Rolling bending is a precise mechanical technique to bend materials without resulting to fractures. We take metals and other materials and turn them into the different shapes that we require for a range of projects. ACL is no stranger to press brake, and we are looking forward to sharing our expertise with you!

Rolling bending has been used by people for thousands of years. The Egyptians used this technique to make strong and useful weapons in ancient times. Now we have these sophisticated machines that make it easier to roll and bend materials more precisely. The Three-Roll Push Bending Technique is one of the most popular way that we using it today. In this method, three rollers are moving around. This allows the material to hold better shape because the rollers all cooperate to keep the material in line.

Know your materials There are several materials that you could be bending, so you need to have a good knowledge of what you're about to work with if you want to master brake press. The bending behavior depends on different material properties. Steel is a hard metal; in contrast, aluminum is softer, more flexible, so it will bend more easily than a stronger metal like steel. The shape of the material itself is also critical to the bending process. A piece of metal that is long and skinny will bend different than a piece of metal that is short and fat.

Rolling bending is especially for that, because rolling bending you will get a lot of various shape. It’s particularly good for producing complex or tricky shapes that can be difficult to create using other methods. For example, we can bend metal tubes into continuous curves and arcs through rolling bending. This skill is especially useful in the construction of bicycle frames, which must be strong and light, and the handles of umbrellas, which must be formed in a way that allows them to open and close easily.

Not only is rolling bending a useful skill but it is also grounded in physics. In bending a material, we are changing not only a shape but also its physical properties. Bending stresses the material, and too much stress can break or damage it. For this reason, it is much important to know how much load a material can sustain before failure.

Rolling bending science is an example of the physics of how bending works and the relative strength of different materials. This is a field where we have significant expertise at ACL. We draw on our extensive scientific knowledge base to ensure that our rolling bending machines are as safe to use as possible while also providing high quality end results every time.

Be Patient and Spend Time: Rolling bending is a very slow process sometimes, but rolling bending must be conducted very carefully. If you hurry it, it will be bad and may come out a bent piece of metal, not the designed shape you expected. Remember that the time you take is in the best interest of the outcome you seek.

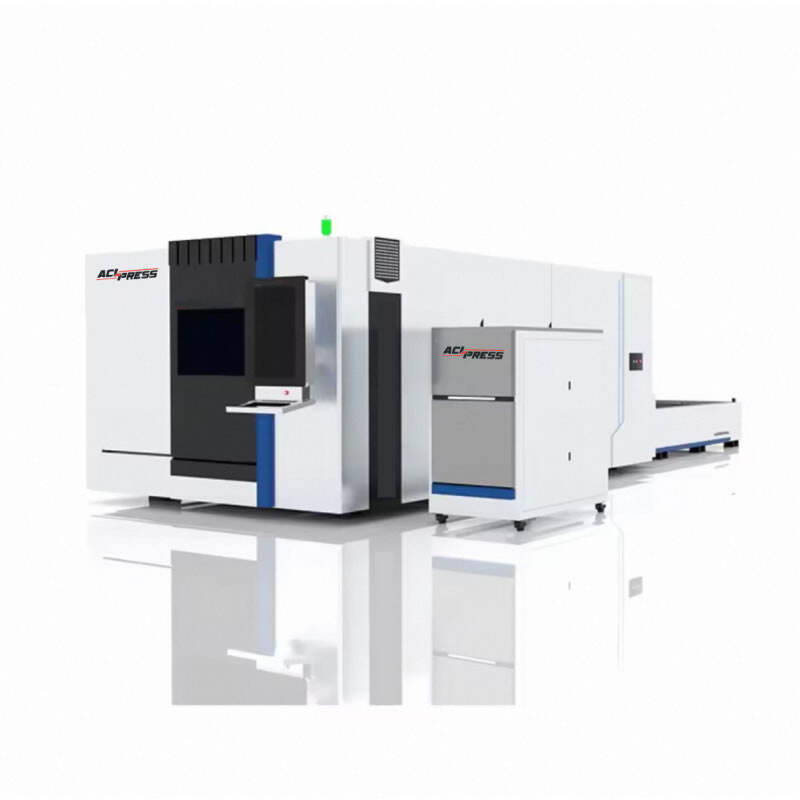

ACLPRESS rolling bending not only an extensive range of high-precision equipment for the processing of press brakes but also various precision inspection tools to identify product issues, ensuring product quality and stability. We also offer a comprehensive after-sales service.

ACLPRESS has been actively involved in the rolling bending industry for more than 20 years. We have a wealth of experience in sales and production, and can help customers address and resolve problems for a variety of product applications. Our dedicated technical team provides all-hours technical support to ensure speedy and quality service delivery.

ACLPRESS boasts a robust production capacity includes numerous CNC machine tools including a CNC Gantry machining centre CNC 4 axis machining centers and CNC precise grinding machines. Additionally it a heat treatment workshop to handle various spare parts swiftly and precisely. It also houses a rolling bending center makes sure orders from customers are processed in time and accurately.

ACLPRESS is a leader in the processing of products and modifying them. ACLPRESS is well-versed in the particulars of sheet metal bent, which allows it to offer customers the best solutions based on their production drawings, rolling bending, and conditions.