We will cover the subject of press brake, which is a subject that you need to study if you plan to cut perfect shapes and designs from metal. Profile cutting is an advanced process, which is used to cut sheets of metal to various shapes using sophisticated machines. At ACL, we excel at profile cutting, so your projects are created to your specifications.

We do a lot of laser cutting at ACL, a great technology that delivers wonderful shapes for our customers. Laser cutting machines use powerful beams of light. Technologies like these beams melt and vaporize metal sheets, making very precise cuts possible. This means we get to make some dope shapes and designs that are cool. Laser cutting technology allows us to easily and precisely complete even the most intricate designs.

We know that each business is different and that each metal project has unique requirements. This is why we provide bespoke wood cutting solutions specifically to your organisation. With the help of our skilled engineers and technicians, we’ll ensure that your metal fabrication work is tailored to your specifications. Instead, you can focus on other things, while we ensure your projects are completed on time and within budget.

Diverse applications require different levels of processing techniques for metal projects to meet high standards. All the ACL topics are familiar with recent technologies and trends, which is why you get good quality after such extensive work done. Whatever specific shapes or very complex designs that you would need, we will have the necessary instruments and the know-how to ensure you are satisfied with the output.

With ACL and our advanced cutting techniques, you can rest assured that no shape or design is too hard to tackle. With years of experience in metal fabrication projects of varying sizes and complexities, our highly-trained specialists are ready to assist with yours. We know how to make your ideas a reality, whether you require acute angles, tight curves, or decorative patterns. We have what it takes to get the results you need.

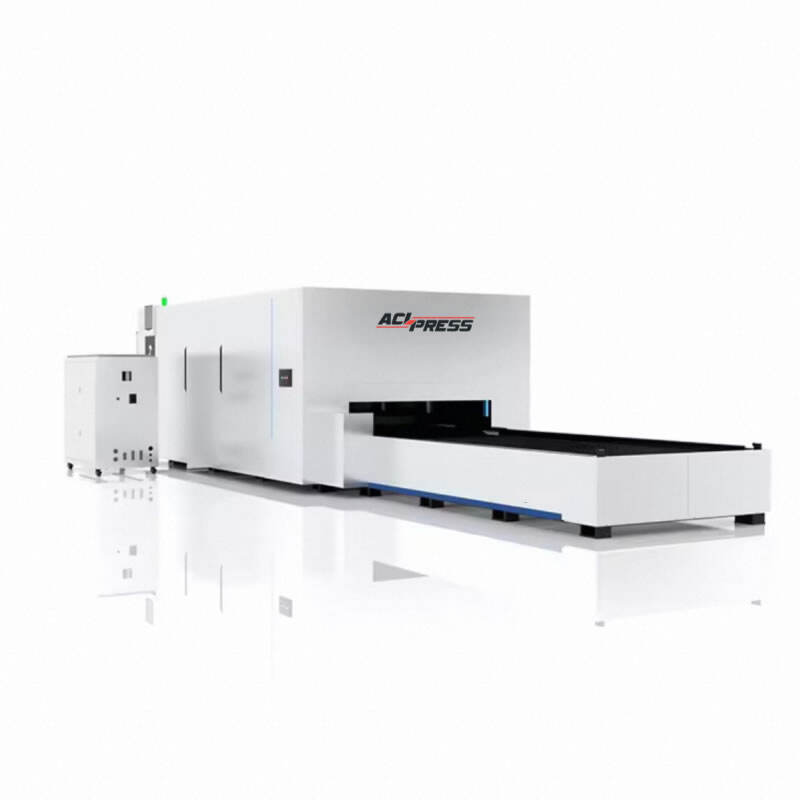

ACLPRESS is actively profile cutting in the steel metal bending industry for more than 20 years. With a wealth of sales and production experience, we can aid our customers in resolving problems across a variety of applications for our products. Our dedicated technical team provides all-hours technical support to ensure quick and high quality service delivery.

ACLPRESS is a profile cutting for processing and customizing products. It is knowledgeable about the particulars of the sheet metal bending industry, enabling it to offer customers the most efficient solutions, based on production drawings, requirements, and actual conditions to help them achieve reaching their business objectives.

ACLPRESS is not just home to the profile cutting of precision equipment for the processing of press brakes but also various precision inspecting tools to spot defects in the product, and ensure reliability and stability. We also offer a comprehensive after-sales support.

ACLPRESS boasts a robust production capacity includes numerous CNC machines which include a profile cutting CNC four-axis machining centers as well as CNC precise grinding machines. ACLPRESS also an industrial heat treatment facility treats various spare parts swiftly and precisely. It also houses an individual debugging center is designed to ensure fulfillment of customer requests and precise fulfillment of their requirements.