Now, press brake means, a device used for joining a rivet and two parts of similar or different types. Have you seen a rivet before? It is a small bulb of metal that connects two pieces of things (such as metal or fabric). Let us say you have two pieces of metal that you need to bond together. But how does a rivet run, in general? The correct procedure: The rivet is inserted into the hole and the bulb end of the rivet is bucked against from the other side. This compresses the metal bulb so it cannot return to the outside. Now the two pieces are glued together pretty tightly and securely!

So, what does a riveting machine do? This makes it easier and faster to do in big factories that have a lot of things to be joined in a short period of time. The machine allows for the use of various kinds of materials — metal, fabric, or plastic — to complete multiple rivets at once rather than one at a time as would be the case if done all by hand. This greatly reduced the turnaround time and allowed products to be created much faster.

Let’s recall a few examples of how many things in our world are made of many parts, whether they’re all joined together with rivets. That will tell us why brake presss are significant! Consider cars, planes, toys, furniture, and even clothes. Rivets can be used to make all of these items stronger and more reliable than weaker methods (such as glue or stitching) can. They form a very tight bond that allows the items to survive.

It also facilitates collaboration among people working on large projects. Instead of having one person hold a rivet in place while another hits it with a hammer to make it stay, the machine can do both jobs at once. This means less work for humans, but it’s also less strenuous on their arms and hands. This reduces the risk of injury during work, which is critical in heavy jobs.

One machine type, for instance, employs a hammer to punch the rivets through the two pieces to join. For some materials, that hammering action is very effective. Another kind of rivet, for which you employ a punch, and anvil with which to shape the rivet. This approach can be extremely accurate however is utilized for more complex patterns. More modern machines use advanced methods to bind parts together like sound waves or heat. There exist compact handheld riveting guns for fast jobs that can be completed by only a single person. Each machine has its strengths and shortcomings, depending on the needs of the job.

Strong Hold: Riveting makes a strong connection that won’t fall apart easily, as sewn or glued items might. If two pieces of metal are riveted together, they won’t vibrate apart over time the way pieces held together with glue might. — which is important with stuff that is supposed to last a while, airplanes or bridges and what not.

ACL needs many different types of machines that work with a variety of different materials, make different types of rivets. The variety allows them to cater to the needs of many customers — whether they are producing cars, furniture or even toys. Acl can allow more companies to make strong, durable products that can be made quickly by providing good easy-to-use riveting machines.

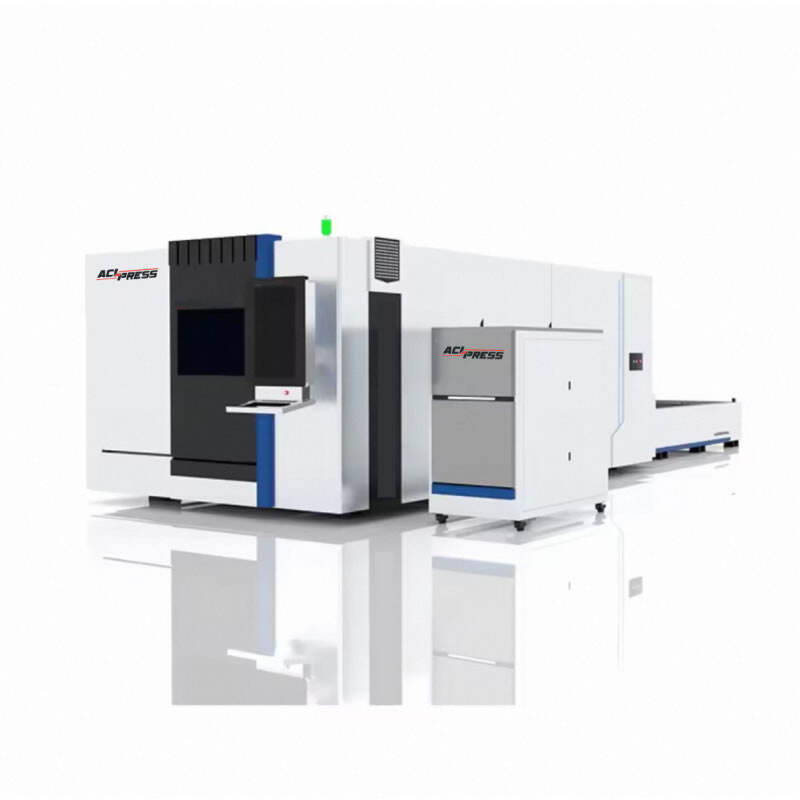

ACLPRESS offers not just the most extensive selection of precision equipment for the processing of press brakes but also numerous precision inspecting tools to spot issues with products, riveting machine durability and reliability. In addition, we provide comprehensive after-sales service.

riveting machine a large production capacity thanks to its CNC machines like a CNC Gantry Machine CNC 4-axis machines and CNC precision grinders. Moreover it operates its heat treatment workshop can treat various spare parts quickly and accurately. It also houses a debugging center makes sure the orders of customers are fulfilled punctually and accurately.

ACLPRESS is a leader for processing and customizing products. It is proficient in the specifics of the bending of sheet metal and can offer customers the most efficient solutions, built on production drawings as well as requirements and conditions to assist them in reaching their riveting machine.

ACLPRESS has been active in the steel metal bending industry for over 20 years. We have riveting machine in sales and production, and we can assist customers in addressing and solve issues in numerous product types. Our team of experts provides round-the clock technical support 7/24 to ensure speedy and high quality service delivery.