The whole idea of the machining industry is to build durable parts and products that greatly benefit us in our lives. It is a major field and serves as one of the building blocks in industry. That everything from the cars that drive us to places, to prostheses and pacemakers is rapidly produced in a right-angled manner. That is why, at ACL we are constantly exploring new and innovative solutions to optimise our machining processes. We think innovation is the crux of producing good quality.

Some things we do to make our work better is by using CNC, or computer numerical control machining. It is a special technology in which machines are controlled by computers. So, basically what we are doing is a very repeatable process of forming parts. This way the pieces we build are less error-prone. This not only increases the quality of our products but also helps save us time and money. If we can prevent the mistakes, everyone is better off as our work will get done quicker.

In no uncertain terms, Automation is evolving as a significant criterion for service in the machining industry. Machines are becoming more intelligent and learning to work autonomously, the better technology gets. Doing so will make our job more productive and accurate. We are thrilled about robots, and how automation can be utilized in our operations at ACL Essentially this technology helps to increase the efficiency of our processes.

So we use robotic arms to assist in the loading and unloading of parts as one example. Our employees do not have to waste their time on such simple work and are able to perform more skilled-oriented tasks. These robots use their robotic arms to take care of the more menial jobs and free up time in production. Robots have the added benefit of being less risky for our workers to avoid injury in using them, making our workplace more safe all around.

Woodworking is a very difficult process, mainly due to the fact that many jobs require perfect realization and precision. This is where ACL's unique skills and insights are crucial. We have a close-knit team of engineers and machinists that makes collaborating easier to achieve the best result for each project we work on. They rely on our modern tools and software to do so.

In particular, we make use of something called 5-axis machining. This enables us to create more intricate and delicate components. We could work at different angles and in positions impossible to be done with regular machines that can only move on three directions which were very restricted also, but now thanks to technology those restrictions are history. With 5-axis machining, we can provide parts to our customers without sacrificing on quality.

Because we partner, and not just serve our clients. We can therefore deliver unique solutions built specifically for them. Our commitment to innovation, automation & the environment is why we are leaders in the machining industry We have a vision and desire to join forces with our clients in reaching their objectives while successfully delivering on the projects.

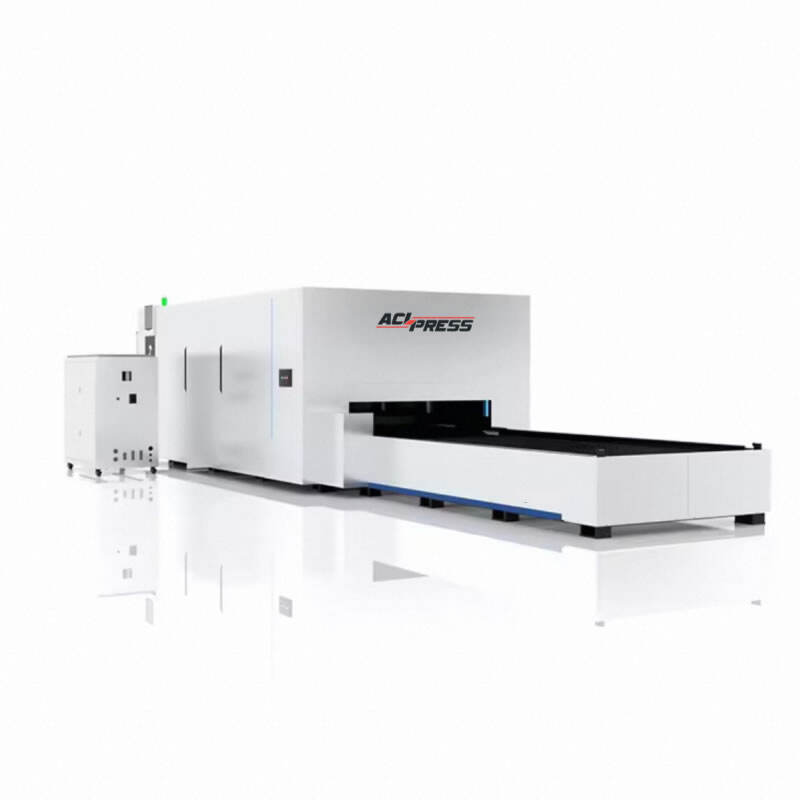

ACLPRESS machining industries a robust production capacity with numerous CNC machines which include a CNC Gantry machining centre CNC four-axis machining centers and CNC precise grinding machines. It also operates a heat treatment workshop treats various spare parts swiftly and precisely. It also a debugging centre to ensure the orders of customers are fulfilled punctually and accurately.

ACLPRESS has exceptional capabilities in processing and customizing products. ACLPRESS is well-versed in the particulars of sheet metal bends, which allows it to offer customers the most efficient solutions in line with their production plans machining industries, requirements, and other specifications.

ACLPRESS has been active in the industry of steel metal bending for over 20 years. We have a wealth of experience in sales and production, and we can assist customers in addressing and solve issues in a variety of product applications. Our skilled technical team offers round-the clock technical support machining industries to ensure timely and efficient service delivery.

ACLPRESS machining industries not only an extensive range of high-precision equipment for the processing of press brakes but also various precision inspection tools to identify product issues, ensuring product quality and stability. We also offer a comprehensive after-sales service.