Tube laser cutting is a novel and effective process for producing parts with high precision. This is an innovative technology used at factories where different products are being manufactured. ACL is one of the amazing companies that provides great laser cutting services. They are committed to helping companies make the best products they can. In this article we will cover all you need to know about press brake: advantages, where it is used and special requirements.

There are also professions where task accuracy is very essential because it is linked to the health well-being of individuals. For instance, medical devices should fit exactly, ensuring that they both work and aid in delivering the best possible medical treatment. It is when the parts aren't machined accurately, that bad things happen. In the automotive world, cuts that are made with precision make sure that the pieces of cars assemble in a safe way and operate perfectly. It's vital to help keep drivers & passengers safe out on the roads.

There are many great advantages of brake press technology offered by ACL located in Toronto Canada, which is why it is a popular choice for many manufacturers. [[First, it is way faster and more reliable than older cutting methods like sawing or drilling. Because a computer controls the laser, tube laser cutting is fast. This computer helps guide the laser, so it makes cuts in the metal and it does it fast because that saves time.

One of the biggest advantages is that tube laser cutting can handle a variety of tube shapes and sizes. This is significant because most firms have to manufacture products that are not identical. And it's easy for the laser's settings to be adjusted at the computer for different shapes and sizes of tubes. Each project can be tailored to meet the requirements of the business.

ACL's tube laser cutting can help bring special designs to your projects, which can make them unique and interesting. Adoption of this technology enables businesses to mold any shape or design they wish which helps them create products that are different from others in the market. One great thing about products, and why they can be very attractive to customers, is their customization.

Moreover, businesses can give their customers some unique touch to individual items. It means they can customize products to suit their clients’ likes and habits. This versatility in design allows businesses to enhance their branding by introducing distinctive and recognizable designs and packages. Instead, when customers find something special, they can associate the brand with a remembered moment and, in turn, want to buy again.

In addition, with the digitization of the cutting process, enterprises can minimize the risk of mistakes in the production phase. There is also an added benefit where increasing the general quality of the products produced allows the business to make more products in less time. This means that companies can operate more effectively and build better products for their customers with ACL's tube laser cutting technology.

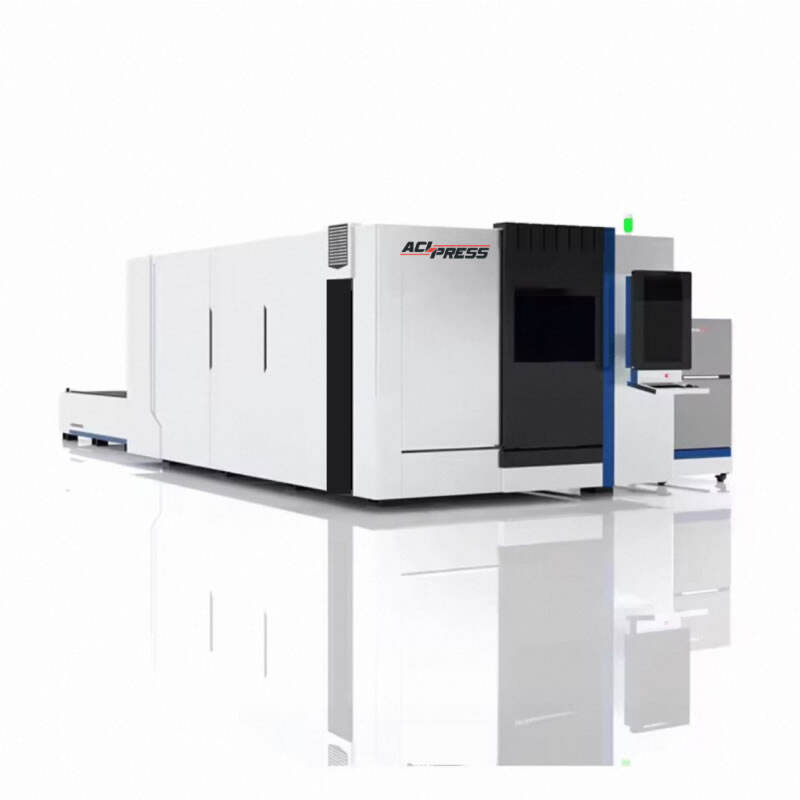

ACLPRESS a substantial production capacity due to its tube laser cutting which include a CNC gantry machine CNC 4-axis machines and CNC precision grinders. Additionally it a heat treatment workshop which handles various spare parts efficiently and accurately. The facility also houses a debugging centre ensures orders placed by customers are delivered on time and precisely.

ACLPRESS has been active in the industry of steel metal bending for over 20 years. We have a wealth of experience in sales and production, and we can assist customers in addressing and solve issues in a variety of product applications. Our skilled technical team offers round-the clock technical support tube laser cutting to ensure timely and efficient service delivery.

ACLPRESS is not just home to the tube laser cutting of precision equipment for the processing of press brakes but also various precision inspecting tools to spot defects in the product, and ensure reliability and stability. We also offer a comprehensive after-sales support.

ACLPRESS is an expert for processing and customizing products. ACLPRESS is very familiar with the specifics of sheet-metal bent, which allows it to provide customers with optimal solutions tube laser cutting on their production drawings demands, requirements, and other specifications.