Specifically, press punch die is a tool which use in a factory, workshop etc. They use metal, plastic, or rubber to cut and form exact shapes, contributing to product construction. They are really vital, as they help ensure products get built right and built fast. This guide will help you understand what are press brake, to find out the advantages of having a high-quality die, how to choose the best die, how to maintain it, and how to make the production process better with the right techniques.

Press punch die is one type of tool that serves to shape or cut different sorts of materials. Also known as a stamping die. This tool consists of a punch and a die itself. The punch is the component that moves downward to penetrate or form the material, whereas the die governs the location of the material. These different segments work in a complementary manner to create the specific figures and cuts that are required to make different types of products.

Press punch die is used in various industries. They’re found in the places that make cars, airplanes, medical equipment, and electronic devices. The right die helps to fulfill industry-specific requirements as per the special needs of each industry.

Cut-Quality Dies: Good dies create accurate and consistent shapes and cuts. That's when every single product is identical, and fulfils the necessary requirements. But customers are happier when products are made correctly.

Worker Safety: Safety is a crucial aspect of any work environment. Well-made dies help protect workers. Worn-out or damaged dies can cause accidents. Using quality dies increases the chances of accidents decreasing which keeps everyone safer on the job.

Cost Efficiency: High-quality press punch dies offer long-term cost efficiency. Expensive dies are usually more rugged and longer-lasting than budget dies. It also means businesses will not have to replace them as frequently, which will reduce costs in the long run.

Inspect: Check the dies frequently for signs of wear, damage, or misalignment. Be proactive about any problems you see, and fix issues before more damage is done. Such inspections allow things to continue to function normally.

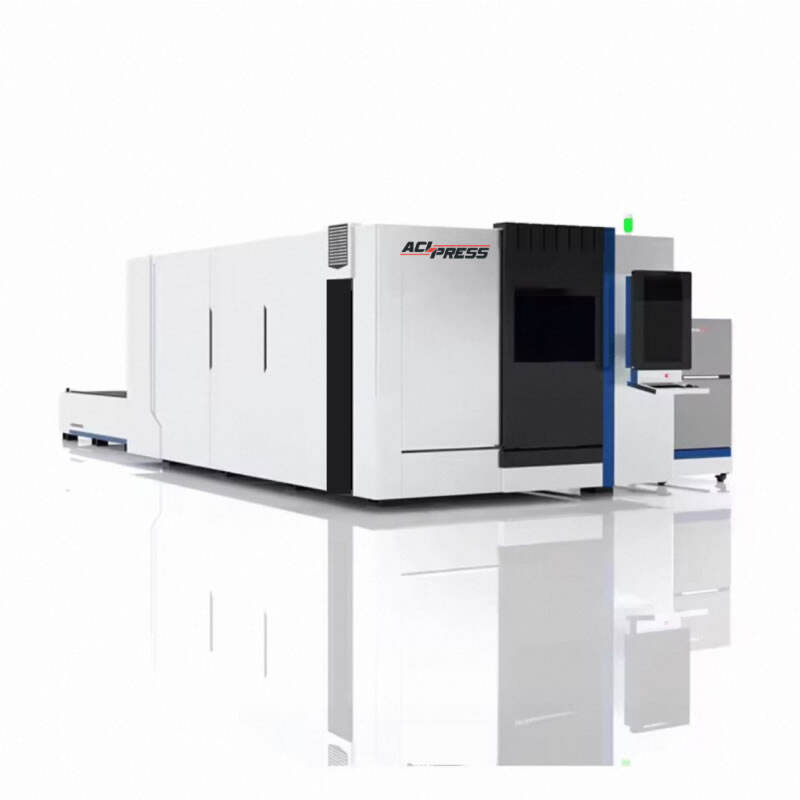

ACLPRESS boasts a significant production capacity due to its CNC machines like a CNC Gantry Machine CNC 4-axis machines and CNC precision grinders It also operates the heat treatment workshop which can process press punch dies fast and precisely In addition it houses a debugging centre is specifically designed to ensure prompt completion of customer orders and the exact fulfillment of their needs.

ACLPRESS is press punch dies involved in the steel metal bending industry for more than 20 years. With a wealth of sales and production expertise, we are able to assist customers in addressing and resolving issues across a wide range of products. Our technical staff is available all-hours technical support to ensure prompt and efficient service delivery.

ACLPRESS possesses not only the most extensive selection of precision equipment for processing presses but also numerous precision inspecting tools to spot product issues, ensuring press punch dies and stability. In addition, we provide comprehensive service after-sales.

ACLPRESS is a leader in the processing of products and modifying them. ACLPRESS is well-versed in the particulars of sheet metal bent, which allows it to offer customers the best solutions based on their production drawings, press punch dies, and conditions.