In factories, machines are specific tools to produce many different goods. They do this by letting factories manufacture products quickly and conveniently. Some of the most commonly used machines are lathes, grinders, and milling machines. Every machine has its own task to perform and helps in production of diverse products.

Machines assist in the process of converting raw materials, such as wood or metal, into a finished product. This consists of few essential steps which are: First, you actually need to design the product you want to make. They create plans for the interface and the functionality of the product. Then they produce the raw inputs for the product. So they have to cut the wood to shape, for example if they are making a wooden table. At the end, they assembled everything to produce the final products. These steps are done much faster by machines, allowing businesses to produce more products in less time. This is quite beneficial for businesses as they are able to serve customers faster.

Factory machines are designed to last a long time and to be extremely safe. Well these machines have rules they follow to maintain how well they function and what kind of quality they produce. In factories, worker safety is paramount. They are built from durable materials such as metal, which allows them to withstand high usage in industrial factory settings.

For example, if a piece of equipment is in use 24/7 it has to be robust enough that it doesn’t come on the blink. All of the machines at ACL are purpose-crafted, ensuring that they meet all of the highest safety protocols. They are built with reliability, efficiency, and safety in mind so that everyone in the factory can use them without risk of injury.

Machines are highly advanced due to new technology, they are better and faster than previous machines. Note that this includes computer programs that assist the machines in performing tasks, robots that help produce goods, and automatic systems that expedite processes. These advances allow factories to run safer and faster, allowing for higher product quality and lower waste.

A machine can read a computer program that tells it exactly how to cut a piece of wood to fit with other pieces. All machines of ACL are last and most modern technology in their field. Factories are able to make the most out of the latest trends and be competitive in the market.

Today, Machines are designed connected with one another, like a team. This impacts the ability to share information and collaborate more effectively. When machines can talk, it improves the efficiency of the factory, where tasks can be done easily. ACL built machines with the latest connection technology, ensuring its products were the most efficient on the market.

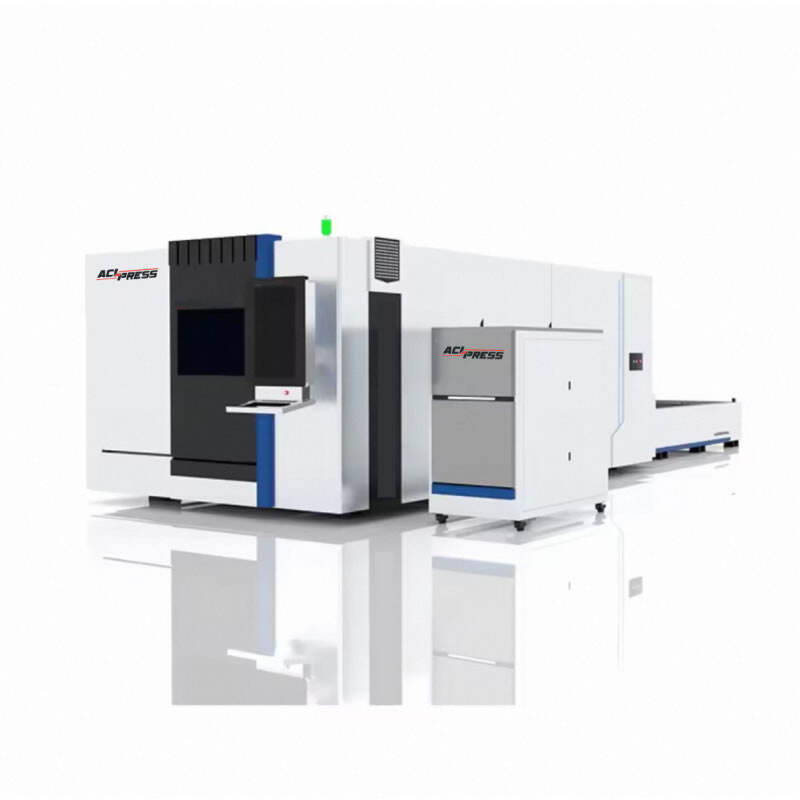

ACLPRESS technical machinery not only an extensive range of high-precision equipment for the processing of press brakes but also various precision inspection tools to identify product issues, ensuring product quality and stability. We also offer a comprehensive after-sales service.

ACLPRESS is a leader in the processing of products and modifying them. ACLPRESS is well-versed in the particulars of sheet metal bent, which allows it to offer customers the best solutions based on their production drawings, technical machinery, and conditions.

ACLPRESS boasts a robust production capacity includes numerous CNC machines which include a technical machinery CNC four-axis machining centers as well as CNC precise grinding machines. ACLPRESS also an industrial heat treatment facility treats various spare parts swiftly and precisely. It also houses an individual debugging center is designed to ensure fulfillment of customer requests and precise fulfillment of their requirements.

ACLPRESS is technical machinery involved in the steel metal bending industry for more than 20 years. With a wealth of sales and production expertise, we are able to assist customers in addressing and resolving issues across a wide range of products. Our technical staff is available all-hours technical support to ensure prompt and efficient service delivery.