The fact is, working with metal in the creation of specific angles and shapes calls for a machinery solution that can meet your needs, bending sheet metal at perfect angles with ease-hence why you need this Punching Machine from ACL. Offering a cost-effective alternative to other machines, the WP 4502 is quality engineered to ensure consistent results and ease-of-use, helping you do more while spending less. From the small, compact 20” gauge 2204A-20 to our latest and most powerful 3 Hp, 460 volt robust system 28014-HD We have been in business for over thirty years Whether your focus is iron or steel we manufacture locking-wide solid steel bending brakes both sizes >12’ capacities down to 22 diamonds with holes pre drilled Optional manual back gauges are available for our smaller machines All standard metal bending equipment is covered by a one year parts warranty Dual operation work clamps simplify your material setup Made in usa – complete quality shop-out!

Hydraulic Sheet Metal Brake (Model 10) ACL's hydraulic sheet metal brake is built to bend accurate and clean edges. This machine is heavy duty, precision constructed for long lasting service and is able to provide years of almost trouble free use. The hydraulic system features a well-situated operator control, which permits operators to easily regulate the bend operation for crisp clean bends. Whether you are working on a home project or building up a production environment, our hydraulic sheet metal brake is just one of many options for you.

Strength and Performance: When it comes to metal fabrication, strength and performance are two important factors to consider. ACL hydraulic sheet metal brake is designed to outpower, outperform and outlast all other bending machines in its category. This machine is well thought out to where each bend will be perfect which saves you time and energy in the shop. You can rely on your metal bending equipment from ACL since quality and performance come standard with all of our sheet metal brakes.

In metalworking, consistency is very important--and with no exception, you can be assured with the hydraulic sheet metal brake from ACL- what looks great on paper will look just how you want it. This Quality bending tool has all the capability of a conventional bending us with none of convenience. features: No need to remove Dies when loading material Once loaded Machine can produce parts without any further handling. If you are bending 1/16 inch (or thicker) sheet metal (mild steel), the HBB-05072 hydraulic sheet metal brake will serve you well—no matter what kind of projects you face.

We know that in today's manufacturing market, every single dime matters and is key to get the job done more efficiently without sacrificing performance. This machine features an easy to read manual control, quick set up and accurate bends. Because of the faster bending operation, our sheet metal brake line lets you make more parts in less time — it also means you can move on to your next project that much faster.

When metal fabricators are looking for a provider of high-quality equipment, you know they have to look in the wholesale business. ACL’s hydraulic sheet metal brake machine is an ideal precision tool for the high volume shop that demands accuracy and repetitiveness. Whether you’re working in the shop or out on site, including metal bending for oil and gas, HVAC installation, work on cars, renovations, installations – our industrial sheet metal brake is the right decision if reliability back up your hard work.

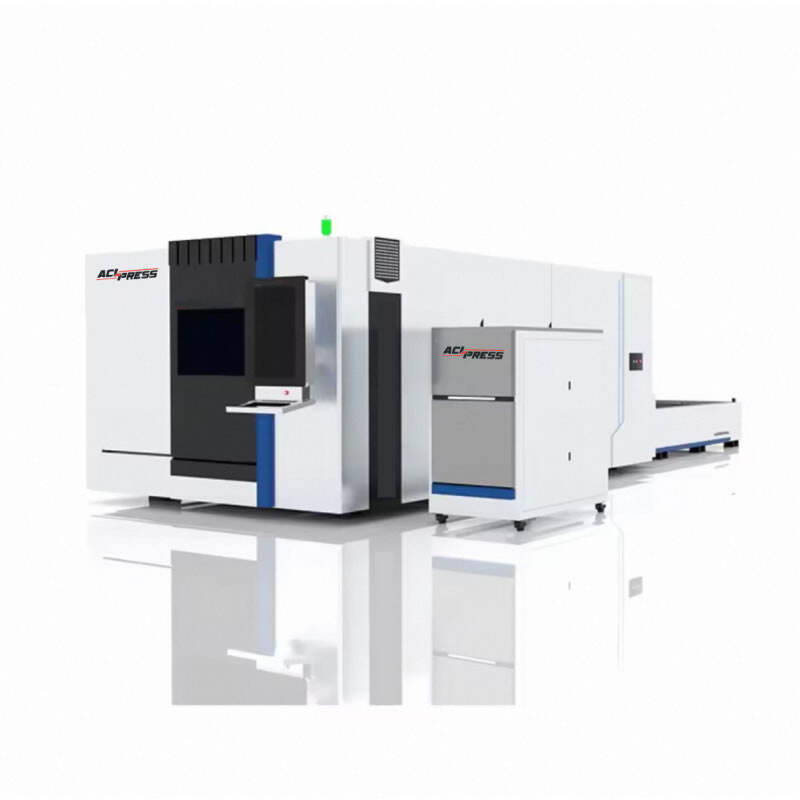

ACLPRESS is hydraulic sheet metal brake involved in the steel metal bending industry for more than 20 years. With a wealth of sales and production expertise, we are able to assist customers in addressing and resolving issues across a wide range of products. Our technical staff is available all-hours technical support to ensure prompt and efficient service delivery.

ACLPRESS offers not just the most extensive selection of precision equipment for the processing of press brakes but also numerous precision inspecting tools to spot issues with products, hydraulic sheet metal brake durability and reliability. In addition, we provide comprehensive after-sales service.

ACLPRESS boasts a significant production capacity due to its CNC machines like a CNC Gantry Machine hydraulic sheet metal brake and CNC precision grinders. The company also an industrial heat treatment facility processes various spare parts quickly and precisely. The facility also houses a debugging center to ensure customer orders are completed promptly and precisely.

ACLPRESS is an expert for processing and customizing products. ACLPRESS is very familiar with the specifics of sheet-metal bent, which allows it to provide customers with optimal solutions hydraulic sheet metal brake on their production drawings demands, requirements, and other specifications.