NANJING ACL MACHINERY factory focused on R&D manufacuring shearing machine, bending machine, hydraulic press. Our machines have solid technical strength and advanced technology so that they are unique in domestic aviation, shipping, metallurgy and building industry.

There are a variety of options available to bend sheet metal, and all serve to accommodate a range of needs and capabilities. You can buy anything from a manual to full CNC making tube or pipe benders. Do hydraulic sheet metal bending machines have any advantages over the press brake?.AppCompatActivity700.8%"Hydraulic"Pressing brakes that can bend a huge ton and staff in order to maximize productivity, it is suitable for small volume-high mix production.If there is no one suitableDie castInstead of using auto-tandemI will be missingHydraulicIt seems that you do not need to choose with all staff handling. Manual machines, on the other hand, are favored by site-machines-leasing companies and small projects where a human touch and tactile accuracy is more important. Different types of sheet metal bending machines are key to identifying which products will work best for your application.

When selecting your sheet metal bending machine, there are a number of things you need to consider - the type of material used, its thickness, required angle of bend and production capacity. Heavy duty projects that require precision and efficiency of production line calls for the use of a CNC sheet metal bending machine. These machines provide accurate control over bending operations, both in the accuracy and repetition. Manual machines, on the other hand, are more flexible and can be less expensive for smaller jobs that don’t demand automated precision.

CNC sheet metal bending machines have advanced technology which lets them interpret -in a precise way- the order to be carried out. Using computer programming, operators can type in exact measurements and angles, ensuring perfect bends. Such precision is required in sectors which have very strict quality and tolerance requirements. CNC machines also often have high speed, which helps in providing fast production time for orders and hence can be used in mass production of goods. Equipped with automatic systems and on-line monitoring, CNC Sheet Metal Bending Machines offer a dependable way to bend metal accurately.

Hydraulic sheet metal benders are also available for high volume production and heavy use. These devices leverage hydraulic pressure to force the metal through a bending die without any trouble. Via hydraulic systems, operators can achieve high bend speeds and production rates. This speed saves more than waste of time and it increases productivity at the manufacturing end as well. A hydraulic sheet metal press brake for every application, ranging from a 50 to 200 ton capacity and.063" to.787" bending length.

CNC and hydraulic metal bending machines have sophisticated features for industrial applications but manual benders have their own benefits. These machines work by hand so that you can do exactly how and where you need it, as opposed to bending times which aren't sensitive or even regulated by a human operator. Manual machines are more fitting for applications that demand a personal touch and require certain amount of manual precision. -They are the best option for businesses who want to obtain lenses with a reasonable price. Manual sheet metal benders come with either stationary pads or movable clamps to hold the material in place.

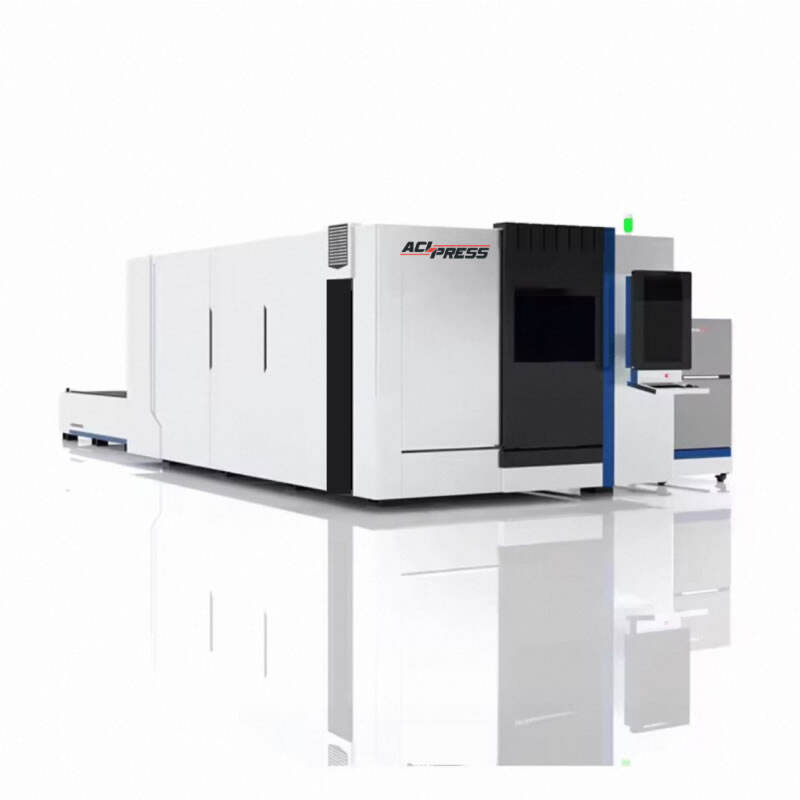

ACLPRESS is an expert for processing and customizing products. ACLPRESS is very familiar with the specifics of sheet-metal bent, which allows it to provide customers with optimal solutions types of sheet metal bending machine on their production drawings demands, requirements, and other specifications.

ACLPRESS is actively involved in the field of steel bending for over 20 years. With types of sheet metal bending machine and sales knowledge, we can help our customers in resolving problems in a range of applications for our products. Furthermore, our technical staff provides 24/7 technical support, seven days a week, ensuring prompt and high-quality support to our customers.

ACLPRESS possesses not only the most extensive selection of precision equipment for processing presses but also numerous precision inspecting tools to spot product issues, ensuring types of sheet metal bending machine and stability. In addition, we provide comprehensive service after-sales.

ACLPRESS boasts a significant production capacity due to its CNC machines like a CNC Gantry Machine CNC 4-axis machines and CNC precision grinders It also operates the heat treatment workshop which can process various spare parts fast and precisely In addition it houses a debugging centre that is specifically designed to ensure prompt completion of customer orders and the types of sheet metal bending machine of their needs