When was the last time you wondered how metal objects are created? It’s pretty interesting! A sheet metal bending dies is used to create many of the things we see made of metal. It is very useful tool as it enables us to accurately bend metal in a solid manner. Metal bender takes metal bars, rods and sheets and bends into different shapes and angles. For this reason, it is a very adept tool in a variety of jobs. Metal benders work with everything from house construction and machine engineering, to beautiful art.

This is because a metal bender can be able to do artistic custom designs. Metal is also the medium of choice for many artists and sculptures. Artists use a metal bender to make complex and beautiful shapes, which tend to draw people's eyes to them. Since the machine is quite precise, this enables the machine to produce detailed design that would be very difficult to produce manually. Artists with concepts that may never be seen using traditional methods can be expressed in fantastic fashion and the creative capabilities when working with metal are virtually limitless.

They can take it to a whole new level and become carpenders or engineers and a press brake is a must-have for them. It allows them to build specialized metal designs, whether it be bridges that link areas, skyscrapers where people dwell and toil, and even various kinds of automobiles that patrol their roads. Accurate metal bending and formation is essential to the safety of such structures. When building stuff, safety is a big thing, and a metal bender ensures that a project will function properly after it is all said and done.

Additionally, a metal bender is also quite versatile which means a lot of different jobs can be done with it. It is capable of bending, twisting and shaping multiple forms of metal with ease. This ties in strong metals like steel, lightweight metals like aluminum and even copper, which is frequently used in wiring. The type of metals that you can work are really nice, it means that a metal bender can be used for many purposes. Additionally, it’s made to be user-friendly, allowing beginners or those with little knowledge to figure out quickly and safely how to use it.

It really helped me develop different types of inventive designs.'' There are just so many things that can be made with this tool! You can create something like a custom metal sign for a business to attract customers, or a special frame for a motorcycle — a metal bender can help you do just that. It really is a creativity and inspiration tool. Beyond that, your imagination is the limit, and a metal bender is able to turn that imaginative idea into a metal reality.

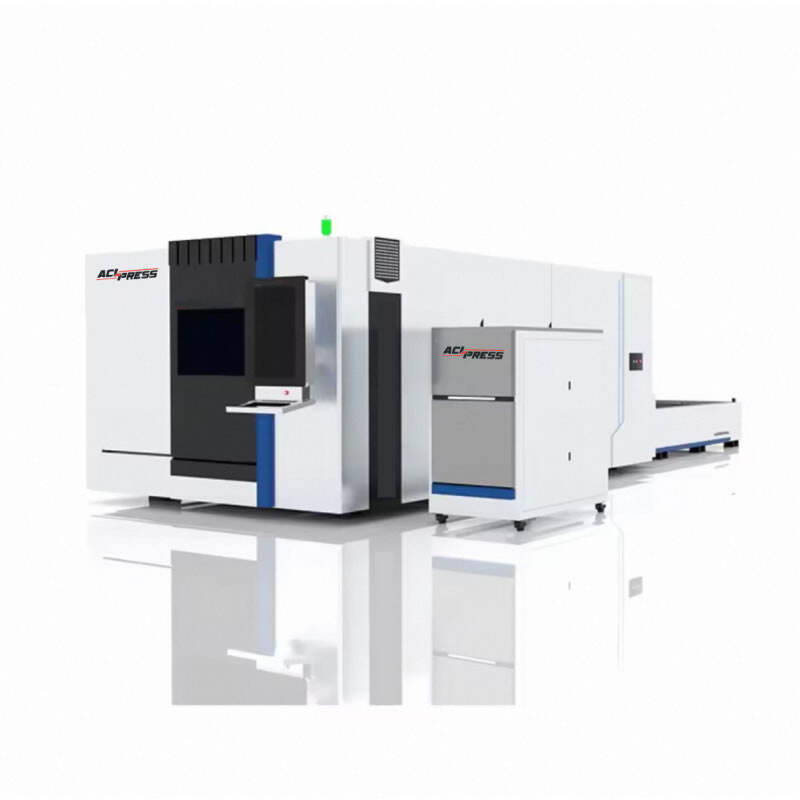

With metal benders, ACL is truly the ultimate or ideal choice. That's why our metal benders are precisely and powerfully engineered. They are forged with luxurious materials, so they are durable for years even with frequent usage. No matter if you are an engineer who needs to create strong structures, an artist looking to make beautiful sculptures, or a metalworker who loves to build things, our metal benders are sure to cater to your needs and help you succeed in your projects.

ACLPRESS is actively metal bender in the steel metal bending industry for more than 20 years. With a wealth of sales and production experience, we can aid our customers in resolving problems across a variety of applications for our products. Our dedicated technical team provides all-hours technical support to ensure quick and high quality service delivery.

ACLPRESS is a leader in the processing of products and modifying them. ACLPRESS is well-versed in the particulars of sheet metal bent, which allows it to offer customers the best solutions based on their production drawings, metal bender, and conditions.

ACLPRESS metal bender not only an extensive range of high-precision equipment for the processing of press brakes but also various precision inspection tools to identify product issues, ensuring product quality and stability. We also offer a comprehensive after-sales service.

ACLPRESS boasts a metal bender capability which includes a wide range of CNC machine tools such as a CNC Gantry machining center CNC 4-axis machining centers as well as CNC precision grinding machines Additionally it a heat treatment workshop processes various spare parts quickly and accurately In addition it houses a debugging centre is specifically designed to ensure the completion of customer orders as well as the precise fulfillment of their requirements