The press machine Press machine is one kind of special design use for mechanical press press, such as metal and other materials. It applies high pressure on a device known as a die. The die is crucial because it helps to give the pressed substance its new form. For decades, mechanical presses were one of the most common ways to produce products in factories and workshops around the world. These have made it a lot easier and quicker to form materials than previously.

Before the mechanical press came along, people had to do it all by hand. This way of creating products was quite labor-intensive and it proved difficult to produce goods that were uniform in size and shape. Then came mechanical presses, and then everything changed. This new technology enabled faster production of goods, creating a noticeable shift. They enable workers to produce higher volumes of products at once, which helps meet customers' needs faster. Mechanical presses can also create very complicated shapes which are difficult or impossible to make by hand. Such corrections enabled factories to assemble and produce quality goods efficiently.

A mechanical press consists of various components that all contribute to the successful operation of the machine. Some key pieces from it include:

A bolster, with the first part seated on top of the bolster to work appropriately, ought to be placed underneath the die to help the die appropriately. A moderate bite of hardware alters the material to be pressed while the die may accept numerous shapes and size, one regarding the produced item. Although the clutch may start or stop along with the movement, it assists the chain machine in firmly establishing a smooth process chain. Hence, each of these parts should work perfectly to ensure that the brake press is practical. However, Mechanical press machines are significant.

Material Constraints: If the materials that need pressing are either too hard or too soft, the machine won’t be able to machinate them. It can cause complications in production.

Safety Hazards: The second risk associated with using a washing machine is safety hazards which will depend on using and maintaining the machine. However, workers must be well trained and execute caution while working these machines.

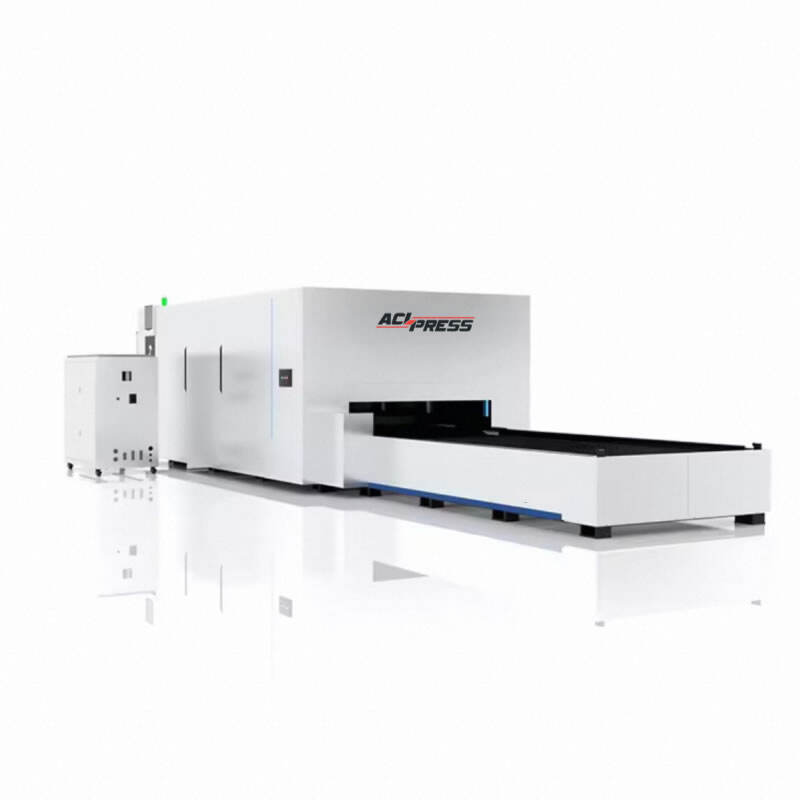

mechanical press machine a large production capacity thanks to its CNC machines like a CNC Gantry Machine CNC 4-axis machines and CNC precision grinders. Moreover it operates its heat treatment workshop can treat various spare parts quickly and accurately. It also houses a debugging center makes sure the orders of customers are fulfilled punctually and accurately.

ACLPRESS has exceptional capabilities in processing and customizing products. ACLPRESS is well-versed in the particulars of sheet metal bends, which allows it to offer customers the most efficient solutions in line with their production plans mechanical press machine, requirements, and other specifications.

ACLPRESS is not just home to the mechanical press machine of precision equipment for the processing of press brakes but also various precision inspecting tools to spot defects in the product, and ensure reliability and stability. We also offer a comprehensive after-sales support.

ACLPRESS is involved in the steel bending business for more than 20 years. With a wealth of sales and production experience, we can assist our customers in resolving issues in a mechanical press machine of application areas. Our technical staff is available all-hours technical support to ensure prompt and top-quality service delivery.