There are specific tools to help you with this — rolling machines are one of the most important of those that help you shape metal sheets. They work by running a flat piece of metal through two large pins that bend the metal into the desired shape. This method is much simpler than the previous method of shaping metal by hand. Once upon a time, metal could only be bent using hands and brute force, which was both hard and time-consuming. We can also reduce the hard labor we apply to the task using rolling machines.

Rolling Machines vs. Bending Metal by Hand: What You Need to Know So, the main reason: rolling machines save a ton of time. These machines can instead do the job in a fraction of the time than bending it by hand for hours. The second one is that rolling machines can handle thicker metal sheets. Hand bending thicker metal is extremely difficult; rolling machines make things easy. The third advantage is that rolling machines are easier to use. In contrast to manual techniques, which demand a great deal of knowledge and experience, rolling machines are simple to use for any non-specialists. Finally, rolling machines give consistent results every time you use them. This is especially significant in roles where measurements must be accurate, such as in manufacturing plants that produce goods.

There are different kinds of rolling machines that you can buy. Some machines are manual, requiring you to turn a handle by hand to get it going. This one can be awesome for smaller tasks or if someone tends to work manually. Electricity powers other machines, so they do the work on their own with the push of a button. This makes them more efficient for larger tasks, and electric machines often have more output power. There are different sizes of Rolling machines available as well. Some are small and intended for small projects, and others are large and built for large factories that have heavy-duty jobs.

Here are some key aspects you should pay attention to before you buy your rolling machine. First determine exactly what kind of metal you will use. Other types of metal roughing will be better for different machines. Second, how large should the machine be and its capacity? You need to ensure it is suitable for your workspace and ready to handle the standard size of metal sheets you will be using. Third, consider the metal sheets’ thickness. Some are better suited for thin sheets; others can accommodate thicker ones. You should also given a thought about your budget. How much are you ready to pay for a rolling machine? Finally, it’s worth checking out the company that produces the machine. Inspect their reputation and ask them if they provide warranties that protect your purchase.

Regular maintenance is crucial to keep your rolling machine in optimal condition. That means you need to clean the machine regularly to clear out dust and metal shavings. There is also the moving parts and that will need lubrication so that it can work smoothly. Regularly checking the electrical connections is essential to avoid any problems. Replace any worn or broken parts immediately. It’s also important to use the manufacturer’s recommended maintenance schedule. If you maintain your rolling machine properly, you can prevent problems and increase its longevity.

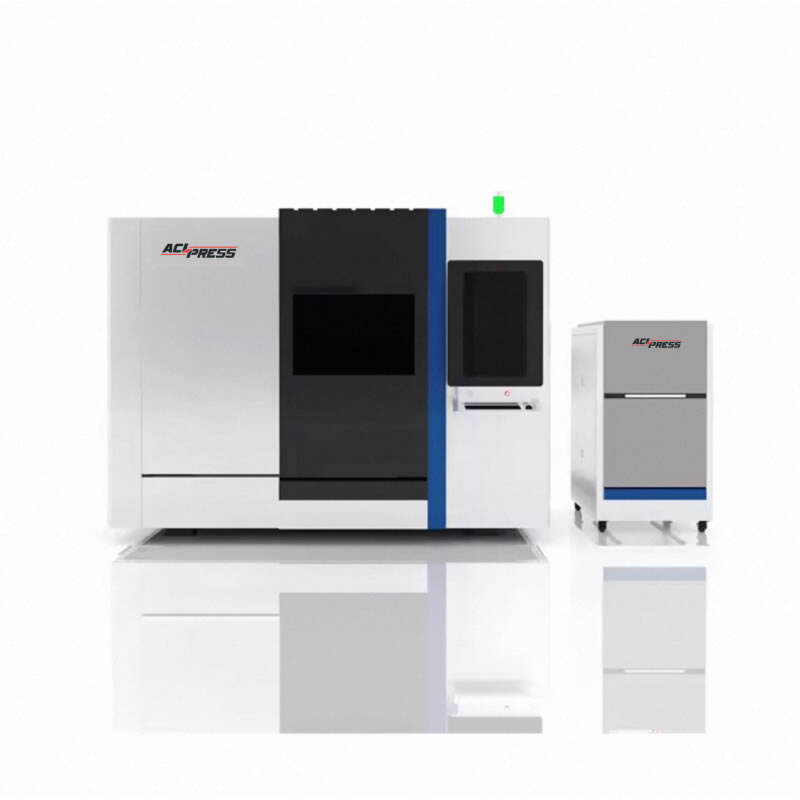

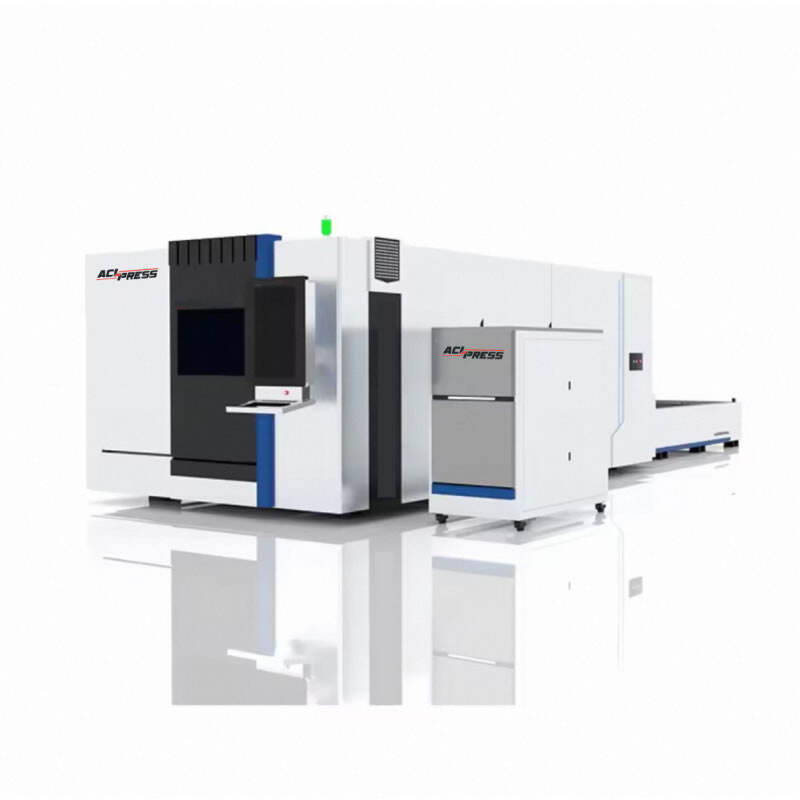

ACLPRESS is an expert for processing and customizing products. ACLPRESS is very familiar with the specifics of sheet-metal bent, which allows it to provide customers with optimal solutions rolling maching on their production drawings demands, requirements, and other specifications.

ACLPRESS boasts a robust production capacity includes numerous CNC machine tools including a CNC Gantry machining centre CNC 4 axis machining centers and CNC precise grinding machines. Additionally it a heat treatment workshop to handle various spare parts swiftly and precisely. It also houses a rolling maching center makes sure orders from customers are processed in time and accurately.

ACLPRESS is not just home to the rolling maching of precision equipment for the processing of press brakes but also various precision inspecting tools to spot defects in the product, and ensure reliability and stability. We also offer a comprehensive after-sales support.

ACLPRESS is involved in the steel bending business for more than 20 years. With a wealth of sales and production experience, we can assist our customers in resolving issues in a rolling maching of application areas. Our technical staff is available all-hours technical support to ensure prompt and top-quality service delivery.