If you are not truly familiar with what a sheet metal bending dies is, let me enlighten the rest! Many industries heavily rely on the machine to create metal-based products. Someday you must have come across a car, or maybe even a bicycle to which were made via the metal press machine. This unique device is capable of making the metal bend, twist and shape into different forms for many other products. They are manufactured by a company named ACL Metal press machines are their strengths of products Metal Press Machine: the way it works and why manufacturers need to use themPlugin Lets find out more about these work champions of metallic elements.

A metal press machine is a heavy duty, durable device that manufactures tools and equipment from the basic elements [] []. It is constructed from various parts among which are its frames, ram and die. All three components have their part to play in the metal forming process. In your injection moulding machine, the frame is what holds everything together and the die – which was around 6 months in development at Protolabs before a good first article was produced-is just a fancy way of saying fork which for example helps you to create that smiley face shape. Metal is put on top of the die, and then a ram forcefully shapes it. A large number of shapes are available to form using alternate dies with this setup, and it's beneficial because metal products can cover many different designs. Metal press metal machines are used anywhere and everywhere in tons of industries like car manufacturing, airplane building, construction. They are responsible for making everything from little parts to more significant components.

Metal Press MachineThere are a lot of reasons why firms chose to employ the press brake within their production demands, Well, such devices offer highly precise and accurate manufacturing that is one of the primary reasons behind their popularity. Parts with intricate shape requirement fitting precisely into one another can be effortlessly provided by a metal press machine. This results in perfect fitting parts, which of course saves time and money. If you are precise in the way parts area made, there will be less post-cutting or extra fixing needed. Moreover, the metal press machines even can be pre-programmed to make thousands of the same form consecutively. This feature is fantastic because it can produce many parts in a short time, speeding up the production process.

Several benefits make the manufacturing procedure easier when conducted with a metal press machine. First, it saves a lot of time and prevent wastage. Rather than returning a metal back to the press several times for cutting and forming, a single machine will cut it in one process. This humanity results in quicker time to production and less scrap metal. This is the waste left over from metal, and virtually no waste product of industry benefits a company with excess useless material to dispose of; thus less scrap amounts mean both good for enterprise as well as bulk around. Further, metal press machines produce components in a variety of shapes and features at the same time. As a result, producers can create more sophisticated productsive without needing to spend additional time assembling everything later.

Manufacturing with a metal press machine has several advantages. Prior to that, however, one of the benefits is it can ultimately help in having cost effective parts being produced. Metal press machines are time and labor saving machines made specially to shape metal in the desired form. This lower costs of production for companies. Furthermore, the use of metal pressing machine will also help minimize the generation of scrap metal. This saves on the cost of materials as well as reducing environmental damage that comes from manufacturing. Lastly, the quality of part developed can be enhanced using metal press machines. Due to their incredible precision, the parts are manufactured at a steady pace and with upmost accuracy thus producing through most high-quality output product that can deliver what consumers require out of them.

This is because metal press machine allows the factory to maximise their output and minimise waste. The speed at which these machines can turn out a high number of parts in speedy manner. Higher production rate results in quicker lead times, meaning companies have the products they need faster. Moreover, metal press machines can be programmed to make other parts as well that makes it easy for manufacturers changeover. Here its flexibility helps in reducing downtime which is the time when machines are not producing anything; Finally, using metal press machine can significantly reduce waste. A metal press machine tends to produce much less waste than traditional manufacturing processes that involve additional machining and assembly periods. Not only that can save money but also help our environment.

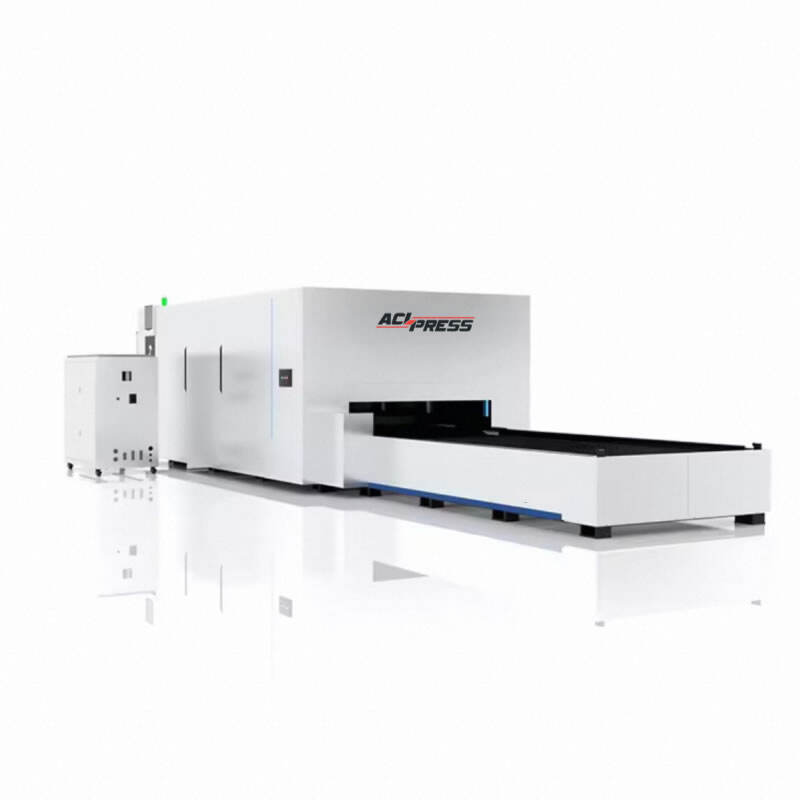

ACLPRESS possesses not only the most extensive selection of precision equipment for processing presses but also numerous precision inspecting tools to spot product issues, ensuring metal press machine and stability. In addition, we provide comprehensive service after-sales.

ACLPRESS boasts a large production capacity with numerous CNC machine tools including a CNC Gantry machining center CNC four-axis machining centers and CNC precise grinding machines. Additionally it a metal press machine workshop to treat various spare parts quickly and accurately. Furthermore it houses a debugging centre is specifically designed to ensure fulfillment of orders from customers and the precise fulfillment of their requirements.

ACLPRESS has been active in the steel metal bending industry for over 20 years. We have metal press machine in sales and production, and we can assist customers in addressing and solve issues in numerous product types. Our team of experts provides round-the clock technical support 7/24 to ensure speedy and high quality service delivery.

ACLPRESS possesses exceptional processing and the ability to customize products. It is proficient in the specifics of the metal press machine that allows it to offer customers optimal solutions built on production drawings or specifications as well as actual conditions to help them achieve meeting their goals in business.