Ever wondered how toys, clothes and even cars are made? They are all machine made! The machine as a powerful tool, enabling humans to create things faster and more efficient than we could by hand. At ACL, we supply the latest machines to help transform manufacturing in factories across the globe.

Our machines use the latest technology to manufacture a wide range of products in any factory, in an efficient and effective way. They can do work that would be difficult for humans or would take too long. That allows products to be made more quickly and with fewer errors — something we know is critical to customers. It also means workers are able to do other heavy lifting while the machines do the hard work on their behalf. Which makes business operations run smoothly and efficiently.

Different industries require different types of machinery. At ACL, we know this, in fact the best, and provide great solutions for businesses of all size. We have the best machine for each job regardless if it is the automotive industry where cars and trucks are made, the food industry where snacks and drinks are made, or the construction industry where buildings are built.

There are some businesses that need powerful machines that can hoist and transport large objects, like construction materials. Some require machines that will prepare food effectively and safely, delivering food to the point that people can start consuming it. Varying jobs, ACL has machines specifically aimed to assist in all these diverse situations.

It will allow machines to be much smarter than they currently are. They will be able to talk with one another and collaborate to produce things even quicker and better. This teamwork between machines will allow factories to make more items at the same time, without waiting for each step to be completed one after the other. They are also more planet friendly: these machines will consume less energy and generate less waste.

They are complex tools requiring precise maintenance and logistics. ACL machine can run at the peak after reliable service and maintenance. We also work with an experienced team of technicians who can identify and resolve any issues that arise in a timely manner, keeping your operations running smoothly.

Ensure regular check-ups—a very essential aspect to keep machines working efficiently, preventing breakdowns. We can also provide them with regular maintenance services, which will help us detect any issues before they grow larger and more expensive to repair. Taking this preventative action keeps our hardware running smooth for extended periods, and allowing companies to fearlessly depend on our hardware.

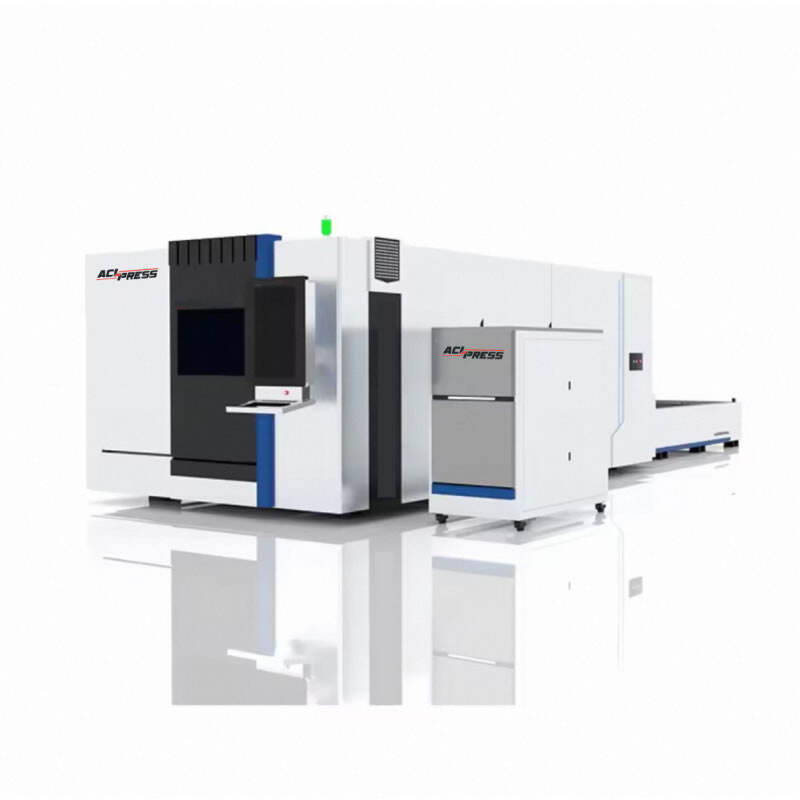

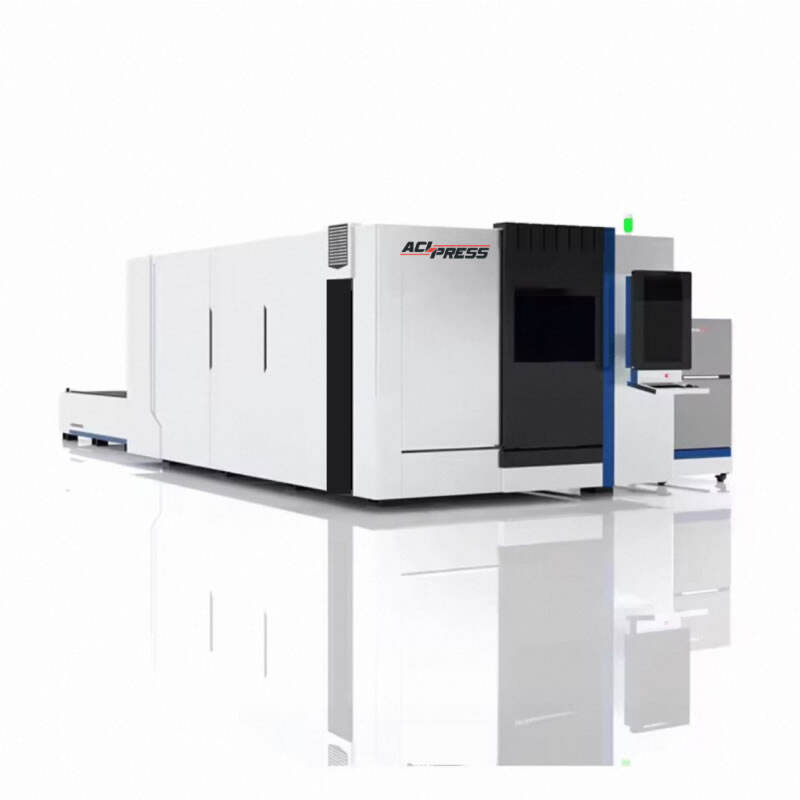

ACLPRESS is not just home to the machinery business of precision equipment for the processing of press brakes but also various precision inspecting tools to spot defects in the product, and ensure reliability and stability. We also offer a comprehensive after-sales support.

ACLPRESS is an expert for processing and customizing products. ACLPRESS is very familiar with the specifics of sheet-metal bent, which allows it to provide customers with optimal solutions machinery business on their production drawings demands, requirements, and other specifications.

ACLPRESS is actively involved in the field of steel bending for over 20 years. With machinery business and sales knowledge, we can help our customers in resolving problems in a range of applications for our products. Furthermore, our technical staff provides 24/7 technical support, seven days a week, ensuring prompt and high-quality support to our customers.

ACLPRESS boasts a machinery business capability which includes a wide range of CNC machine tools such as a CNC Gantry machining center CNC 4-axis machining centers as well as CNC precision grinding machines Additionally it a heat treatment workshop processes various spare parts quickly and accurately In addition it houses a debugging centre is specifically designed to ensure the completion of customer orders as well as the precise fulfillment of their requirements