Metal objects, as a rule, are very precise and need to be correct in every detail. Bend tooling, which is one tool that helps with this! Some fixtures that help with shaping the metal (bending tooling) This is a key device for building things that must be incredibly precise, such as components of car components or aircraft components. So, let’s learn more about press brake and its significance in metalworking!

Bending and curving metal, each bend and curve needs to be precisely right. This is where bend tooling comes in very handy! Once you have your Bend tooling, metalworkers can create precise angles and shapes. This precision is essential for producing robust and secure components, such as components in automobiles or airplanes.[0] Precise metal work is critical, which is why companies like ACL offer only the best bend tooling to their customers. With the proper tools, metal workers can guarantee that their products are up to the high standards required by the automotive and aerospace industries.

From car parts to roofs and even furniture, firmly sheet metal is a commonly used material to make different things. However, to fabricate these pieces, the sheet metal must be AWS 179.5 Flipped and formed correctly. That’s where the bend tooling for sheet metal comes in! This style of tooling is specifically designed to help make sure every bend is spot on. As for examples of torque tooling, companies like ACL stock plenty of bipartite tooling for sheet metal work, including bend die inserts and clamps. This allows a smoother and more efficient process for metalworkers to create their desired shape.

Bend tooling is also used to bend tubes, in addition to sheet metal. Tubes are used in everything from plumbing pipes to metal furniture frames. Specialized pipe bending tooling is widely used to accurately bend tubes to various desired angles and curves. Mandrels and wipers are just a few of the options ACL provides for bending tubes. These tools guarantee rapid and accurate tube bending that leads metalworkers to produce quality products.

However, in some cases custom bend tooling is even more beneficial than standard bend tooling. When you get custom bend tooling, it can be designed to exactly fit on exactly what you need, which means that you can create objects with perfect angles and curves. This allows metalworkers to manufacture parts that work together, effectively and efficiently. ACL provides precision bending tooling built to each customers specific requirements, leading to enhanced performance and precision metal forming process. Shaving time and material using specific tools is a great asset in a busy workshop.

Bend tooling is one of the many methods used in the fascinating world of metal forming. Advanced bend tooling methods are essential knowledge for metalworkers seeking to produce truly awesome metal objects. Some of these are rotary draw bending, mandrel bending, etc. These techniques aid in creating complex shapes typically needed in modern designs. The training aims for customers to be able to master what is necessary for making precise precision objects in metal with these techniques. These skills help metalworkers to develop their craft and create superior products.

