Metal benders are people who use their strong platters and special equipment to tailor metal in antique and modern designs. Do you ever have to see a fence, metal and have beautiful and intricate patterns? This one was made by some talented metal bender! All these artists apply their creativity and qualifications, their work contributes a lot to aestheticizing our environment.

These "sheet metal bending dies" are like artisans, specializing in metal. They employ their imagination and creativity to come up with visually alluring designs that draw our attention. Gates, railings, and even incredible sculptures are made from metal, and they can do everything! Through this, metal benders assist with keeping our reality looking pleasant or entertaining, improving sure spaces we visit occasionally.

This first step is essential, because when press brake begin a new project, they take time to consider what they are going to make. They reflect on a variety of concepts and designs that spark ideas within them. Once they settled on a concept, they sketch their ideas out on paper to visualize how it would look. When they have a clear plan, they get to work with the metal. To bend the metal, they sometimes heat it to make it softer. They shaping the metal into the design they envisioned with both machines and their hands. This stage of the process is much trial, skill, practice and patience! This is more than manipulating metal; it is bringing something unique into existence.

Those that are a master of the earth always think of new ways to create. They tap their imaginations to generate new ideas and new methods. For instance, they may test new techniques for bending metal, or experiment with different metals in their designs. This brainstorming process is paramount as it keeps metal benders cultivating the ideas that will ultimately shape the future of their craft.

There is a history of metal bending and it is interesting. It's been there for a myriad of years, starting with rudimentary hand tools and working hands. Back then, tools for metal forming were basic and all needed metal benders was their brute strength and skill. But with progress in technology, there are now machines in metal forgers that allow them to operate at a considerable pace and efficiency. These machines enable them to make more elaborate designs and take on bigger projects than ever. Over the years, metal bending has undergone several transformations, and metal benders are always looking for ways to hone their skills and creations.

Bending Metal is an art that needs a whole bunch of different abilities and loads of experience. Metal benders need to know how to run machines, manipulate metal accordingly and make sure that their designs are sturdy and stand the test of time. He has to be careful and patient because working with metal can be dangerous. Metal benders need to and should take safety seriously to protect themselves and others in their working environment.

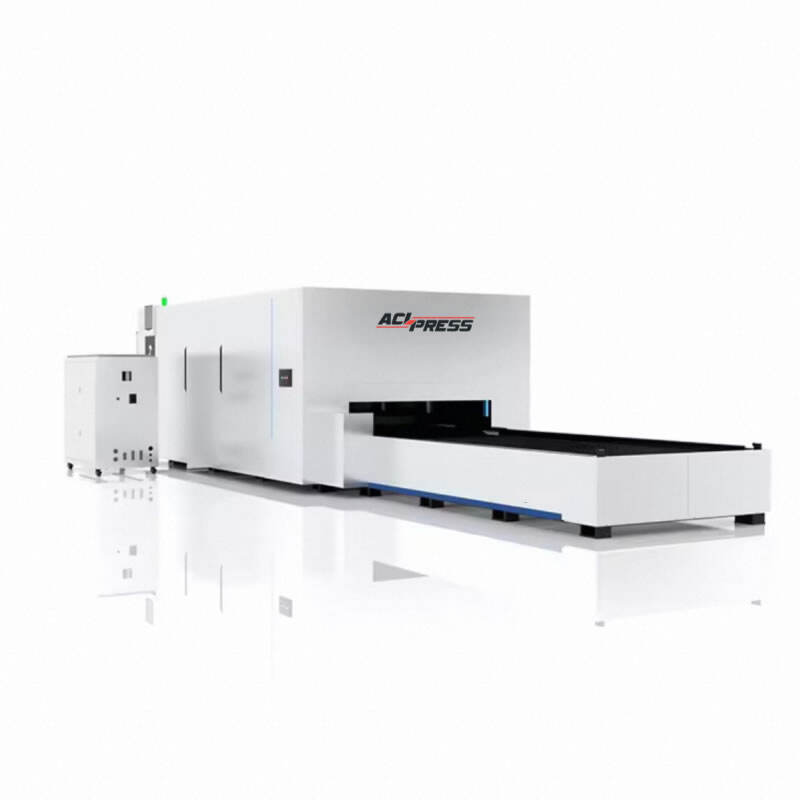

ACLPRESS metal benders not only an extensive range of high-precision equipment for the processing of press brakes but also various precision inspection tools to identify product issues, ensuring product quality and stability. We also offer a comprehensive after-sales service.

ACLPRESS boasts a metal benders capability which includes a wide range of CNC machine tools such as a CNC Gantry machining center CNC 4-axis machining centers as well as CNC precision grinding machines Additionally it a heat treatment workshop processes various spare parts quickly and accurately In addition it houses a debugging centre is specifically designed to ensure the completion of customer orders as well as the precise fulfillment of their requirements

ACLPRESS metal benders exceptional processing and capability to customise products. It is well-versed in the specifics of the bending of sheet metal which allows it to provide customers optimal solutions built on production drawings specifications, needs, and current conditions to help them achieve meeting their goals in business.

ACLPRESS has been active in the industry of steel metal bending for over 20 years. We have a wealth of experience in sales and production, and we can assist customers in addressing and solve issues in a variety of product applications. Our skilled technical team offers round-the clock technical support metal benders to ensure timely and efficient service delivery.