Press machines are one of my favorite machines because they are fun! We have press brakes are special tool which we use to make different things by pressing on material like metal, paper, different types of fabric. We boast making, at ACL, some of the finest press machines available.

So, how does a press machine work? If you want to reshape a material, the first step is to get it between two flat plates. These plates also have lots of strength and help hold the material in place. Then you clamp the plates down with the press machine hard. This creates stress on the material and it begins to be deformed. You can make all sorts of shapes like circles or squares based on your requirements. You see the material and it magically converts to _____!

People often book brake presss who need to create many same items in minimal time. For example, a press machine will allow you to print the same picture or a design on multiple t-shirts. That means you don’t have to do it manually, which would take an age. It saves a lot of time and manual grinding by using a press machine. Unlike creating the t-shirt one at a time, we could print multiple shirts in a fraction of the time! This is fantastic for companies with a lot of items to move.

To benefit the most from your press machine, it’s vital that you get how to set it up properly and use it safely. And be sure to read the instructions when you first use it. This is how you learn how the machine works. Safety is a big part of this, so ensure you have appropriate safety equipment, such as gloves and goggles. The gloves protect your hands, and the goggles protect your eyes from flying bits, which can occur when you press the materials. With these tips you are on your way to having a fun and safe experience!

So like, press machines are used in a lot of different jobs, yeah? They are involved in things such as car manufacturing and food processing. So, as you make cars, you can use press machines to stamp out car parts from metal. This ensures that the components of the car fit together perfectly. In the food industry, press machines are used to extract juice from fresh fruits and to form dough into sweet cookies. How much harder would it be to make all these everyday items without press machines would take however long it takes.

Not just corporations; anyone who wants to create (cut/press machines). You can shape some fabric into a pattern that would suit a green dress or a shirt with a press machine, if you enjoy sewing. In this way, you can make your clothes appear exactly how you would like them to. If you are an artist, it can print your beautiful designs onto paper or canvas. Share Your Artworks With Everyone Imagine Armed with a press machine, the amount of things you can create with it is limitless.

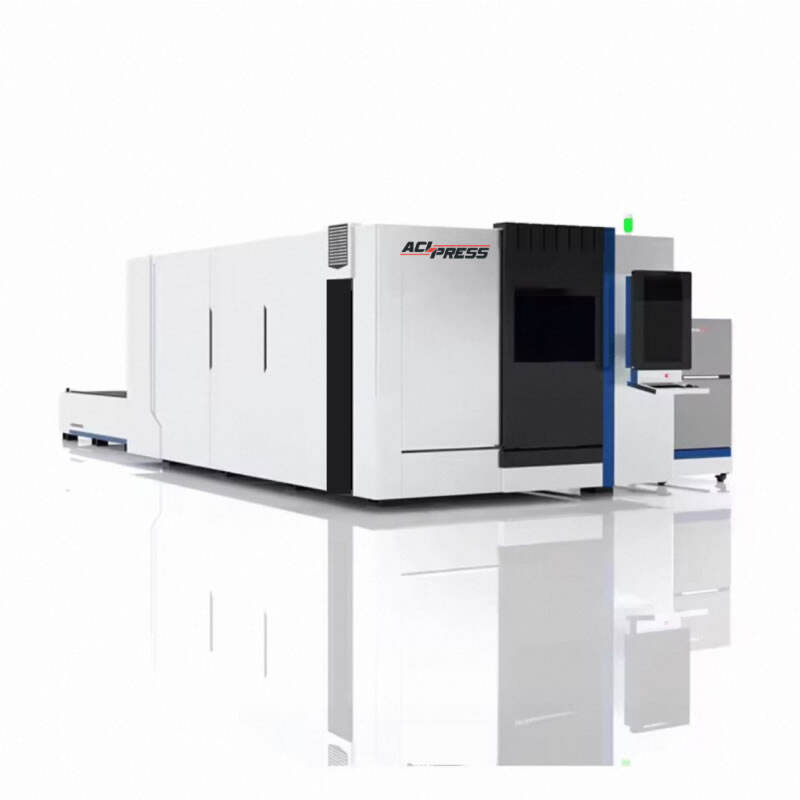

ACLPRESS is not just home to the press machine of precision equipment for the processing of press brakes but also various precision inspecting tools to spot defects in the product, and ensure reliability and stability. We also offer a comprehensive after-sales support.

ACLPRESS is a leader for processing and customizing products. It is proficient in the specifics of the bending of sheet metal and can offer customers the most efficient solutions, built on production drawings as well as requirements and conditions to assist them in reaching their press machine.

ACLPRESS boasts a significant production capacity due to its CNC machines like a CNC Gantry Machine CNC 4-axis machines and CNC precision grinders It also operates the heat treatment workshop which can process press machine fast and precisely In addition it houses a debugging centre is specifically designed to ensure prompt completion of customer orders and the exact fulfillment of their needs.

ACLPRESS has been active in the steel metal bending industry for over 20 years. We have press machine in sales and production, and we can assist customers in addressing and solve issues in numerous product types. Our team of experts provides round-the clock technical support 7/24 to ensure speedy and high quality service delivery.