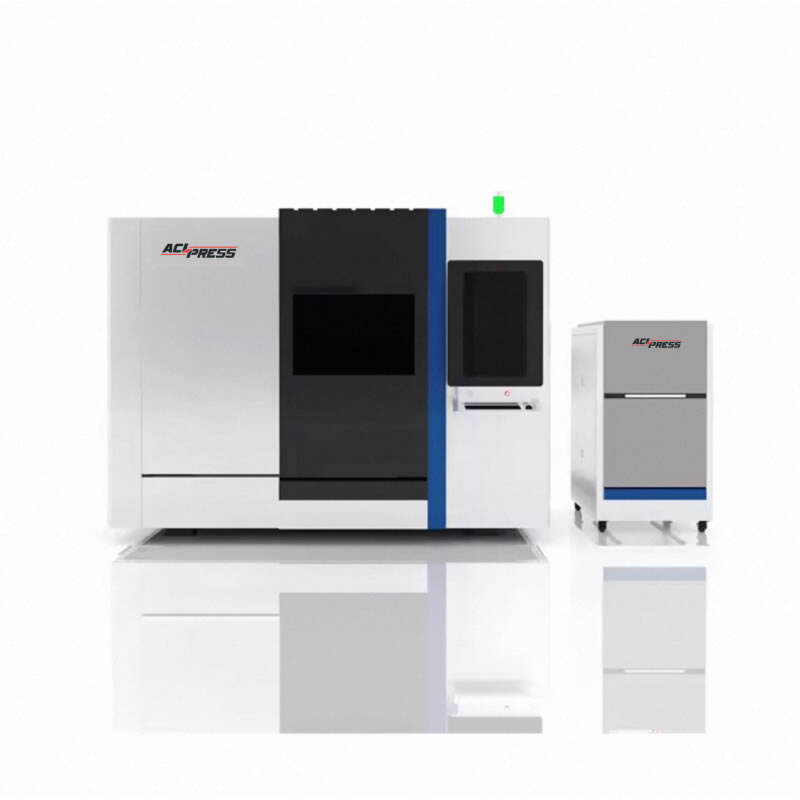

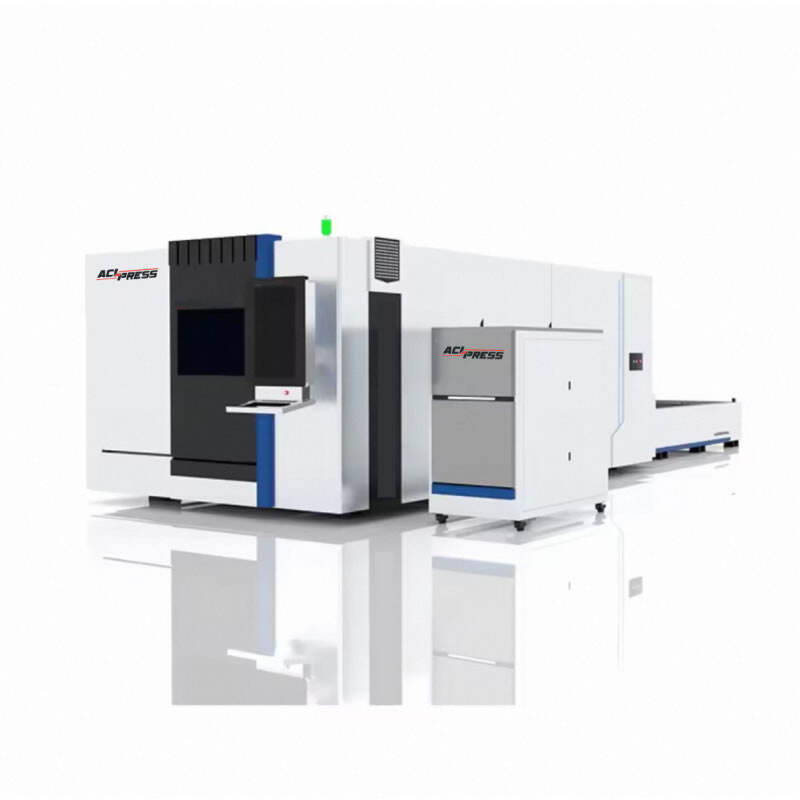

ACLPRESS a substantial production capacity due to its bend tooling which include a CNC gantry machine CNC 4-axis machines and CNC precision grinders. Additionally it a heat treatment workshop which handles various spare parts efficiently and accurately. The facility also houses a debugging centre ensures orders placed by customers are delivered on time and precisely.

ACLPRESS is actively involved in the field of steel bending for over 20 years. With bend tooling and sales knowledge, we can help our customers in resolving problems in a range of applications for our products. Furthermore, our technical staff provides 24/7 technical support, seven days a week, ensuring prompt and high-quality support to our customers.

ACLPRESS bend tooling exceptional processing and capability to customise products. It is well-versed in the specifics of the bending of sheet metal which allows it to provide customers optimal solutions built on production drawings specifications, needs, and current conditions to help them achieve meeting their goals in business.

ACLPRESS is not just home to the bend tooling of precision equipment for the processing of press brakes but also various precision inspecting tools to spot defects in the product, and ensure reliability and stability. We also offer a comprehensive after-sales support.