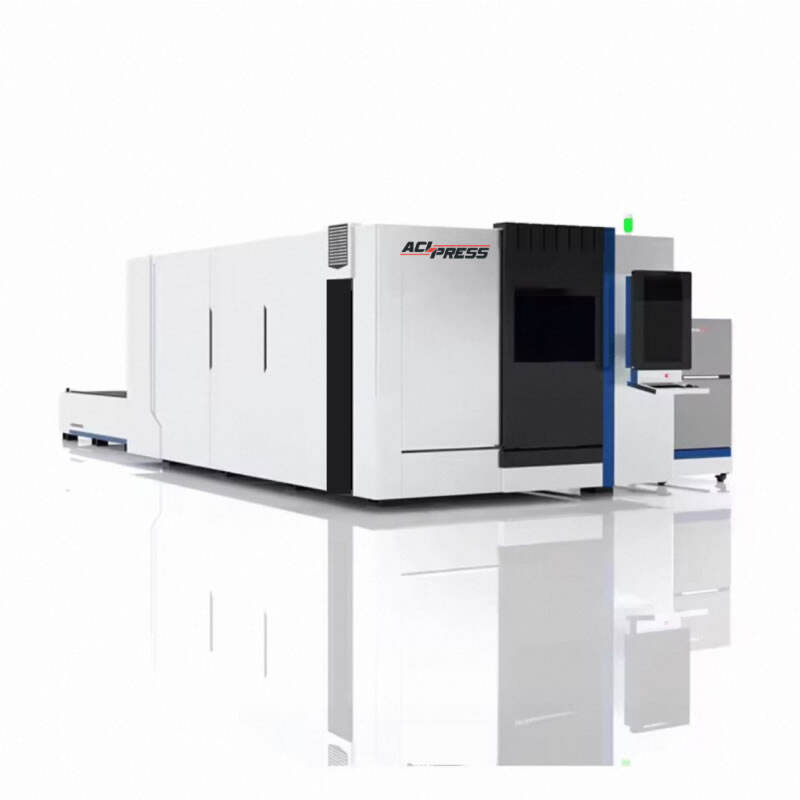

Laser cutting machines are advanced equipment that utilize powerful lasers to cut metal tubes. These kind of machines are a game changer as they streamline the process of tube cutting. The ACL is one such machine manufacturer. They manufacture high performance laser cutting machines useful for the factories and manufacturing.

Laser cutting is a process that utilizes a specific type of light beam. This beam is extremely strong and narrow, enabling it to cut through numerous materials. It has the ability to cut various materials, including metal, wood, and plastic. Laser cutting technology has existed for some decades, and it has been continuously improved. That means higher performance and efficiency compared to before.

This makes it possible for manufacturers to have extremely precise and high-quality cuts in metals done using laser services, since the devices are mostly used in factories. This, allowed the manufacturers to save significant time and money. The laser beam is so exact it can slice aside thick materials, with no impact to the region about the minimize. This degree of precision is one of the key reasons behind laser cutting's prevalence in manufacturing.

This means it can work with a lot of different kinds of metal, which is another avoid advantage of the laser machines for tubes. That includes things like steel, aluminum and copper. This enables manufacturers to produce a greater variety of products using a single machine. Such flexibility is crucial for companies that need to manufacture various products with short lead times.

Tube Laser Cutting machines assist in simplifying the work of tube cutting. They are programmed to saw tubes of various diameters and wall thicknesses. That means workers don’t have to cut tubes by hand as much. Instead, they can program the machines to cut the pieces on their own. This saves a significant amount of time and minimizes the manual labor to be performed.

Due to the use of laser machines to cut the tubes, the precision and the accuracy achieved by the manufacturers can be increased greatly. As a result, the products they design are of a consistent quality. For businesses, consistent quality is a critical factor that fosters trust with customers. When customers can trust that they can depend on products from a company, they tend to return more customers.

Laser cutting machines have another advantage, which is their speed. Cutting a tube takes a long time when using traditional cutting methods. With laser cutting machines, however, slicing through one tube takes all of several seconds. This speed is particularly useful for high-volume factories, which require fast production of large quantities.

ACLPRESS has exceptional capabilities in processing and customizing products. ACLPRESS is well-versed in the particulars of sheet metal bends, which allows it to offer customers the most efficient solutions in line with their production plans laser cutting machine for tubes, requirements, and other specifications.

laser cutting machine for tubes a large production capacity thanks to its CNC machines like a CNC Gantry Machine CNC 4-axis machines and CNC precision grinders. Moreover it operates its heat treatment workshop can treat various spare parts quickly and accurately. It also houses a debugging center makes sure the orders of customers are fulfilled punctually and accurately.

ACLPRESS has been actively involved in the laser cutting machine for tubes industry for more than 20 years. We have a wealth of experience in sales and production, and can help customers address and resolve problems for a variety of product applications. Our dedicated technical team provides all-hours technical support to ensure speedy and quality service delivery.

ACLPRESS laser cutting machine for tubes not only an extensive range of high-precision equipment for the processing of press brakes but also various precision inspection tools to identify product issues, ensuring product quality and stability. We also offer a comprehensive after-sales service.