With the industry developing various products by changing the looks and feel of the materials, press brakes are crucial tools that play a significant role. Her dedication to confidence shines through in her teaching, and her experience leading classes has not only informed her understanding of teaching but also the machines, which are currently all the rage in factories. This enables them working much quicker and error-free than humans, resulting in greater production in lesser time. The forming machines take on all shapes and sizes. They are utilized in multiple fields, including the manufacturing of metal components, the production of plastic products, and even in food processing. It is a form which demonstrates how versatile these machines are in assisting to manufacture a variety of products.

Forming machines is help 강요 making them do that automatically. Translation: This means that things which were once completed manually by human beings can now be handled by machines – and that saves both time and money. Before the advent of brake presss, for instance, workers would have to cut, bend or stamp metal or plastic manually. This process was frequently quite slow and potentially error-prone, resulting in inaccuracies. Now, with the aid of these machines, the process is considerably quicker and the outcomes are more dependable. Factories can make more products and make sure they’re better quality than ever before. Not only does this accelerate efficiency but it also allows producers to fulfill the latest consumer demands.

Each forming machine is unique, as there are different types of them with a specialization in a particular field. While many types of equipment can be used for this process, some of the most common types are press brakes, roll-forming machines, and punch presses, which are commonly used in the manufacturing of sheet metal products. There are also injection molding machines for creating plastic parts, and extrusion machines for forming complex shapes. As such, other machines, namely 3D printers or CNC machines, are used in other fields, e.g. engineering, medicine, or building structure. For example, different types of machine, produce different product. There is a need to know about the different machines to select the right machine for a sure job or project, which will make sure that the best results are achieved.

One of the major benefits of using automated forming machines is that these machines can work 24/7 without feeling fatigue or require breaks. And, unlike their human counterparts, these machines don’t need to stop working, an impressive capability that allows a single machine to process more material in a fraction of the time than an entire crew of workers could. This can significantly maximize the efficiency of the manufacturing process. Automated machines also provide more consistent, accurate work since they do not make some of the same mistakes that people do. Manufacturers also programs these machines to do multiple tasks; a way of saving money while still being able to produce great quality products in a short period of time. This capability to perform different jobs efficiently, is one of the most significant reasons more factories are adopting automated forming machines.

Presses are extremely valuable to the metalworking environment because they can manipulate large amounts of material with minor effort. New metal forming machines, for example, can make parts so complex that they would be next to impossible to produce with older equipment. Utilization of the latest machines provides factories with the ability to form complicated shapes or detailed parts, easily. One of the great advantages of metal forming machines is they produce materials which are very uniform in thickness and size, while maintaining accuracy regardless of how much material is being worked. This enables manufacturers to produce metal parts on a standard basis, which can greatly reduce production costs.[10] Metalworking has used forming machines to revolutionize the entire industry, allowing more creativity, and creating efficiencies.

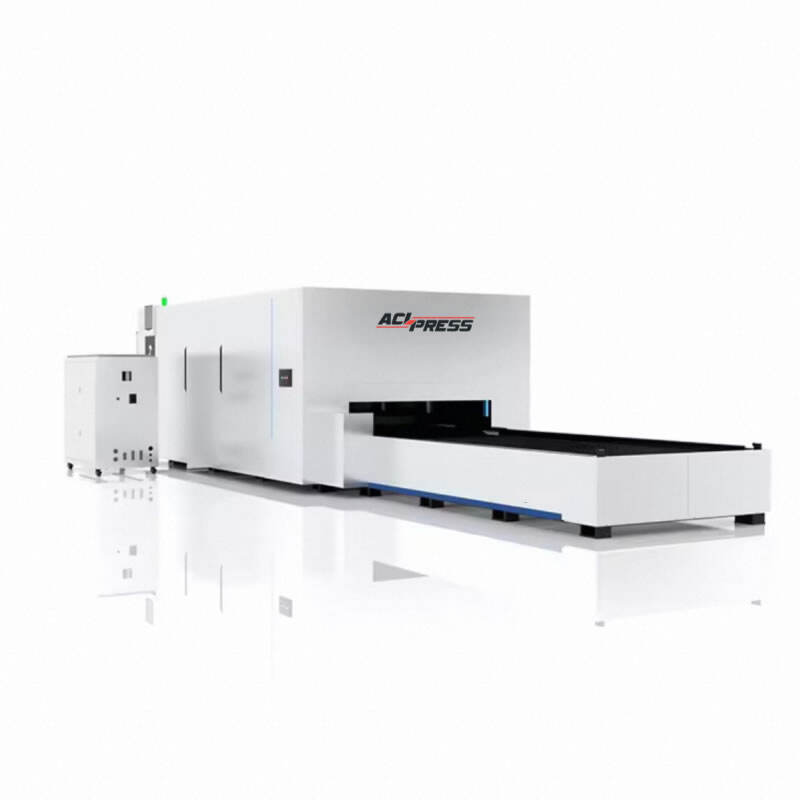

ACLPRESS has a large range of high-precision equipment that can process press brakes, as as a variety of inspection tools that detect problems in the product and assure its durability. Furthermore, we provide an extensive forming machine.

ACLPRESS is a leader in the processing of products and modifying them. ACLPRESS is well-versed in the particulars of sheet metal bent, which allows it to offer customers the best solutions based on their production drawings, forming machine, and conditions.

ACLPRESS forming machine a robust production capacity with numerous CNC machines which include a CNC Gantry machining centre CNC four-axis machining centers and CNC precise grinding machines. It also operates a heat treatment workshop treats various spare parts swiftly and precisely. It also a debugging centre to ensure the orders of customers are fulfilled punctually and accurately.

ACLPRESS is actively involved in the steel metal bending industry for more than forming machine. With a wealth of sales and production experience, we can aid customers with resolving problems across a variety of product applications. Our team of experts provides 24 hours of technical assistance to ensure quick and high quality service delivery.