If you’ve ever seen anything that is made out of bent metal, such as a bicycle or mailbox, you may have thought about how it was made. Another method of developing metal is by press brake. The process uses a press brake machine to shape metal sheets without cracking or causing issues. The way this processes work is really interesting!

It is a very old method of deformation, and it is a very important method in many industries.Press bending It aids in producing all sorts of metal parts, from buildings and vehicles to furniture. This method is considered to be both reliable and effective. This means it can produce good-quality metal parts, quickly and accurately, suitable for a wide range of products. That is why press bending is adopted by many factories.

The press bending process is extremely accurate. It employs a powerful machine known as a hydraulic press that presses down on the sheet of metal. The press brake applies just the right amount of force to bend the metal into the desired shape beautifully. This technique is excellent because it guarantees that every non-linear piece appears exactly like the previous one, and thus the quality is consistent every time.

Depending on the metal’s thickness and shape, various press bending machines can work with a variety of shapes. It’s incredibly flexible, which means, it can generate everything from basic bends (like a gentle curve) to more complicated forms that resemble circles or waves. This is particularly beneficial for factories that require the mass production of thousands of specialized metal components. The shape variety ensures that manufacturers can accommodate a range of different projects.

It is widely used in press machining and is highly common for the processing of metal at factories. It is an intelligent method of creating metal components that must be high-quality and very precise. They can produce bend which is up to the mark and also within the parameters customers will require, in case factories use this method which is press bending. It is also quicker and more affordable than previous processes such as forging, which can take years and be highly expensive. They can create good products, without wasting their money or time, with press bending.

Press bending is another good thing, because it results to less wastes than other methods. Unlike milling, it does not have to remove unnecessary metal, making it a cleaner method for producing parts quickly. This is more eco-friendly as there is less scrap steel that would otherwise go to waste. The use of press bending can offer factories that emphasize environmental protection very great benefits.

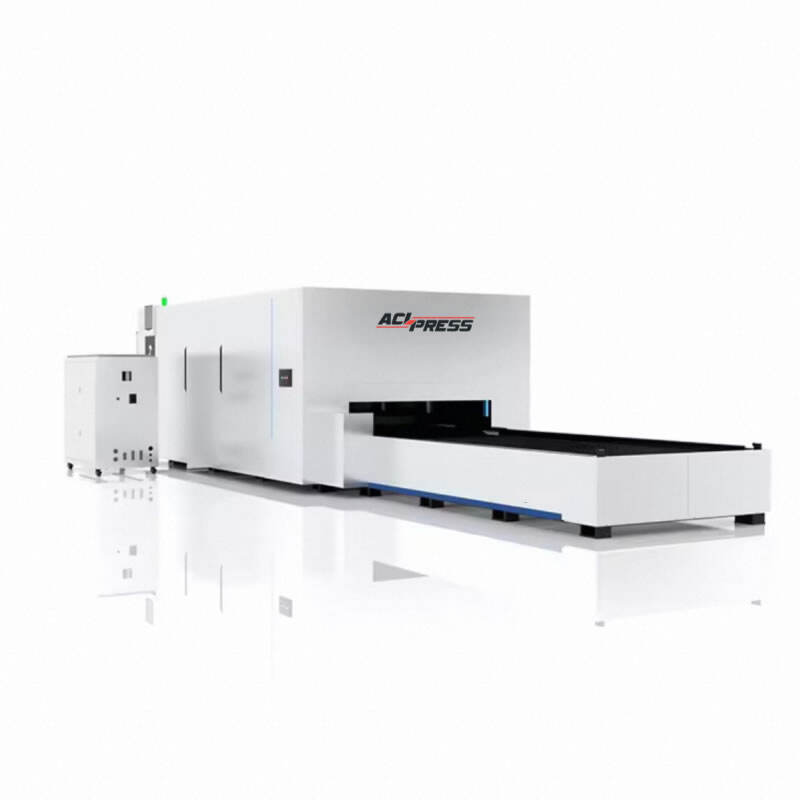

At ACL we have top of the line press bending machines, what we use best in its kind to manufacture quality metal pieces. Our specialized crew and tools can perform any special job and deliver high-quality outputs always. We are passionate about what we do and our focus is on quality.

ACLPRESS boasts a robust production capacity includes numerous CNC machines which include a press bending CNC four-axis machining centers as well as CNC precise grinding machines. ACLPRESS also an industrial heat treatment facility treats various spare parts swiftly and precisely. It also houses an individual debugging center is designed to ensure fulfillment of customer requests and precise fulfillment of their requirements.

ACLPRESS press bending a broad range of precision equipment to process press brakes, as as a variety of inspection tools to detect problems with the product, and help ensure its dependability. Furthermore, we provide an extensive service after-sales.

ACLPRESS is involved in the steel bending business for more than 20 years. With a wealth of sales and production experience, we can assist our customers in resolving issues in a press bending of application areas. Our technical staff is available all-hours technical support to ensure prompt and top-quality service delivery.

ACLPRESS possesses press bending and the ability to customize products. ACLPRESS is well-versed in the specifics of sheet-metal bending, allowing it to provide customers with the best solutions built around their production drawings demands, requirements, and other specifications.