Hello boys and girls! For the coming day, we will discover fully what press brake are, and how they serve factories. Production machines are where factories build everything from toys to clothing to food. Essentially, these machines are the very pinnacle of rapid manufacturing technology. That means, we can build more products in less time, which is great for all of us!

Working at a company called ACL — where we design and build all sorts of production machines to help factories run in a fast and easy way. Our machines are built to speed up the production process and thus save time and money for factories. But when factories can save time, they can produce more products and serve more customers. And that is the reason our machines are a big help!

The one good thing about our prod machines is they are so powerful. Power, when used in relation to a machine, means the machine does work within short time frames. It is crucial as factories with machines can deliver a lot of products faster. That means that if a factory wants to produce 100 toys, a big machinery can assist them to produce that a lot faster than in case that every one work done manually.

We also enhance brake press with smart technology at ACL. You are probably asking yourself what does smart technology mean? Basically, smart technology is about implementing computers, sensors, and other data processing units to make machines serve basically more efficiently. These technologies help our machines understand what they are supposed to do, so they can do their best work.

Our production machines have another great feature; they are automated. This indicates that these machines can actually operate on their own and do not require human assistance at all times. Isn’t that amazing? As the machines are capable of working without assistance, factories can create produce with less people needing to be employed. It can save them lots of money.

Automation machines also allow manufacturers to produce more. Because the machines can operate continuously, they can produce goods more quickly than if humans were handling everything. This is absolutely critical for the manufacture of components such as automobile or electronics, which are usually very high in demand.

Finally, our production machines are extremely versatile. That means they can be used to create a wide variety of products. Factories don’t have to purchase new machines each time they want to produce something different. Like if a factory wants to stop making toys to make clothes instead, it can command the same machine to do both!

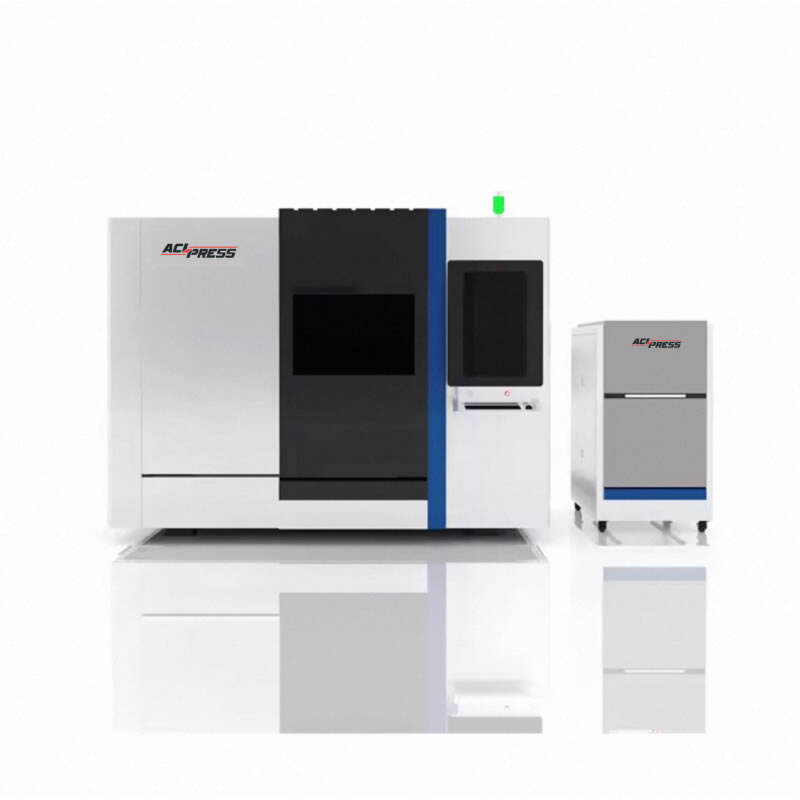

ACLPRESS has exceptional capabilities in processing and customizing products. ACLPRESS is well-versed in the particulars of sheet metal bends, which allows it to offer customers the most efficient solutions in line with their production plans production machines, requirements, and other specifications.

production machines a large production capacity thanks to its CNC machines like a CNC Gantry Machine CNC 4-axis machines and CNC precision grinders. Moreover it operates its heat treatment workshop can treat various spare parts quickly and accurately. It also houses a debugging center makes sure the orders of customers are fulfilled punctually and accurately.

ACLPRESS is involved in the steel bending business for more than 20 years. With a wealth of sales and production experience, we can assist our customers in resolving issues in a production machines of application areas. Our technical staff is available all-hours technical support to ensure prompt and top-quality service delivery.

production machines offers a wide range of precise equipment for processing press brakes as well as a variety of inspection tools that spot problems that may be affecting the product and guarantee its reliability. We also offer a comprehensive after-sales support.