Iron worker is a special tool that converts steel into many structures. It is very useful for civil engineering works such as construction of buildings, bridges and other structures. The work is never the same, as press brakes come and change how we can use steel. They provided the process up to date with necklaces lowering is necessary regarding producing steel through high quality products. These high powered machines are often made by reputable companies such as ACL, which ensures that the best tools for those working in this industry are always being developed.

Steel is strong and long-lasting material which keeps buildings safe. Previously, workers were forced to manually cut, shape and fabricate steel which was a very slow and tough task. Note that this process was typically labor-intensive; it took a lot of workers to perform, which made the job long and exhausting. But now this are was long gone mow with the inexepensive iron worker machines. These beasts of machines are capable to punching holes, creating steel into the correct sizes or bending it with no problems for building purposes. This saves quite a bit of time an cuts down on the labor needed for each job.

Iron worker machines are used for various tasks and they play a very important role in the steel industry. F The ability to handle a variety of materials, including thick steel plates and angles and channels As an industry leader in the production of these machines, we ensure ours are able to complete a variety of job types quickly and efficiently. For people who work with steel, they are a valuable investment that can be used in nearly any of your projects.

These machines are precise and fast brake press. Being a machine they can execute various works consisting of hole punching, cutting, bending and notching at steel pieces. Every aspect of this plant is automated with the latest technology in ACL's machines to see that every task should be error-free. This allows every piece of steel to be cut and shaped precisely in a way that makes the process more predictable, which results in faster construction. In this case, workers can actually trust these machines to provide them with the best finished product every time.

Iron worker machines are incredibly versatile. For instance, it is possible to punch holes and cut steel using the machines while also bending steel plates so they have a shape allowing them to be used in buildings. They are even able to work with other materials, most notably aluminum and copper so they can be used in more than just steel projects ACL offers a range of iron worker machines that are versatile and designed to do it all for any steel fabrication application.

The iron worker machines made by ACL are some of the best in steel fabrication due to their smart technology combined with creative design features. They have specialized tools which assist the workers in making precise cuts at appropriate angles, every time. The machines are also very easy for operators with user-friendly controls to run so that they do not have any problem. Equally important is Safety – and these machines are equipped with functions that protect the worker during their usage. That not only makes them effective but also safe for any steel job.

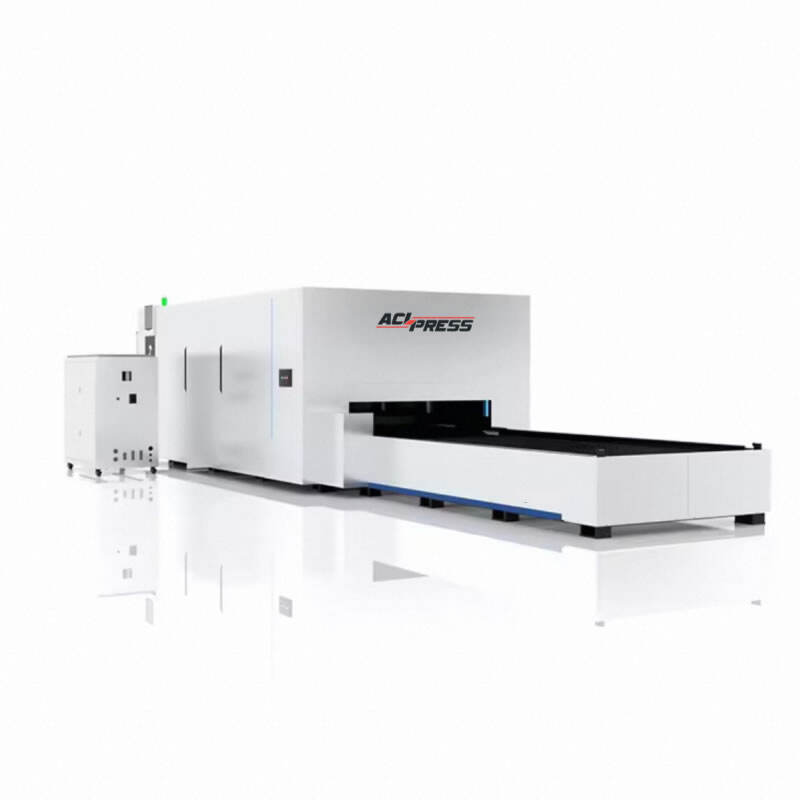

ACLPRESS has an exceptional capability in the processing of products and modifying them. It is iron worker machine in the particulars of the sheet metal bending sector, enabling it to offer customers the most efficient solutions, based on production drawings or specifications as well as actual circumstances to help them in meeting their goals in business.

ACLPRESS boasts a significant production capacity due to its CNC machines like a CNC Gantry Machine CNC 4-axis machines and CNC precision grinders It also operates the heat treatment workshop which can process iron worker machine fast and precisely In addition it houses a debugging centre is specifically designed to ensure prompt completion of customer orders and the exact fulfillment of their needs.

ACLPRESS iron worker machine not only an extensive range of high-precision equipment for the processing of press brakes but also various precision inspection tools to identify product issues, ensuring product quality and stability. We also offer a comprehensive after-sales service.

ACLPRESS has been active in the steel metal bending industry for over 20 years. We have iron worker machine in sales and production, and we can assist customers in addressing and solve issues in numerous product types. Our team of experts provides round-the clock technical support 7/24 to ensure speedy and high quality service delivery.