A sheet metal bending dies is a significant machine it helps the users in metal operations. They are also used in many metal projects, be it construction or even metal art projects. The ACL sheet rolling machine is a great tool for bending metal sheets into the desired shape. They are loyal servants that want to make your life more usable.

So, how does all this work? It’s quite simple! You grab a sheet of metal, which is just a flat piece of metal, and you run it between a couple of huge rollers. These rollers rotate in opposite directions, which is how you get the metal sheet to pass through to bend it to your desired form. Using this process, you will be able to create all sorts of shapes and sizes for your metal projects, from long pieces for bigger jobs to small pieces for more intricate designs.

If you own a metalworking shop, you know that it is crucial to create things faster and more easily. A Sheet rolling machine can really help you in streamlining your work. This allows you to complete your tasks more quickly and efficiently. When you use a machine to bend the metal instead of doing it by hand, it will save you a lot of time and effort. It also means you can get much better results, as the machines are designed for precision. So with ACL's High Quality Sheet Rolling Machines, you will not only achieve a high quality work; you shall be assured of smooth and efficient working which will further make each project a lot more enjoyable.

Sheet rolling machines from ACL not only provide well-done work; they are also extremely versatile and reliable. That means they are applicable for various kinds of metalworking projects. They work with everything from sheets of thin aluminum to thick plates of steel. This is great flexibility as it means no need for different machines for different tasks.

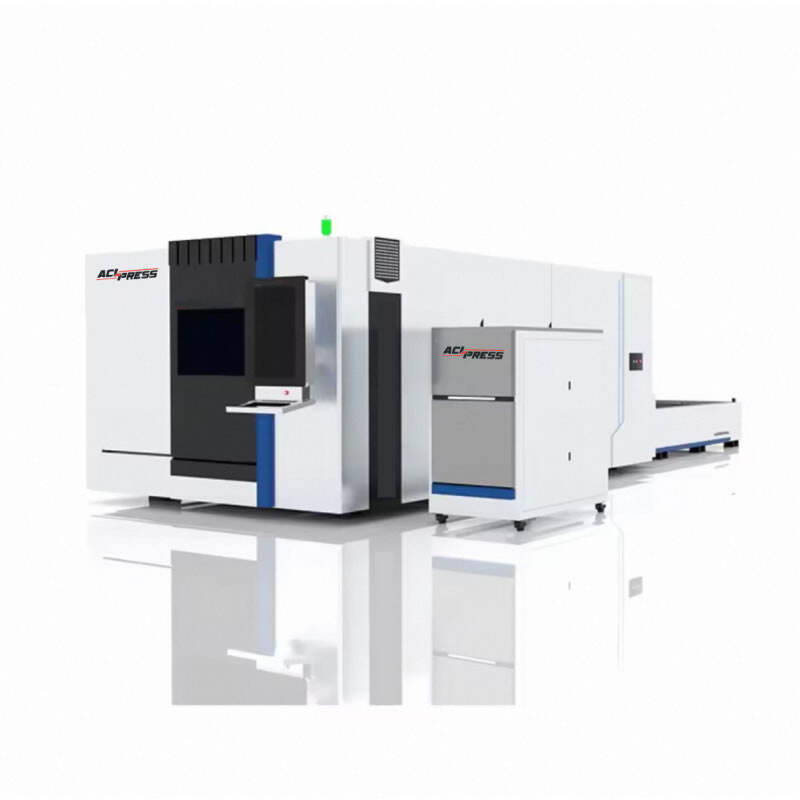

These machines come with many features that provide user-friendliness. They have, for instance, adjustable rollers to change the thickness of the metal that get processed. They also have easy-to-read displays that tell you key information about your project. With fine-tuned controls, you can ensure each piece you produce is exactly to your liking. ACL’s press brakes can help you tackle the job, whether you are in a small hobby shop at home or a commercial manufacturer in a factory.

Apart from their strength these machines have a lot of great features. They have removable rollers that suit various sizes of metal sheets, for instance. The controls are straightforward, so you don't have to be an expert to drive it. Plus, the digital displays give you all the info you need to keep an eye on your work. So when you purchase an ACL machine, you can be sure that you are receiving the best value for your dollar backed up by exceptional customer service and support!

So if you making one or one hundred of them, you can trust that it will be produced the same way. In addition, because our machines include durable materials, you know they will work perfectly for years. So, whether you are a hobbyist who likes tackling projects in your spare time or a professional metal worker taking on big jobs, ACL's sheet rolling machines will become your components of choice for getting the highest level of precision and consistency in what you do.

ACLPRESS is actively involved in the steel bending business for more than 20 years. With extensive production and sales knowledge, we can help clients in addressing issues in a broad range of product applications. Our sheet rolling machine provides round-the-clock technical assistance, 24 hours a day providing prompt and top-quality service to our customers.

ACLPRESS sheet rolling machine not only an extensive range of high-precision equipment for the processing of press brakes but also various precision inspection tools to identify product issues, ensuring product quality and stability. We also offer a comprehensive after-sales service.

ACLPRESS a substantial production capacity due to its sheet rolling machine which include a CNC gantry machine CNC 4-axis machines and CNC precision grinders. Additionally it a heat treatment workshop which handles various spare parts efficiently and accurately. The facility also houses a debugging centre ensures orders placed by customers are delivered on time and precisely.

ACLPRESS sheet rolling machine exceptional processing and capability to customise products. It is well-versed in the specifics of the bending of sheet metal which allows it to provide customers optimal solutions built on production drawings specifications, needs, and current conditions to help them achieve meeting their goals in business.