It’s crucial to be precise when making metal objects. That means that everything needs to be on point. When it comes to 3D modeling, small mistakes can turn into big issues. And that’s where hydraulic press bending dies find their use. These tools enable metalworkers to easily and accurately create precise bends and curves.

A hydraulic press is a sub-atomic type of machine that utilizes a lot of pressure to change the shape of metal. This machine has a special part called a bending die. This has a special form in which directs the metal when it is worked. It nestles inside the hydraulic press and helps ensure the metal bends where it needs to. This is very useful as you wouldn't want to make complex shapes without this tool because such shapes are almost always needed in different projects.

The bending dies are great tools that worked for various metal projects. Various types and sizes are available depending on the application. Some dies are flat and uncomplicated, while others are complex with many folds and angles. This diversity makes them great for different jobs and gives metalworkers the opportunity to create an array of unique designs.

Winding dies are also incredibly strong and long lasting. They are crafted from durable materials that withstand the pressure and heat of metalworking processes. This is, they can be reused over and over and will not wear out soon, getting the same good results with each use. Metalworkers trust bending dies because they are so reliable and quality craftsmanship.

A custom bending die is designed for this specific metalworking project. This implies that it is custom-built to suit the requirements of that specific project, thus it helps enhance accuracy and reduce wastage. As the die is only and specifically made for that job, they can smooth and speed up the bending procedure. Custom dies can also help speed things up, which is very beneficial in a busy workshop as this way you can accomplish much more in less time.

This hydraulic press is so powerful that it is sometimes difficult to determine the shape of the metal. That’s where bending die comes into play. The die accurately directs the flow of the metal to form the desired shape. This accuracy is particularly important when creating components that interlock in machines or buildings.

Fully equipped bending dies: We are not the leads in materials, but we offer various types (even custom ones) depending on your project. From the most basic die for a simple shape to intricate dies for complex patterns, we have what you need to get the job done right. Our aim is to ensure you have the proper tools for your metalworking projects, so you can accomplish them efficiently and effectively.

