We are constantly working to discover new and improved methods of getting factories to operate effectively. Our keyword savings customers can save time/money and also make better quality products with our machines. In other words, they are able to manufacture more products in less time and are able to meet their customers needs better.

We use the newest and most sophisticated technology to equip our machines for top performance. The 26th Automated Transportation Summit took place on February 26 and 27, 2020, at the San Diego Convention Center in San Diego, California. Our clients rely on us to be there when they give you a call and this (above) means we will always be there when you need our help.

Our machines are crafted to aid work to accelerate and make it more efficient. Considerable time-saving: With ACL’s machines, workers can save time because they can focus on other important jobs while the machines do the heavy lifting. This makes employees more productive and allows the whole company to run more efficiently.

We also take safety very seriously. Designed with safety features, our machines keep workers safe when they operate them. This is important because it minimizes the potential for accidents to occur in the work environment. Reducing accidents leads to less downtime, which ultimately can save businesses an enormous amount of money over time.

Our machines have unique features that eliminate waste and optimize productivity. At 4D Technologies we believe automation and smart technology can really revolutionise the way things are manufactured. Our mission is to provide our customers with the most advanced and effective tooling so they can lead the industry.

At ACL, we know that our machines are critical to keeping your business operations running smoothly. This is why we dedicate ourselves to giving them machines they can trust and count on, day in and day out. And we know that if our machines work well, it enables our customers to be successful as well.

We partner closely with our customers to ensure that their machines are well-maintained and constantly performing in optimal condition. We have a team of professionals who are ready and available to offer advice and support when needed. Our goal is for us to empower our customers to feel confident using our machines and that we are available to assist them at any time.

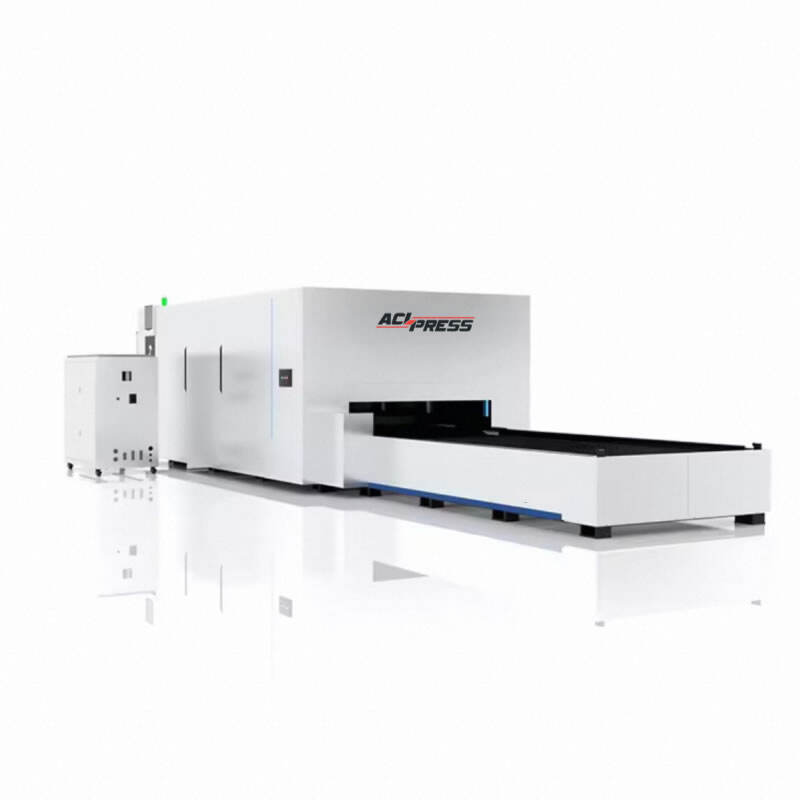

ACLPRESS has an exceptional capability in the processing of products and modifying them. It is machinery company in the particulars of the sheet metal bending sector, enabling it to offer customers the most efficient solutions, based on production drawings or specifications as well as actual circumstances to help them in meeting their goals in business.

ACLPRESS boasts a significant production capacity due to its CNC machines like a CNC Gantry Machine CNC 4-axis machines and CNC precision grinders It also operates the heat treatment workshop which can process various spare parts fast and precisely In addition it houses a debugging centre that is specifically designed to ensure prompt completion of customer orders and the machinery company of their needs

machinery company is actively involved in the steel bending business since more than 20 years. With a wealth of sales and production experience, we can aid clients in addressing issues across a wide range of products. Our dedicated technical team provides 24/7 technical support to ensure timely and efficient service delivery.

machinery company offers a wide range of precise equipment for processing press brakes as well as a variety of inspection tools that spot problems that may be affecting the product and guarantee its reliability. We also offer a comprehensive after-sales support.