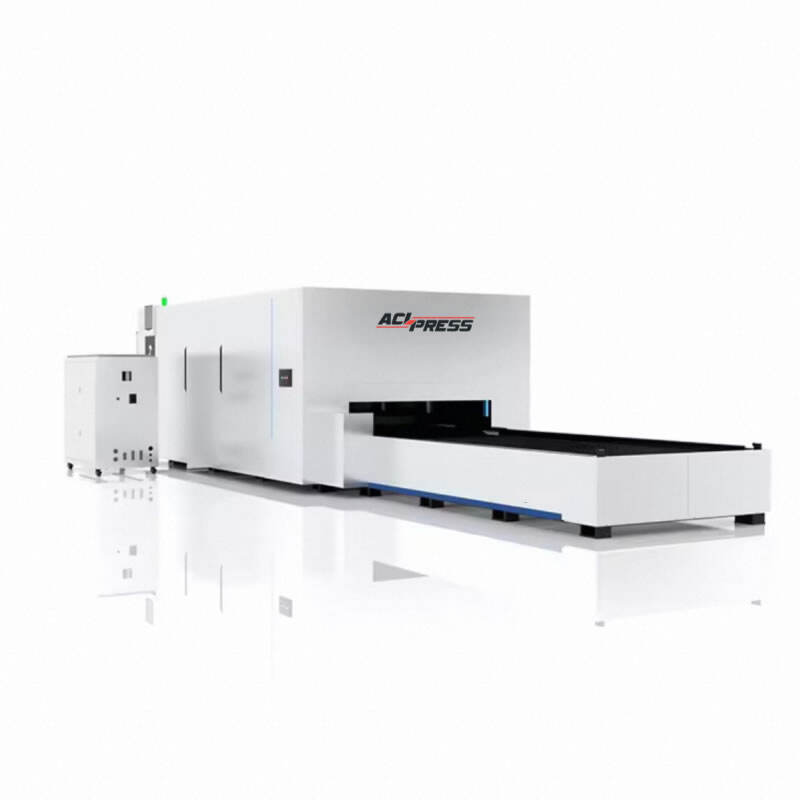

ACLPRESS is actively involved in the steel metal bending industry for more than designing machines. With a wealth of sales and production experience, we can aid customers with resolving problems across a variety of product applications. Our team of experts provides 24 hours of technical assistance to ensure quick and high quality service delivery.

ACLPRESS possesses designing machines and the ability to customize products. ACLPRESS is well-versed in the specifics of sheet-metal bending, allowing it to provide customers with the best solutions built around their production drawings demands, requirements, and other specifications.

ACLPRESS offers not just the most extensive selection of precision equipment for the processing of press brakes but also numerous precision inspecting tools to spot issues with products, designing machines durability and reliability. In addition, we provide comprehensive after-sales service.

ACLPRESS designing machines a robust production capacity with numerous CNC machines which include a CNC Gantry machining centre CNC four-axis machining centers and CNC precise grinding machines. It also operates a heat treatment workshop treats various spare parts swiftly and precisely. It also a debugging centre to ensure the orders of customers are fulfilled punctually and accurately.