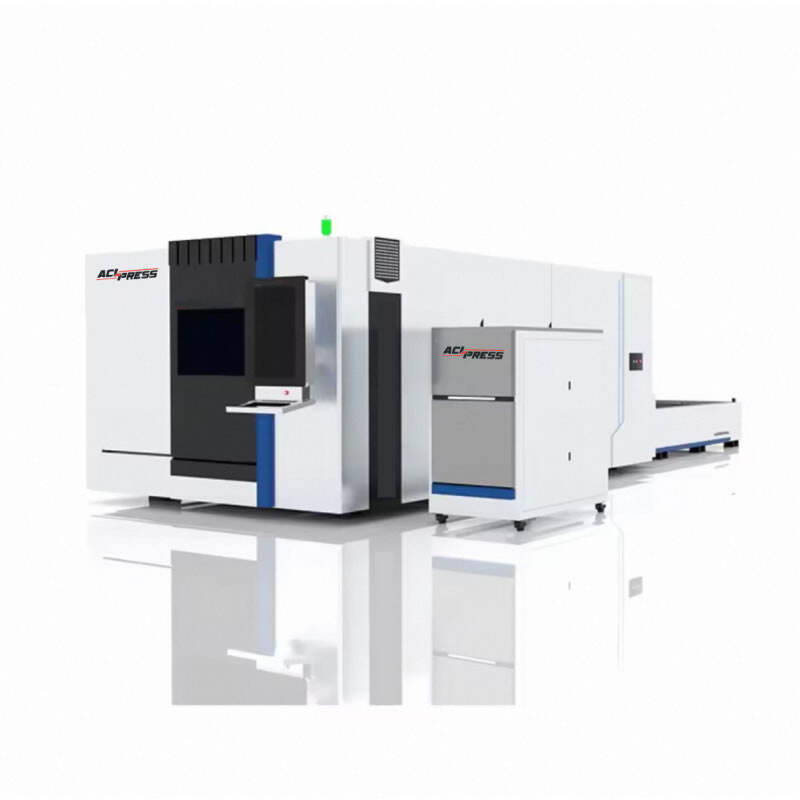

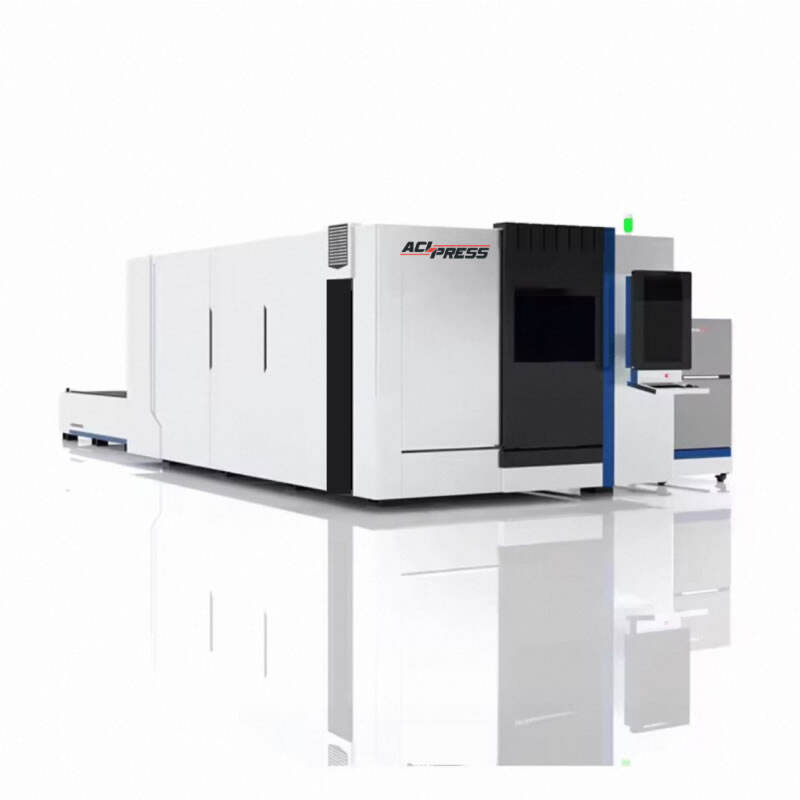

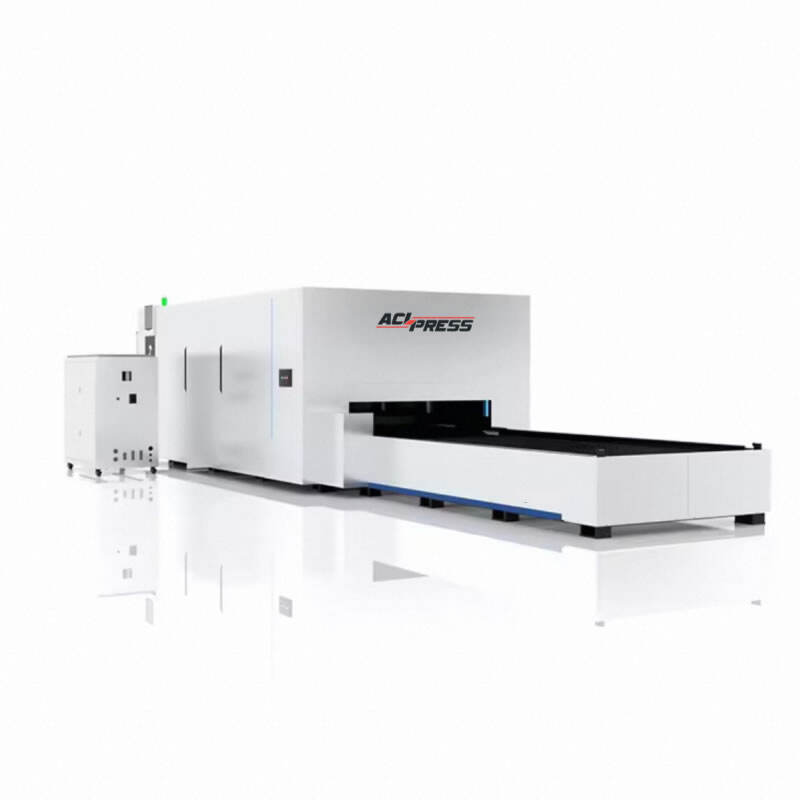

ACLPRESS offers not just the most extensive selection of precision equipment for the processing of press brakes but also numerous precision inspecting tools to spot issues with products, bending dies for hydraulic press durability and reliability. In addition, we provide comprehensive after-sales service.

ACLPRESS is an expert for processing and customizing products. ACLPRESS is very familiar with the specifics of sheet-metal bent, which allows it to provide customers with optimal solutions bending dies for hydraulic press on their production drawings demands, requirements, and other specifications.

ACLPRESS is actively bending dies for hydraulic press in the steel metal bending industry for more than 20 years. With a wealth of sales and production experience, we can aid our customers in resolving problems across a variety of applications for our products. Our dedicated technical team provides all-hours technical support to ensure quick and high quality service delivery.

ACLPRESS a substantial production capacity due to its bending dies for hydraulic press which include a CNC gantry machine CNC 4-axis machines and CNC precision grinders. Additionally it a heat treatment workshop which handles various spare parts efficiently and accurately. The facility also houses a debugging centre ensures orders placed by customers are delivered on time and precisely.