A brake die is a special tool that factories use to reshape sheet metal. It is a very important tool for all of us because it shows us how many of the things we see every day, such as cars, airplanes, and buildings, were made. When bending or shaping a metal, we use a brake die. It is hooked to a machine known as a press brake. The machine does so by putting pressure down onto the die that bends the metal into the shape that we want. Brake dies can all be relatively different in construction, as the forms we can create are linked to how the brake die is made.

Apply Lubrication: Lubrication is another key to maintaining press brake. It aids in keeping the surface of the die smooth. And if the surface is not smooth enough, you may find it more difficult to bend the metal, and it may not bend accurately. This can result in errors and those errors can be more expensive to rectify. So, using lubrication on a regular basis the ensures smooth operation.

PROBLEM #1: Bending or Cracking: One of the most serious problems that can occur is if the brake be die that bends or cracks. In other words, the die will have malfunctioned. If you see a crack or bend, you should replace the damaged die immediately. Be sure to check the machine settings for pressure and speed to ensure they are correct as well. Those settings can be configured to extend the life of the new die.

Another one of the problems is uneven wear. A brake die not rotated regular enough will wear out on one side faster than the other. This uneven wear can cause the metal to flex in the wrong direction. This can be remedied by rotating the brake die at regular intervals. You may also wish to include a backup die. An extra die can be helpful as well in long term maintenance and can save time in busy production.

Warping: Brake dies can sometimes warp, meaning they bend. This generally occurs when they overheat, especially if they are constructed from lesser-grade steel. After a period of use, if the brake die warps, and needs to be cooled down slowly. The cooling program of the press brake machine can reduce the temperature slowly so that the die can be restored to its original shape.

When choosing a brake die for a particular job, make sure to take the manufacturer's specs into account. Consider the thickness of the sheet metal, the geometry that you want to produce, and how much the machine can handle for each operation. This is a critical process because different materials will require different types of brake dies, and also because brake dies are single-use meaning the right die must be matched with the job at hand. Training on data until October 2023 makes things easier.

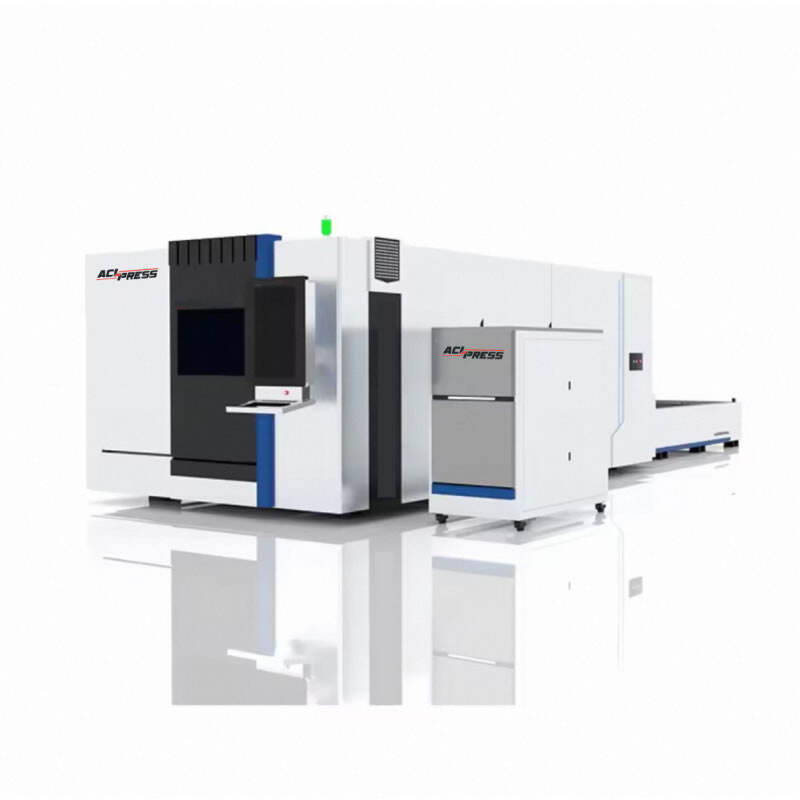

Accessory Componentry Limited (ACL): ACL is dedicated to the production of top-of-the-line brake dies across various sectors. After many years, we wish our dies developed to be strong, long-lasting reliable, with little maintenance required. Contact us to learn more about our brake dies and how they can be the right fit for you. Diagnosing and solving your metalworking needs is what we do best!

ACLPRESS has been active in the industry of steel metal bending for over 20 years. We have a wealth of experience in sales and production, and we can assist customers in addressing and solve issues in a variety of product applications. Our skilled technical team offers round-the clock technical support brake dies to ensure timely and efficient service delivery.

ACLPRESS possesses not only the most extensive selection of precision equipment for processing presses but also numerous precision inspecting tools to spot product issues, ensuring brake dies and stability. In addition, we provide comprehensive service after-sales.

ACLPRESS brake dies exceptional processing and capability to customise products. It is well-versed in the specifics of the bending of sheet metal which allows it to provide customers optimal solutions built on production drawings specifications, needs, and current conditions to help them achieve meeting their goals in business.

ACLPRESS boasts a large production capacity with numerous CNC machine tools including a CNC Gantry machining center CNC four-axis machining centers and CNC precise grinding machines. Additionally it a brake dies workshop to treat various spare parts quickly and accurately. Furthermore it houses a debugging centre is specifically designed to ensure fulfillment of orders from customers and the precise fulfillment of their requirements.