When you require a metal bender that is safe, quick and low cost, the vertical press brake from ACL is extremely convenient for your commercial demands. Equipped with leading - edge technology, sturdy construction and multiple customised design features these vertical press brake provide high precision, delivering excellent accuracy for bending operations in sheet metal format.ACL brakes are built to perform in each type of environment for industrial applications. With low prices on so many great products, Eagle National Steel is the steel fabricator you can trust to have quality products you need at a price that won't break the bank.

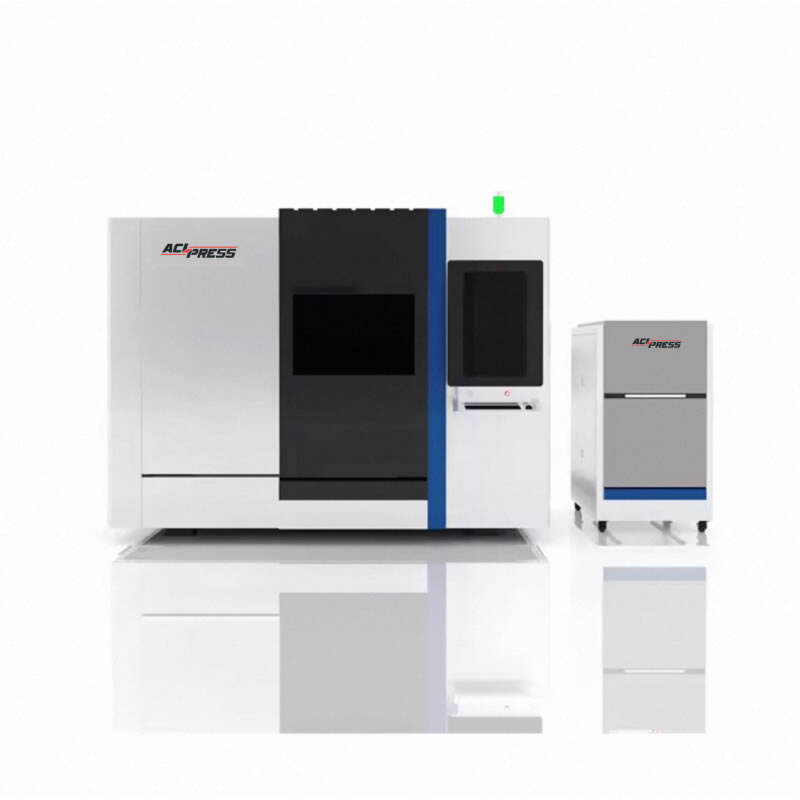

ACL Vertical Press Brake - Precision Metal Bending Machine This BB series model of metal bender are applies to light or medium work of the following: Channel, Joist, Angle, Bar Stock, TMT Low Carbon Steel Flat Stock and Sheet. No matter it is a thin sheet or thick plate, our press brake can make the work perfectly done. This vertical orientation provides the ability to have control over each bend, which is necessary for accuracy of the bends achieved for your project. Count on ACL's vertical press brake to help replace your aging equipment with accurate results.

At ACL, we are dedicated to utilizing the newest technology so that our vertical press brake machines have accurate and precise bending capabilities as well as easy programming. Our equipment provides self-engineered and high-tech features to speed up the bending cycle without compromising quality. From programmable controls with diagnostics to instantaneous feedback capability, ACL's vertical press brake is engineered for maximum productivity. You can rely on our state-of-the-art capabilities to deliver precision, speed and efficiencies in custom metal bending.

ACL's vertical press brake features a rugged steel frame and is designed to stand up to the rigors of an industrial environment. Our press brake is designed to be up and running immediately in any factory – busy or not. All the way from its robust frame to quality parts, ACL's Vertical Press Brake will make a long lasting addition to your shop floor. With the strength of our sturdy build, you don't have to worry about your machine outlasting your business – we guarantee that our product will provide years of reliable service.

We know that no two production runs are ever the same, so we have designed our vertical press breaks with customization in mind. Whether you require a particular tooling arrangement, a unique operating system or new safety features, our press brake is easily modified for your ideal processing. Our team of professionals will help you create the right system for your needs, so that you can enjoy the benefits of smart technology. You can rely on the fact that your vertical press brake will be built exactly the way you want it. Those custom options from ACL put you in control!

ACLPRESS is actively involved in the field of steel bending for over 20 years. With vertical press brake and sales knowledge, we can help our customers in resolving problems in a range of applications for our products. Furthermore, our technical staff provides 24/7 technical support, seven days a week, ensuring prompt and high-quality support to our customers.

ACLPRESS boasts a large production capacity with numerous CNC machine tools including a CNC Gantry machining center CNC four-axis machining centers and CNC precise grinding machines. Additionally it a vertical press brake workshop to treat various spare parts quickly and accurately. Furthermore it houses a debugging centre is specifically designed to ensure fulfillment of orders from customers and the precise fulfillment of their requirements.

ACLPRESS possesses exceptional processing and the ability to customize products. It is proficient in the specifics of the vertical press brake that allows it to offer customers optimal solutions built on production drawings or specifications as well as actual conditions to help them achieve meeting their goals in business.

ACLPRESS is not just home to the vertical press brake of precision equipment for the processing of press brakes but also various precision inspecting tools to spot defects in the product, and ensure reliability and stability. We also offer a comprehensive after-sales support.