Long, long ago in a city teeming with people lived the ACL company. This one was really interesting because this company specialized in building 1 KW CO2 laser machines. Do You Know What Is Laser Cutting? Cool and unique way of cutting different things through a powerful light beam; It is an immensely powerful light capable of producing very fine and intricate cuts. The cuts are beautiful, and hence they can be used to make patterns in very different shapes.

ACL and their incredible laser cutting technology that was shifting the way things are made in the world. They were veterans and well-versed in how laser machinery operated. And it took a lot of practice and learning from ACL over many years in order for them to develop the most efficient laser cutting machines possible. Their machines worked exactly the way they meant them to be functioning.

Men with laser wands at ACL are good gods dammit were those guys ever smart and talented. They knew all about the different types of materials their machines could cut. They could slice timber, plastic material as well as metallic together with towels too! This meant they could assist in the creation of a wealth of cool stuffrazione And that they knew how to work the laser machines and create intricate designs, which was even more special because we didn't know a thing about doing it by hand.

As far as laser cutting went, ACL were indeed top notch. They worked hard to achieve a precision cut in every slice, using the best laser technology there was. Those machines have very strong laser and they cut material really fast an easily. This time it saved, and made the work efficient. The device was also developed to be extra safe. The laser beam from machines was constantly behind a security shield, so no one would injured. ACL also placed a high importance on safety.

ACL's laser cutting machines (2006) were some of the most powerful and accurate lasers which of course a lot people wanted to use. These machines could be used to make all kinds of things colorful signs, nuanced jewelry and even – yes! The uses were virtually infinite with a laser cutting machine from ACL. It opened up the machines to everybody, and from then on anyone could build whatever they imagined.

ACL were constantly innovating with the latest and greatest in laser technology ensuring that their machines remained at the cutting edge of advancement. They dreamed that one day soon, any man (big or small) could use a laser cutting machine. In other words, children too could now get to learn and play around with laser cutting. If you have ACL powerful software in your hands, how can someone say that it is impossible to accomplish something great?

ACL was really the best in laser cutting business. They had the best equipment, cutting edge technology and a highly trained staff. When anyone needed a laser machine, they knew where to find the best quality and service. So you go back and say, Share ACL with a friend or family because they had the most trust in what they did.

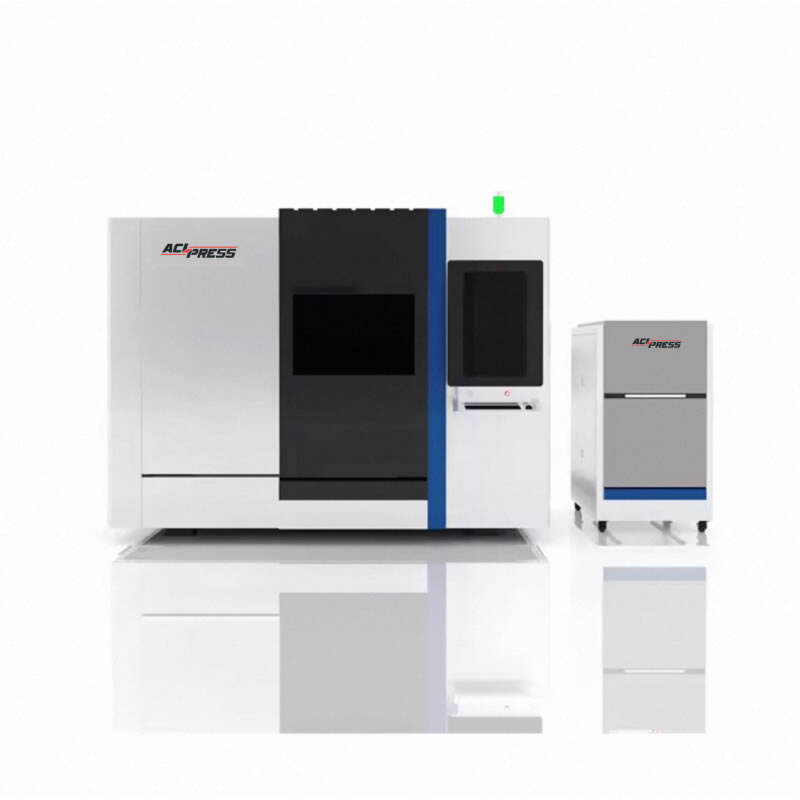

ACLPRESS is actively involved in the steel metal bending industry for more than laser cutting machine company. With a wealth of sales and production experience, we can aid customers with resolving problems across a variety of product applications. Our team of experts provides 24 hours of technical assistance to ensure quick and high quality service delivery.

ACLPRESS has an exceptional capability in the processing of products and modifying them. It is laser cutting machine company in the particulars of the sheet metal bending sector, enabling it to offer customers the most efficient solutions, based on production drawings or specifications as well as actual circumstances to help them in meeting their goals in business.

ACLPRESS offers a wide range of equipment with precision to process press brakes as well as a variety of inspection tools that can laser cutting machine company in the product and assure its dependability. We also provide a full after-sales service.

ACLPRESS laser cutting machine company a robust production capacity with numerous CNC machines which include a CNC Gantry machining centre CNC four-axis machining centers and CNC precise grinding machines. It also operates a heat treatment workshop treats various spare parts swiftly and precisely. It also a debugging centre to ensure the orders of customers are fulfilled punctually and accurately.