How it used to be done: Crafting equipment has come a long way, fighting all that folksy homebrew invention. It used to be laborious and sometimes quite a hardship to create equipment. Today with new technology, it will be a lot easier for factories to make anything at better speed and quality. This new technology is changing the way we manufacture equipment for all involved parties and saving time.

3D Printing allows press brake to be drastically different. This incredible technology allows factories to produce parts and complete pieces of machinery rapidly. 3D printing works by building the parts up layer-by-layer instead of with a lot of different steps and machines. It takes less time to fabricate, which saves the factory money. 3D print also serves to generate personalized assemblies the customer request. If a person wants an unconventional part he can easily make it without spending much money. This was a boon for people as now they could get whatever they wanted with much ease.

The drive to use machines in the production of equipment is another significant shift. Aka automation, these machines help factories do the work faster, make things cheaper and enhance product quality. This increase productivity since factories will produce more equipment faster, and with fewer errors. These machines make it possible for workers to concentrate on other tasks that need fine tuning. That makes the whole process smoother and more efficient.

One of the popular cool materials is carbon fiber. It is lightweight, and at the same time quite strong. So people use it to things like bicycles, sports equipment and airplane parts. Carbon fiber is lighter, which helps equipment moves better closer and faster. It achieves this by making equipment operate more effectively, thereby using less energy. This is an environmentally savvy process, and it conserves resources.

One of these new materials to get a lot attention is called graphene. These stuff are highly thin and ultra thorough. It behaves in unique ways that other types of metals cannot. One such use case can be in creating lighter and faster electronics, like those present inside a smartphone with the help of graphene. Its fascinating qualities will lead to the utilization of graphene in everything from computers and airplanes in a couple years ahead.

Lean Manufacturing — One of the ways factories are moving towards this direction is by adopting lean manufacturing. Accountants are trained to do this kind of thing, which means that they would seek to reduce any factor not adding value in the production process. Factories will better run by concentrating on where they can add value and cutting out the wastefulness. This way it cuts cost for them and the customers are happy since they get their products sooner.

This has led companies to roll out new environmentally-friendly materials and technology. They are trying to minimize waste and recycle even further. Less is more for the planet: By getting better at making things, we can make them with fewer resources and a smaller impact on earth. And such sustainability is not just good for the environment but also helps companies stay profitable in long-term.

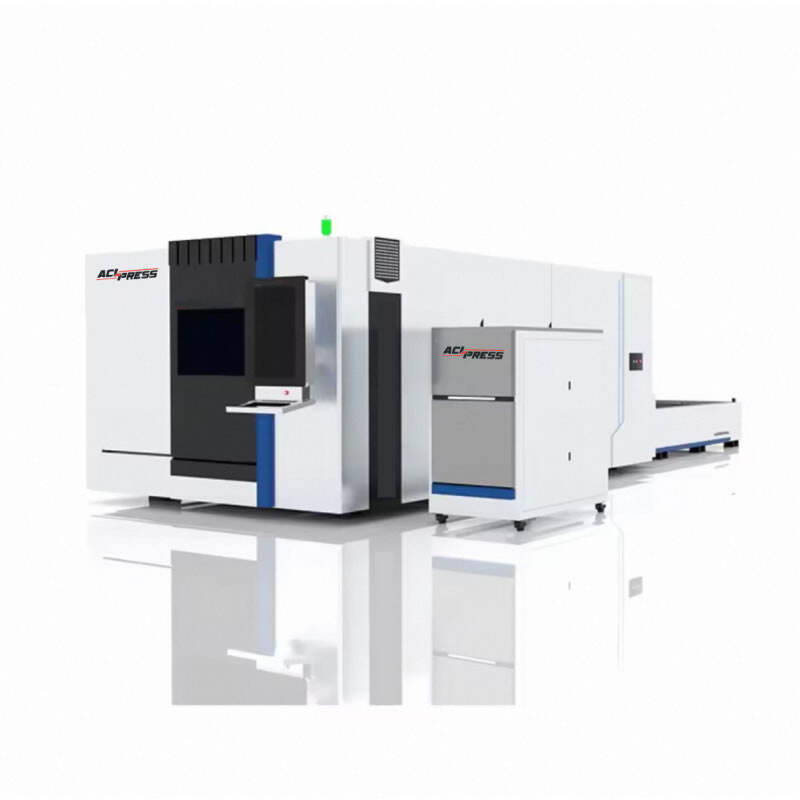

ACLPRESS equipment manufacturing not just a wide range of precision equipment for press brake processing as well as a variety of precision inspection tools to identify defects in the product, and ensure reliability and stability. ACLPRESS also provides a complete after-sales support.

ACLPRESS has exceptional capabilities in processing and customizing products. ACLPRESS is well-versed in the particulars of sheet metal bends, which allows it to offer customers the most efficient solutions in line with their production plans equipment manufacturing, requirements, and other specifications.

ACLPRESS equipment manufacturing a robust production capacity with numerous CNC machines which include a CNC Gantry machining centre CNC four-axis machining centers and CNC precise grinding machines. It also operates a heat treatment workshop treats various spare parts swiftly and precisely. It also a debugging centre to ensure the orders of customers are fulfilled punctually and accurately.

ACLPRESS has been actively involved in the equipment manufacturing industry for more than 20 years. We have a wealth of experience in sales and production, and can help customers address and resolve problems for a variety of product applications. Our dedicated technical team provides all-hours technical support to ensure speedy and quality service delivery.