Have you ever listened to press brake, which is otherwise known as metalworking? This is a high-exactitude process which is used to cut, shape and form materials such as metal or plastic. Industrial machining is used to create new machine parts. It also seems very straightforward to accomplish at first (or at least in a video), but it does take quite a bit of skill and attention to detail to make everything come out correctly. But if the parts aren't precisely made, they don't fit together well, which can lead to issues when the machines are in operation. So, companies such as ACL are built on the most advanced technology and methodology. They produce tailored machine components that are efficient in their operation as well as safe to use.

Do you know how to play with Legos? Building a Lego tower, you have to see that those pieces fit just right. Industrial machining is like building with Legos, you must be precise and detail-oriented so each piece fits perfectly in place as you begin to build up your structure. Machines are critical; they need to be reliable; they need to deliver a perfect execution every time." A small mistake in parts keeps big problems for later in line. This is one of the reasons that ACL utilizes special digital tools like Computer Numerical Control (CNC). This technology allows us to take very precise measurements and cuts, which is essential in making the parts we require. Using CNC, it is possible to produce even complex shapes with high precision. These advanced technology and methods such as these help us to ensure that the parts we manufacture are a perfect fit for your needs.

The world is in perpetual motion, and so are the tools and machines that we use for brake press. At ACL, we think it is important to stay on top of technology that can make our work even better. For instance, 3D printing has revolutionized manufacturing. It enables us to create more flexible and detailed designs than ever before. We’re able to create components that fit better and operate better. We also use an awesome process called water jet cutting. During this process, a very high-pressure stream of water, penetrates through metals or plastics. This is a very accurate technique and produces clean edges in the components that we manufacture. We are continually learning more about every process, refining those processes and learning new ones, which are the best and most cost-effective parts that we can provide for our clients.

All machines are unique, and that necessitates that we design the parts to integrate well with the specific machine,Printing parts is only part of the solution. When you select to work with ACL you are not simply getting regular parts that anyone can buy from the shelf. You’ve gotten bespoke parts, made specifically for you. We will have our best team to understand your business, and then develop what you require. Such custom castings are designed and manufactured to deliver efficiency and reliability both in the short and long run. Custom-made parts for your machines can also save you money over time. Custom parts also last longer, meaning you won’t be replacing them as frequently.

Time is money — and that is especially true for businesses that rely on machines to accomplish work. Industrial machining helps you increase the efficiency of your operations, improve productivity. But how do we do this? We can also save downtime and maintenance costs with parts that is designed to fit your machines like a glove. Downtime refers to the time when machines are inactive, which is something very expensive for a company. A machine that is efficient not only saves you money, but it also enables you to manufacture more products in a lesser time frame. In addition, we can enhance how your machines run using intelligent software and hardware. This means we can help minimize waste in a process and maximize the usable product you receive out of your materials.

ACL is always committed to safety first. We realize how dangerous industrial machining can be if not done correctly. That is why we are observant of stringent safety protocols to ensure the safety of all parties involved. All employees receive comprehensive training in the proper use of machinery. This training is extremely vital for us, as it equips our team to operate the machines in a safe, accurate manner. We also supply protective equipment like gloves, safety goggles, and helmets to ensure our workers are safe while they are on the job. Safety is high-ground, but it also requires ensuring our machines are operating best of their capabilities. We constantly check our machines to make sure everything flies high. This is necessary for us to identify potential issues as early as possible, minimizing the risk of accidents and ensuring safety of the entire workplace.

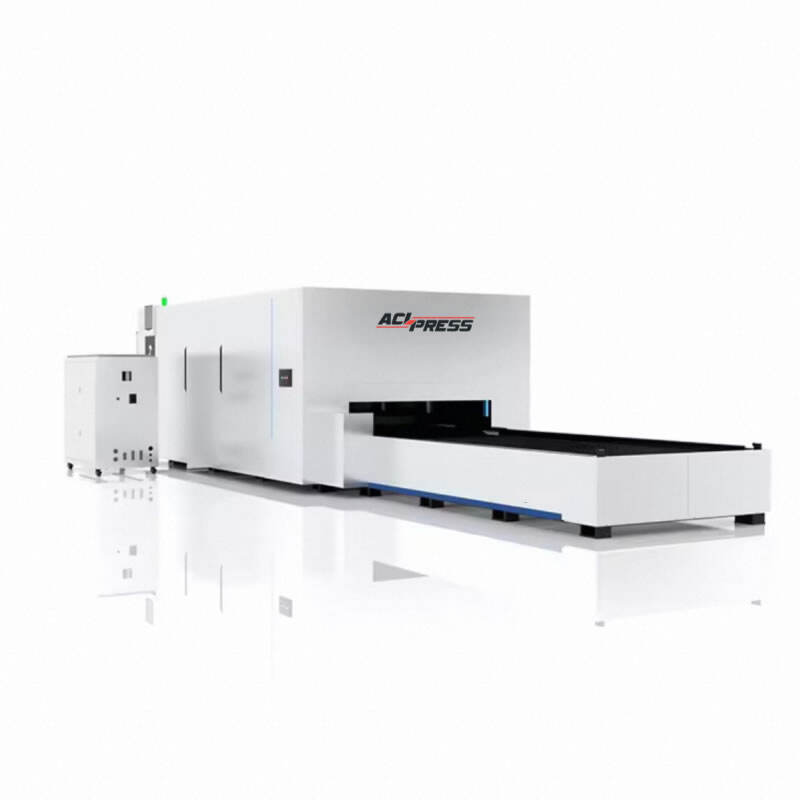

ACLPRESS industrial machining not just a wide range of precision equipment for press brake processing as well as a variety of precision inspection tools to identify defects in the product, and ensure reliability and stability. ACLPRESS also provides a complete after-sales support.

ACLPRESS is actively involved in the steel metal bending industry for more than industrial machining. With a wealth of sales and production experience, we can aid customers with resolving problems across a variety of product applications. Our team of experts provides 24 hours of technical assistance to ensure quick and high quality service delivery.

industrial machining offers exceptional processing and product customization capabilities. ACLPRESS is highly knowledgeable of the specifics of sheet metal bending, which allows it to provide customers with the most efficient solutions based on their production drawings, needs, and conditions.

ACLPRESS boasts a robust production capacity includes numerous CNC machine tools including a CNC Gantry machining centre CNC 4 axis machining centers and CNC precise grinding machines. Additionally it a heat treatment workshop to handle various spare parts swiftly and precisely. It also houses a industrial machining center makes sure orders from customers are processed in time and accurately.