Bending steel sheets requires the right tools and care. The press break steel is one of those critical tools. With this machine you can cut sharp 90-degree angles, curves and all kinds of other shapes. The steel sheet bender has revolutionized the industry by moving quickly and accurately through the steel sheet molding process.

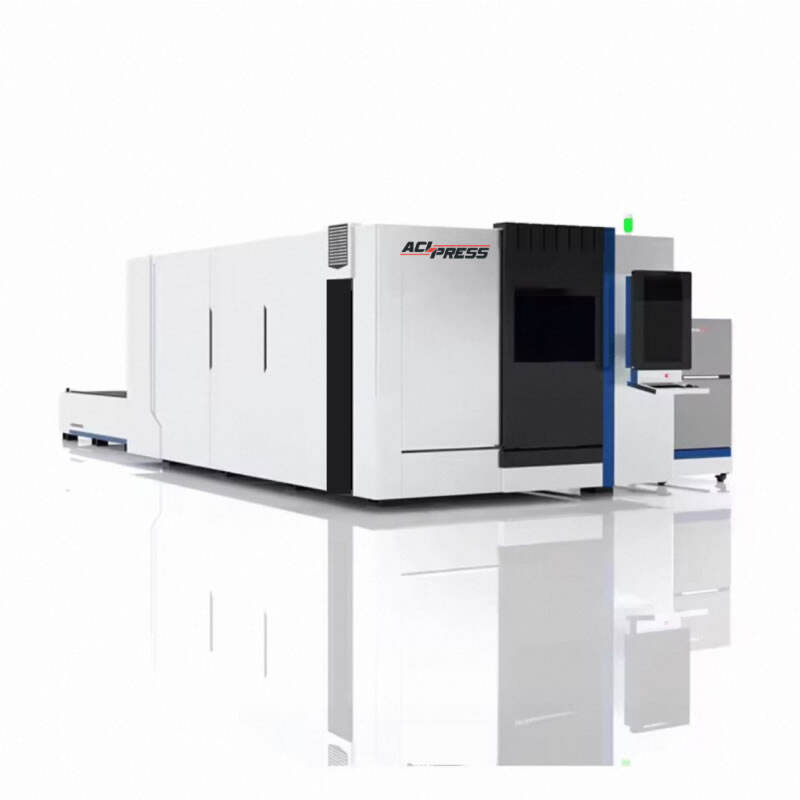

Steel is a great material, and a very useful material, but it must be worked by the right person using the right tools. ACL produces some of the best sheet bending machines that help industries to convert steel into different forms. These machines are capable of producing everything from metal roofs, to car parts, and everything in between. Sheet bending can make nearly limitless products!

Additionally bending steel makes it possible to produce strong products, but it gives a wider room for design as well. Industries can design custom forms to fit their needs and the demands of their customers. This allows businesses to differentiate themselves and become more competitive in the market.

Depending on your need to bend steel sheet, there are various ready-made forms to use, but they all work best in certain circumstances. One common tactic is known as air bending. In this technique, the sheet is shaped into the desired shape, with the assistance of a punch and die. Another great aspect of this technique is that you can have very precise bends and will not damage the material.

A second method is known as bottom bending. This process utilizes a V-shaped die to produce a waistline in the sheet. It is essential to know these different bending methods, as it enables respective industries to select the best for their specific requirements. More techniques will yield varying results, and understanding which to utilize is often the difference between mediocrity and exceptional outcomes in the end product.

ACL springs, press brakes are made to benefit industries a globe in every place. They can bend sheets of steel as thick as 12mm! And that means they’re good at some really hard work. Whatever your profession, be it construction, auto manufacturing, or a product manufacturer, the ACL steel sheet bender is a tool you can depend on to make your work easier and faster.

There are many ways in which these machines can help to increase productivity. Empowering Workers with the Right Tools for Faster, More Accurate Completion of Tasks. Not only that, it also saves time, but, with it the waste of materials and money, increasing the efficiency of businesses as a whole.

ACLPRESS has an exceptional capability in the processing of products and modifying them. It is steel sheet bender in the particulars of the sheet metal bending sector, enabling it to offer customers the most efficient solutions, based on production drawings or specifications as well as actual circumstances to help them in meeting their goals in business.

ACLPRESS is actively involved in the field of steel bending for over 20 years. With steel sheet bender and sales knowledge, we can help our customers in resolving problems in a range of applications for our products. Furthermore, our technical staff provides 24/7 technical support, seven days a week, ensuring prompt and high-quality support to our customers.

steel sheet bender a large production capacity thanks to its CNC machines like a CNC Gantry Machine CNC 4-axis machines and CNC precision grinders. Moreover it operates its heat treatment workshop can treat various spare parts quickly and accurately. It also houses a debugging center makes sure the orders of customers are fulfilled punctually and accurately.

ACLPRESS has a large range of high-precision equipment that can process steel sheet bender, as well with a range of inspection tools that find problems with the product and ensure its reliability. Additionally, we offer comprehensive after-sales support.