Bending equipment is a type of machine that we use to create new shapes out of different materials. This machine are present in most of the factories incubate to numerous types of products. There are many different types of pressing and bending, and all help workers to get their jobs done faster with a great deal more ease. This equipment allows factories to produce many things in an shorter period of time.

It doesn't matter what type of bending equipment you use, they all have similar working principles on how to bend something into a shape, even if they appear to be different sized or differently styled. Multiple types including manual, hydraulic, and CNC bending machines.

CNC bending machines are extremely advanced. These machines can execute instructions from a computer program to make precise shapes. This allows them to create the same shape repeatedly, with perfect accuracy, a very common need for factories requiring numerous identical components.

So the bending factories usually have press brake bending which makes the work very convenient for the factory men. They can create shapes more quickly and precisely with this equipment. Rather than spending a long time making one such shape by hand, workers can now use machines to achieve that in a tiny percentage of the time. This means factories can make more items in less time. Faster production is beneficial too since that allows workers to produce other items enabling the factory to remain operational.

Mini bending machines are specialized for small items such as jewelry. These are smaller machines that bend metal into basic shapes — circles, squares, triangles. It is quite useful for designing unique and beautiful items of jewelry. These machines speed up the making of the processes instead of making everything by hand, which can take a good amount of time. This allows for numerous designs to be crafted without dedicating too much time to each.

Bending equipment is also applicable to materials other than metals. It molds materials such as plastic, rubber and even certain varieties of wood. This flexibility gives factories the flexibility to make a range of products. Such as using plastic bending machines to produce components of toys or containers. Factories adjust to these modifiers while using bending devices for various materials, so they make numerous items and can satisfy their customers.

When using bending equipment, it is extremely necessary to use cutting-edge technology. Newer machines are engineered to make the shaping process safer and simpler for workers. The newest technology is incorporated into ACL's bending equipment, which allows for faster and safer shaping of metal. This allows workers to produce more goods in a shorter time and lower the risk of accidents. Modern machines have safety features that can offer protection to their operators, thus making the workplace safer.

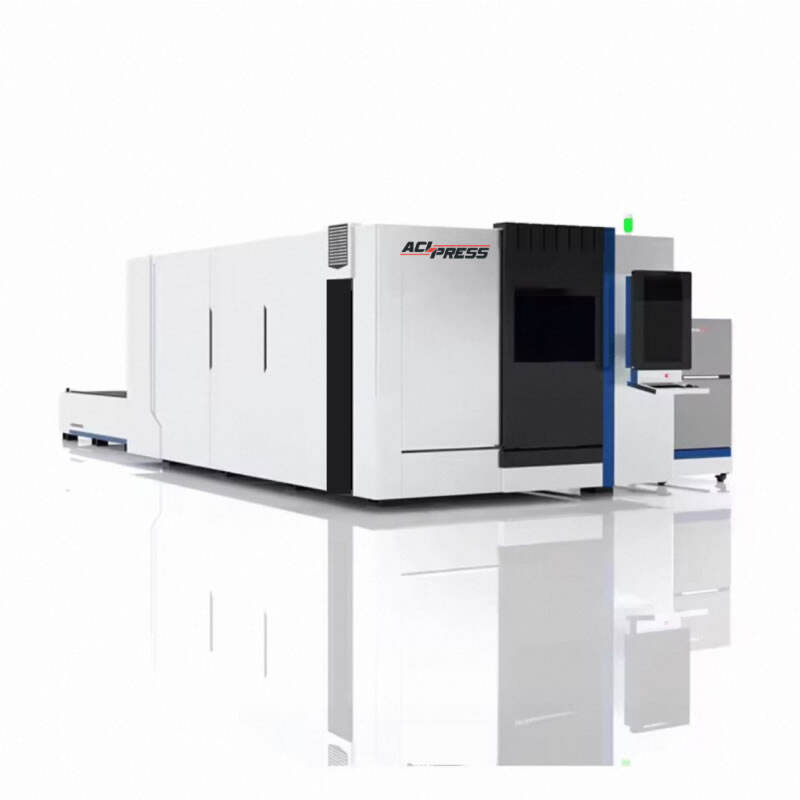

ACLPRESS is a bending equipment for processing and customizing products. It is knowledgeable about the particulars of the sheet metal bending industry, enabling it to offer customers the most efficient solutions, based on production drawings, requirements, and actual conditions to help them achieve reaching their business objectives.

ACLPRESS boasts a significant production capacity due to its CNC machines like a CNC Gantry Machine CNC 4-axis machines and CNC precision grinders It also operates the heat treatment workshop which can process various spare parts fast and precisely In addition it houses a debugging centre that is specifically designed to ensure prompt completion of customer orders and the bending equipment of their needs

ACLPRESS is actively involved in the field of steel bending for over 20 years. With bending equipment and sales knowledge, we can help our customers in resolving problems in a range of applications for our products. Furthermore, our technical staff provides 24/7 technical support, seven days a week, ensuring prompt and high-quality support to our customers.

ACLPRESS offers not just the most extensive selection of precision equipment for the processing of press brakes but also numerous precision inspecting tools to spot issues with products, bending equipment durability and reliability. In addition, we provide comprehensive after-sales service.