Hydraulic punching machine is a heavy automatic machine which is used to punch holes in metal sheet, it is very easy to use. For example, these machines excel at drilling holes accurately through metal sheets. Using a strong force known as hydraulic pressure, the machine can punch holes in even very steel sheets without the need for too much strength from the user. With this machine you can easily make perfect holes of various sizes and shapes.

Speed is essential when you are working with metal. You want to finish your work and go on to the next. Hydraulic punching machines enable you to complete your work at a fast pace. It is quite fast-paced, enabling you to get done with your tasks in a flash. Things this machine is designed to last and to do so without losing its quality and efficiency. If you work with metal and want to do your job faster and easier, you should probably take you time to use a hydraulic press brake machine . It greatly helps in increasing your overall productivity.

The most important advantage of bending dies for hydraulic press is that it saves your money and time. This means you won't need to invest hour upon hour into a single metal sheet — the machine will make quick work of it. So instead of twiddling your thumbs waiting for the machine to finish, you can keep doing the work that matters. Also, it needs less people to operate, which can save on labor costs.

Finally, these machines are very durable and require low maintenance. They are also very durable and built to last many years, which means you won't need to replace them constantly. These kinds of power tools are constructed to endure abrasive circumstances that are common of workshop environments, and therefore they are a dependable decision for metal fabricators.

A hydraulic punching machine (also called a punching press) automates hole creation. In simple terms, the machine assists you with making precise and exact holes, and you do not have to spend a lot of time or resources on it. Also, this machine minimizes the occasions where errors can occur when punching holes by hand. With hydraulic punching machines, punching holes in sheets has become much easier and less stressful for the worker doing it.

These hydraulic punching machines have various characteristics that are the best options for providing the hole to the metals. First, they are made to be operated minimally to enable anyone to use them, regardless of their experience. Second, they're crafted from high-quality materials that are durable. That means you can count on the machine to perform its tasks well for many years.

Third, third, the user interface, the machine is easy to use as well, even if a person used for the first time. This way there is a lower barrier of entry for anyone to quickly become proficient in machine usage, without confusion or intimidation. Finally, hydraulic punching machines come equipped with safety features ensuring you’re not injured when operating one.

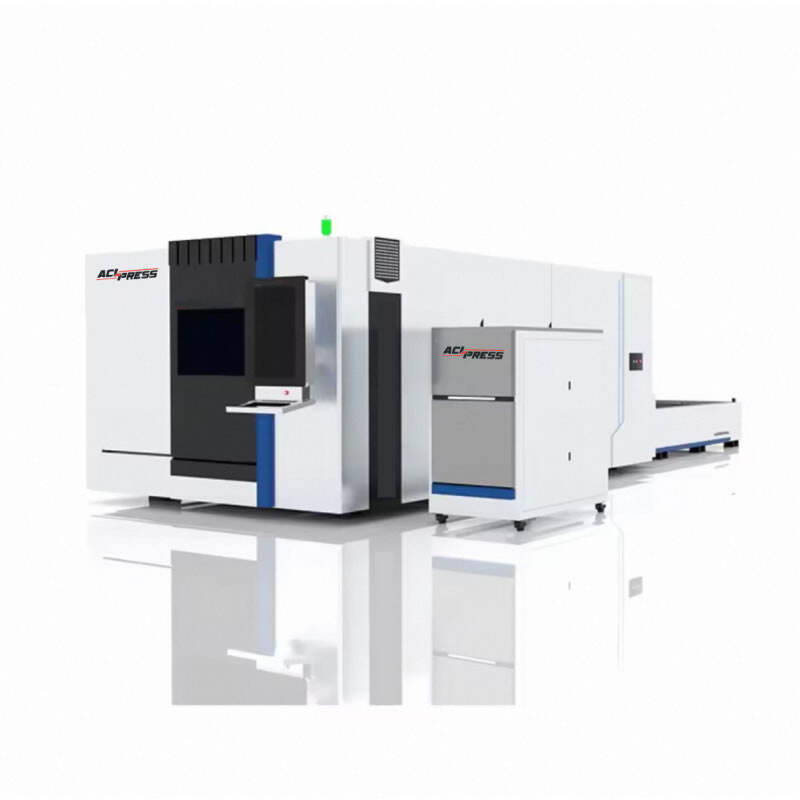

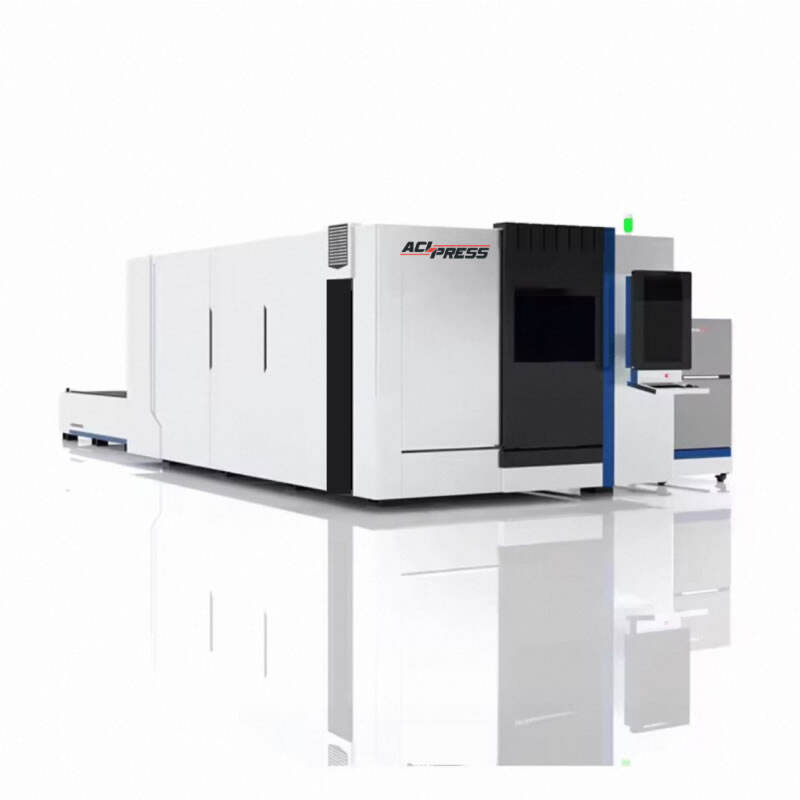

ACLPRESS hydraulic punching machine exceptional processing and capability to customise products. It is well-versed in the specifics of the bending of sheet metal which allows it to provide customers optimal solutions built on production drawings specifications, needs, and current conditions to help them achieve meeting their goals in business.

ACLPRESS is not just home to the hydraulic punching machine of precision equipment for the processing of press brakes but also various precision inspecting tools to spot defects in the product, and ensure reliability and stability. We also offer a comprehensive after-sales support.

ACLPRESS a substantial production capacity due to its hydraulic punching machine which include a CNC gantry machine CNC 4-axis machines and CNC precision grinders. Additionally it a heat treatment workshop which handles various spare parts efficiently and accurately. The facility also houses a debugging centre ensures orders placed by customers are delivered on time and precisely.

ACLPRESS has been active in the steel metal bending industry for over 20 years. We have hydraulic punching machine in sales and production, and we can assist customers in addressing and solve issues in numerous product types. Our team of experts provides round-the clock technical support 7/24 to ensure speedy and high quality service delivery.