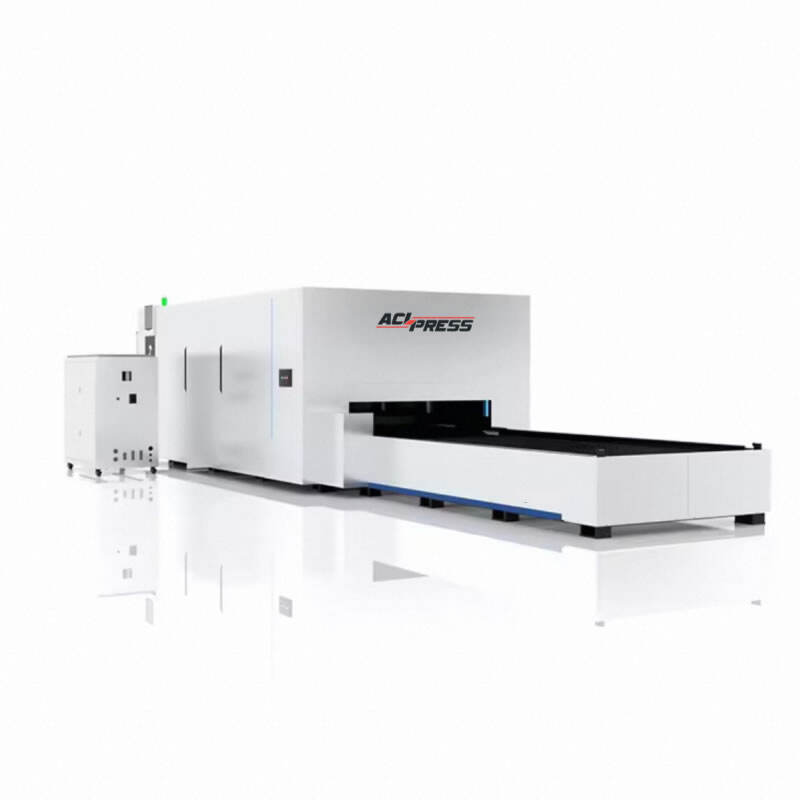

Our Profile Cutting Machine from ACL incorporates the latest technology for best results. It is not only easier but also extremely faster than the traditional methods of cutting with this cool machine. Time is among the most precious resources for businesses, it can translate to money. This is why our machine is specifically designed to help save YOU time and money!

Profile Cutting Machine does have numerous outstanding task in a factory. It can even cut materials of different composition, such as steel, aluminum and copper, in order to generate a multitude of shapes required for various products. This machine uses a neat process known as plasma cutting. This works by running electricity through gas to create a very hot light. This glowing hot light melts and also makes precision cuts that leave a beautiful edge.

This machine has revolutionized factory production, operating more quietly and with less waste in the cutting process. It can very fast, which means less noise in the workplace so it is a healthy environment for the workers. It also helps to keep our environment clean, which is important for the safety of all of us, as we produce less waste.

Our Profile Cutting Machine designed to enable factories to produce faster and precisely. This machine is designed to cut several parts at once without compromising the cutting accuracy. That means that factories are able to take on larger jobs and projects which allows them to become more profitable and to scale.

Parts of the device also contain a fast cutter fiche that assist to have fast and correct cuts. The machine makes cuts automatically, so each cut is identical, resulting in fewer errors and better quality products. Manufacturers can trust that the parts they manufacture will fit together seamlessly, which is extremely important.

Our Profile Cutting Machine Manufactures especially for Factories & manufacturers. It works automatically and accurately which makes production a whole lot easier and saves costs. Having the machine be able to run multiple jobs means that worker can have more important things to work on, such as the real details and not be bombarded by jobs.

Another really nice thing about this machine is it lends itself to less fixing and less maintenance. That reduces time out of production, and helps factories keep running smoothly. It also generates minimal waste, reducing the amount of raw materials that need to be cleaned up afterward, allowing companies to better manage their resources.

ACLPRESS boasts a robust production capacity includes numerous CNC machines which include a profile cutting machine CNC four-axis machining centers as well as CNC precise grinding machines. ACLPRESS also an industrial heat treatment facility treats various spare parts swiftly and precisely. It also houses an individual debugging center is designed to ensure fulfillment of customer requests and precise fulfillment of their requirements.

ACLPRESS profile cutting machine a broad range of precision equipment to process press brakes, as as a variety of inspection tools to detect problems with the product, and help ensure its dependability. Furthermore, we provide an extensive service after-sales.

ACLPRESS is a leader in the processing of products and modifying them. ACLPRESS is well-versed in the particulars of sheet metal bent, which allows it to offer customers the best solutions based on their production drawings, profile cutting machine, and conditions.

ACLPRESS is actively profile cutting machine in the steel metal bending industry for more than 20 years. With a wealth of sales and production experience, we can aid our customers in resolving problems across a variety of applications for our products. Our dedicated technical team provides all-hours technical support to ensure quick and high quality service delivery.