Metal Working Machines are strong and useful tools that assist us in creating numerous types of metal items. If so, as per your metal related Industrial project you may require Metal Working Machines. These machines can bend, cut or shape — in a number of ways — metal using electricity or a specific type of fluid power. These tools prove to be very useful for several works in workshops and factories.

Metal Working Machines are the perfect example of how great modern technology really is. They can bend, cut, punch and form metals within tolerances of thickness and time. This allows them to make perfectly-fitting components. They can also process various metal types, including steel, aluminum, and copper. There are several kinds of machines used to make different types of metal work. For example, some machines are designed to cut, while others are designed to shape.

Metal Working Machines are essential part of our world. Many different industries need Metal Working Machines to perform their work. Factories, for instance, rely on these machines to make things as varied as parts of other machines, car components, and structural elements in metal. Without these machines, the removal of materials while shaping products would be a slower, more expensive, and less precise process. This can cause errors and material wastage. Besides, the advent of Metal Working Machines has opened new avenues for the skilled professionals capable of handling them. These machines have yet proved to be a boon to various industries alike, easing the work-load.

They can also manufacture the types of Metal Working Machines not only simple parts. They also have the ability to generate very intricate designs featuring lots of details and patterns. This is crucial for artists and sculptors who use metal. These machines can produce the precise components they require for their art, which in turn enables them to explore their creativity in innovative ways. These machines help bring an artist's vision into reality, allowing a creation that is both beautiful and complicated to become tangible through metal.

The versatility is one of the biggest advantages of Metal Working Machines. They can also be used in various sectors like automotive, construction, aerospace, or architecture. All these areas have their own needs, and there are dedicated machines for those jobs. Welding machines come in handy for joining metal parts together, and laser cutting machines are perfect for making minute cuts. This automation allows for faster jewelling and greater accuracy by using CNC machines. Lathe machines mold the metal into circular shapes. With so many different types of machines, almost any type of metalworking job has a solution.

I'm guessing that most people don't realize all the cool stuff Metal Working Machines can do. Certain machines do jobs quicker and more efficiently than others, heavily relying on what purpose they were created for. You will also find latest products and techniques in metalworking machines that represent a restructuring of the industry. One such emerging technology is fluid cell forming that enables more complex shapes and designs. The ACL company is focused on delivering customers the best in metalworking machines, tailored to their various requirements. More so than just even more dedicated ACL machines, these reward machines are big beefy beasts built for almost anything production related.

It doesn't just mean your "ordinary" home stuff or even your simple metal monotype. They stretch our own creative potential and inspire new forms. One example is in aerospace engineering, where these machines create lightweight metal pieces that can withstand the rigors of high speeds and high temperatures. This is important for building planes and spacecraft. ACL metalworking machines are also used for welding different metal parts together to generate new objects and designs. The world of metalworking has many exciting places yet to be explored.

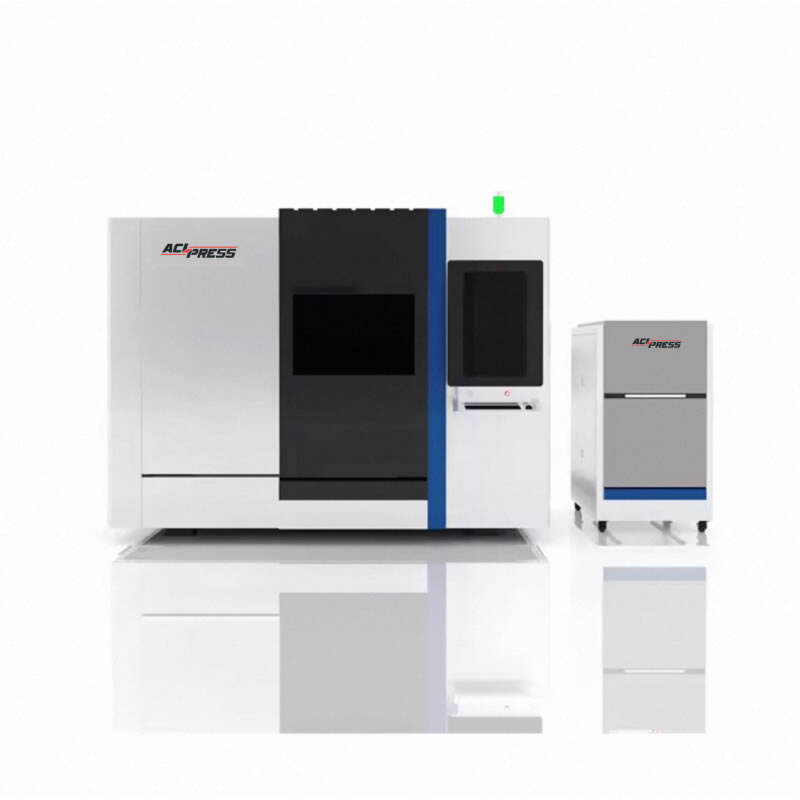

ACLPRESS boasts a robust production capacity includes numerous CNC machine tools including a CNC Gantry machining centre CNC 4 axis machining centers and CNC precise grinding machines. Additionally it a heat treatment workshop to handle various spare parts swiftly and precisely. It also houses a metal working machine center makes sure orders from customers are processed in time and accurately.

ACLPRESS is actively involved in the steel metal bending industry for more than metal working machine. With a wealth of sales and production experience, we can aid customers with resolving problems across a variety of product applications. Our team of experts provides 24 hours of technical assistance to ensure quick and high quality service delivery.

ACLPRESS is not just home to the metal working machine of precision equipment for the processing of press brakes but also various precision inspecting tools to spot defects in the product, and ensure reliability and stability. We also offer a comprehensive after-sales support.

ACLPRESS possesses exceptional processing and the ability to customize products. It is proficient in the specifics of the metal working machine that allows it to offer customers optimal solutions built on production drawings or specifications as well as actual conditions to help them achieve meeting their goals in business.