Many different shapes can be formed using the sheet metal bending dies. For example U-shape, V-shape and curved shape. This is very useful for making special designs that require a lot of effort and food bending. The machine copies for us and does not copy to the extent that its device prints cool and our products.

We designed this machine to work in our favor. It has some special guide tools, such as gauges and marks that tell us precisely where to bend the sheet. This ensures that our items are neatly formed and fit together well. We never have to worry about our work looking sloppy and unprofessional when we use this machine.

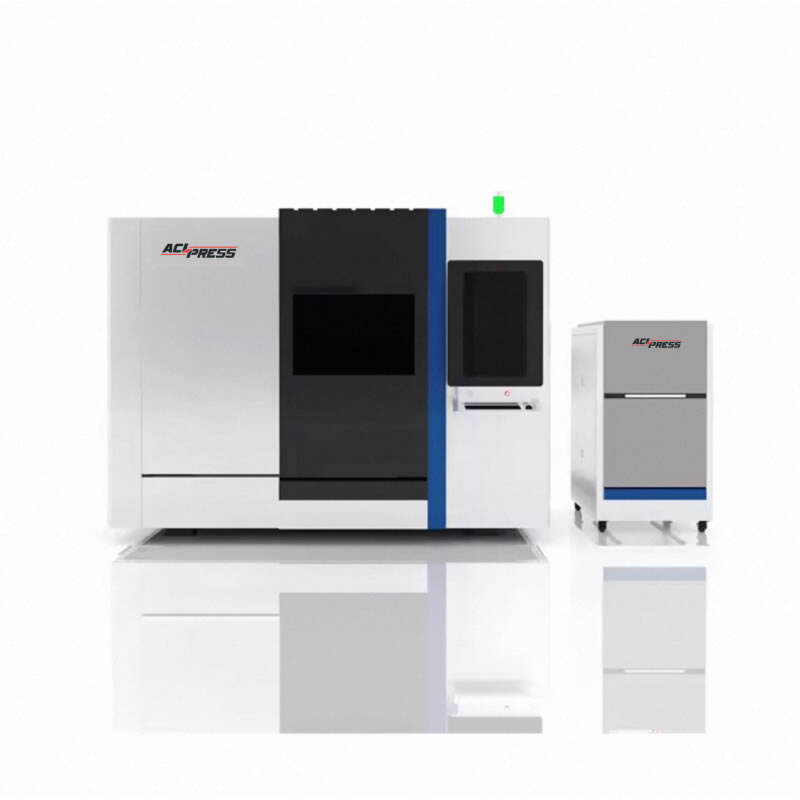

When we use any machine safety is really very vital. To prevent us from getting injured while using it, the ACL press brake comes with plenty of safety features. For instance, it has a foot pedal, so an operator can use both hands to operate the machine. This moves their hands clear of the danger zone, where metal is being shaped.

Another benefit is that the ACL sheet bending machine is very user-friendly. It has a straightforward control panel that lets us set how much we bend the metal and how quickly we want to do it. Thus, even those without metal forming experience are able to utilize this technology.

We use this machine to create metal furniture, machine parts, and electrical panels, for example. ACL sheet bending machine — because of its versatility in different applications — is a necessary tool in the metalwork bacause of the versatility of the ACL sheet bending machine. It is crucial for manufacturing high-quality products because of its capacity to precisely and carefully bend metal.

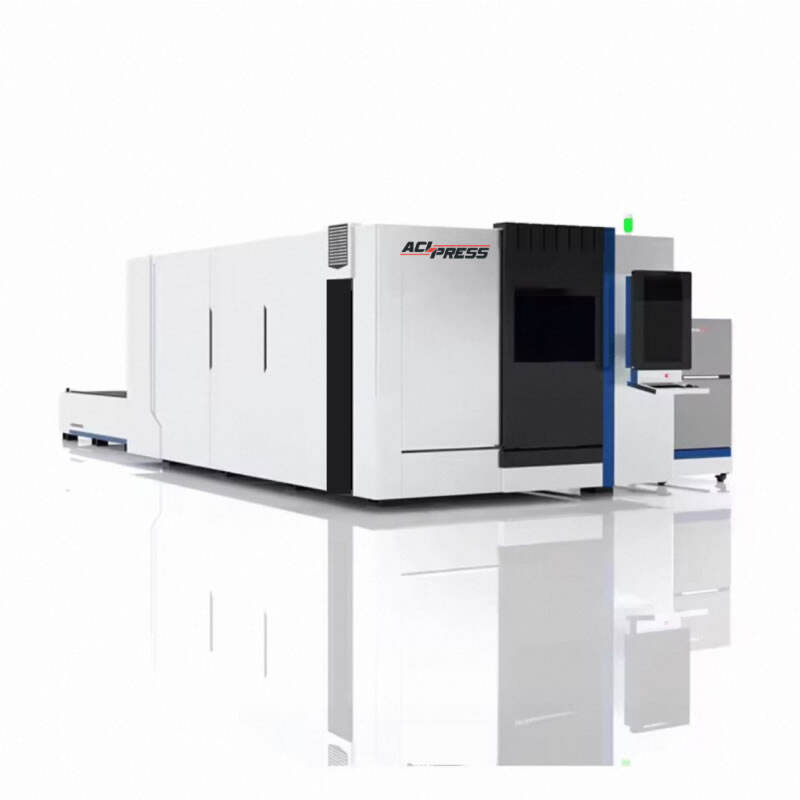

Hand bending of metal sheets is a time-consuming process and requires effort. But with ACL automatic sheet bending machine, we'd work more effectively and cover so much more in less time. This machine is equipped with a mechanism that allows the metal sheets to be fed into the machine automatically.

The ACL automatic sheet bending machine can be operated by the computer. Ideal for busy workshops it allows us to create many pieces tape on a short period of time. The machine also has a storage system that can store multiple bending programs. This makes it very easy for us to change the products without needing to setup the machine every time.

ACLPRESS is a leader for processing and customizing products. It is proficient in the specifics of the bending of sheet metal and can offer customers the most efficient solutions, built on production drawings as well as requirements and conditions to assist them in reaching their sheet bending machine.

ACLPRESS offers a wide range of equipment with precision to process press brakes as well as a variety of inspection tools that can sheet bending machine in the product and assure its dependability. We also provide a full after-sales service.

ACLPRESS a substantial production capacity due to its sheet bending machine which include a CNC gantry machine CNC 4-axis machines and CNC precision grinders. Additionally it a heat treatment workshop which handles various spare parts efficiently and accurately. The facility also houses a debugging centre ensures orders placed by customers are delivered on time and precisely.

ACLPRESS is actively sheet bending machine in the steel metal bending industry for more than 20 years. With a wealth of sales and production experience, we can aid our customers in resolving problems across a variety of applications for our products. Our dedicated technical team provides all-hours technical support to ensure quick and high quality service delivery.