ACL takes great pride in its specialty machines that aid the business in getting very precise cuts of metal. These machines employ some of the latest technology on the market that grants them the ability to perform precise cuts. Everything is cut to size, so all the components are made perfectly to spec. With this technology, manufacturers know the components they produce will fit together with accuracy, ensuring better performance and longevity.

ACL’s machines not only cut accurately, they also allow workers to do their jobs in far less time. If workers use machines to cut and shape metal, it can save time and effort. For them, it works out as they don't need to waste hours doing their job manually cutting metal. Automating this process enables organizations to make even more with less time, helping them fulfill consumer needs promptly. This leads to a more efficient production process and in turn allows for more scalable and streamlined companies.

When manufacturers use machines owned and operated by ACL, they create parts that meet exacting specifications for countless industries. Such parts are very very crucial in domains like airplanes, cars, buildings etc. In the aerospace industry, for example — to protect the safety of passengers, the parts need to be manufactured with high precision. Another such industry is the automotive sector where flawless components are essential for automobiles to function. ACL's cutting technology also helps manufacturers ensure that their products are safe and reliable, which is essential for maintaining customer satisfaction.

Our state-of-the-art machines can fabricate your metal products in countless ways. They are capable of creating a wide range from small, detailed designs to large and complex assemblies. This means companies can really think out of the box and experiment without the fear of pushing their hardware too far. Manufacturing is limited only by the imagination — with the machines from ACL. They were able to experiment, innovate, and still deliver high quality products that enhance the lives of their customers. In the current market, this adaptability is crucial for ensuring competitiveness.

Our machines are also designed to cut metals while saving materials, which is another one of their best features as well. By cutting less, businesses will save money because they will have less materials to purchase. It is also better for the planet because it produces less waste. When the machines of ACL cut, they know to make each piece right, so fewer extra materials are used. This is how our technology helps businesses be responsible and sustainable while achieving their production goals.

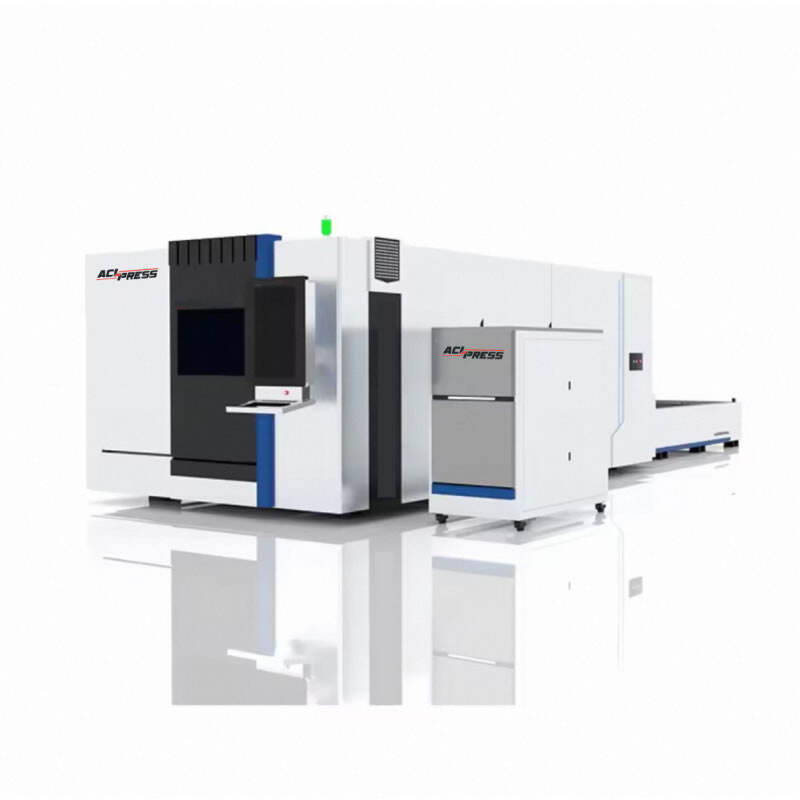

ACLPRESS is actively involved in the field of steel bending for over 20 years. With machine cutting metal and sales knowledge, we can help our customers in resolving problems in a range of applications for our products. Furthermore, our technical staff provides 24/7 technical support, seven days a week, ensuring prompt and high-quality support to our customers.

ACLPRESS has exceptional capabilities in processing and customizing products. ACLPRESS is well-versed in the particulars of sheet metal bends, which allows it to offer customers the most efficient solutions in line with their production plans machine cutting metal, requirements, and other specifications.

ACLPRESS boasts a large production capacity with numerous CNC machine tools including a CNC Gantry machining center CNC four-axis machining centers and CNC precise grinding machines. Additionally it a machine cutting metal workshop to treat various spare parts quickly and accurately. Furthermore it houses a debugging centre is specifically designed to ensure fulfillment of orders from customers and the precise fulfillment of their requirements.

ACLPRESS has a large range of high-precision equipment that can process machine cutting metal, as well with a range of inspection tools that find problems with the product and ensure its reliability. Additionally, we offer comprehensive after-sales support.