You might automatically think of objects like cars, skyscrapers, or even superhero armor that shields the heroes from harm. Metal is durable and you may remember it in more ways than one. However, metal is something capable of being modified to just about any fun shape. We at ACL have a lot of experience working with metal, now we want to pass that knowledge on! Read on to get an overview of the basic metal bending techniques for first-timers, expertly het up tips as well, how it works and a variety ways in which you could use this extraordinary concept with several projects!

Before we form any metal, here are some fundamental techniques you need to understand. 0 Getting the right tool for the job First, you need a hammer. Based on how heavy the metal and what contour you need to produce, there are a variety of tools involved these as brake press, roll bender or hydraulic push. Different tools, different feel. Secondly, grip the metal tightly to your tool. These are critical as they prevent the metal from shifting around while you attempt to bend it. With the metal held secure, use your tool to lower and bend the metal into place in small pressure increases until you reach angle desired. This is why you must work meticulously and very slowly, as the unfolding of sheet metal can be tricky if too much force gets applied the wrong way.

If you are a novice and this is your first step in bending metal, less heavyweight metals like aluminum or copper can be used for easier manipulation. This type of metal is more malleable and requires much less force than thick heavy metals like steel that need to be manipulated into place. This allows you to play around with different bending styles to figure out what you like best! Additionally, you could in all probability roll the metal or twist it and curve it differently. With continued practice, you will improve your pressure control and eventually be able to make more intricate shapes that are less simple.

As if by magic, but due to the laws of physics (science about how things work), you can bend metal If you push on a metal sheet, the molecules (very small pieces inside the material) get stretched and squashed. This stretching and squishing deform the metal. For any such bend that you make, the force required to bend a metallic sheet depends on various factors... 1) thickness of metal sheet,...2) angle up-to which it is bent and...,3)a type of metal(sheet). With an understanding of these core concepts, you can be more efficient and bend with greater accuracy, leading to better results!

Here at ACL, we are always seeking new and exciting opportunities to fold metal! We have invented some very unique techniques and tools that allow us to make shapes and designs never before achievable. We pride ourselves on testing the envelope of metal bending capabilities. Be it a signature piece of furniture or large architectonic element as attention catching, every time we decide to breakstones to give our best art work for the project with creative inspiration and intention.

From some very pretty art work done to your house hold items, metal bending has been used in a variety of innovative ways The most fun part of metal bending is the types of 3D shapes and curves you can make which are impossible to create in flat sheet. It is ideal for crafting sculptures, furniture and many ornamental aspects that enhance the character or style of your property. Metal can also be bent and molded for functional purposes—building custom brackets, or tooling parts on a machine to help make something run more efficiently.

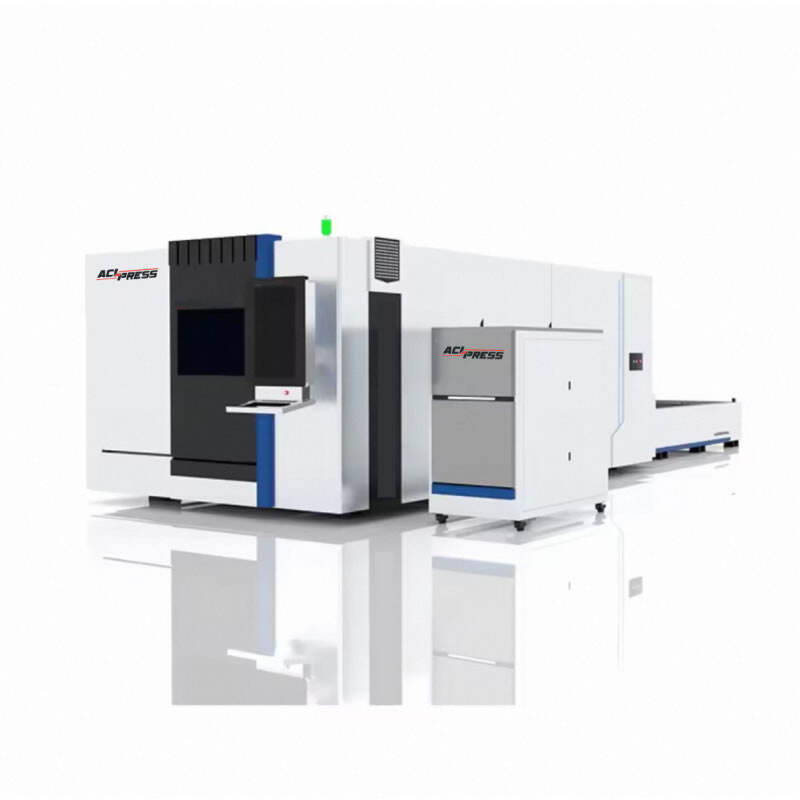

ACLPRESS bending of metal a broad range of precision equipment to process press brakes, as as a variety of inspection tools to detect problems with the product, and help ensure its dependability. Furthermore, we provide an extensive service after-sales.

ACLPRESS is involved in the steel bending business for more than 20 years. With a wealth of sales and production experience, we can assist our customers in resolving issues in a bending of metal of application areas. Our technical staff is available all-hours technical support to ensure prompt and top-quality service delivery.

ACLPRESS is an expert for processing and customizing products. ACLPRESS is very familiar with the specifics of sheet-metal bent, which allows it to provide customers with optimal solutions bending of metal on their production drawings demands, requirements, and other specifications.

ACLPRESS a substantial production capacity due to its bending of metal which include a CNC gantry machine CNC 4-axis machines and CNC precision grinders. Additionally it a heat treatment workshop which handles various spare parts efficiently and accurately. The facility also houses a debugging centre ensures orders placed by customers are delivered on time and precisely.